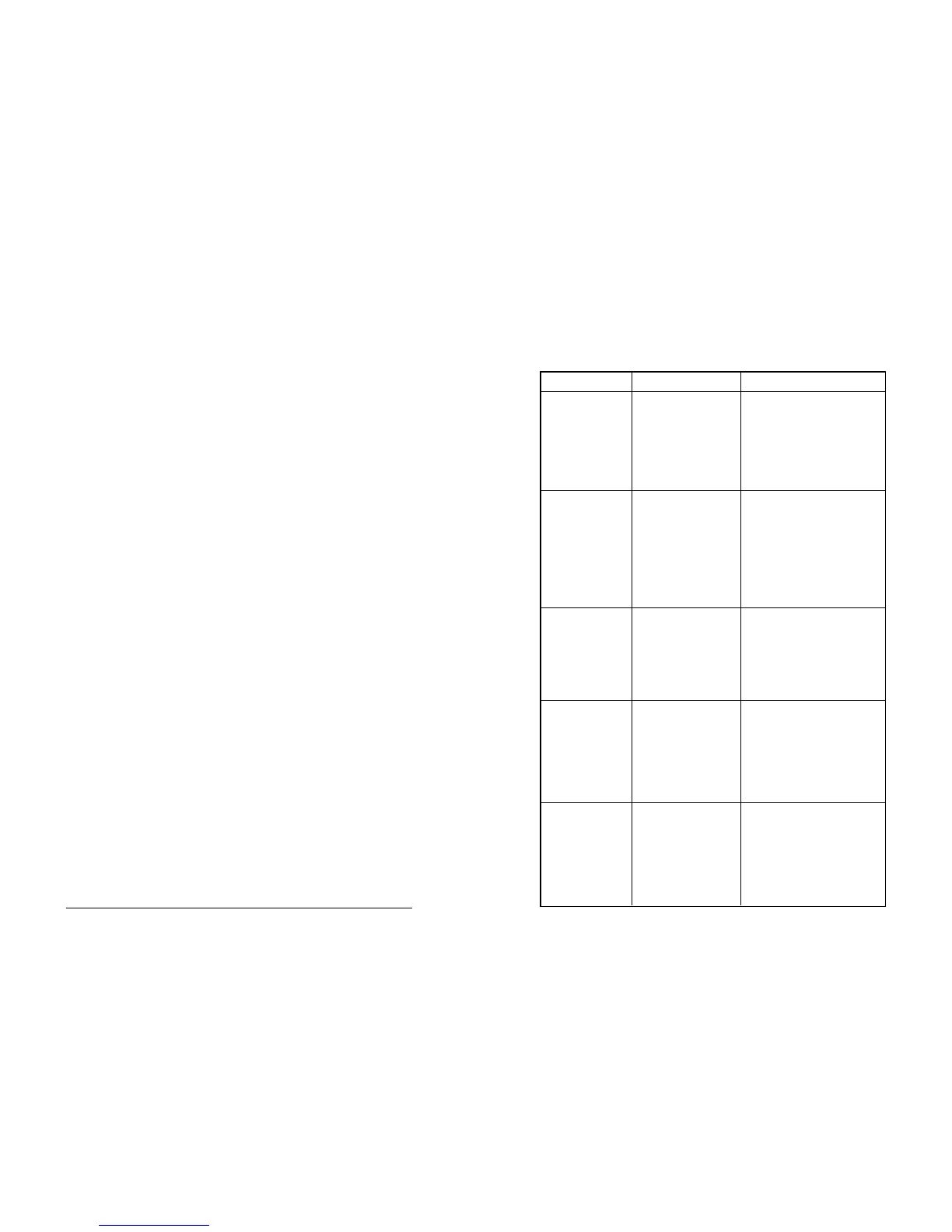

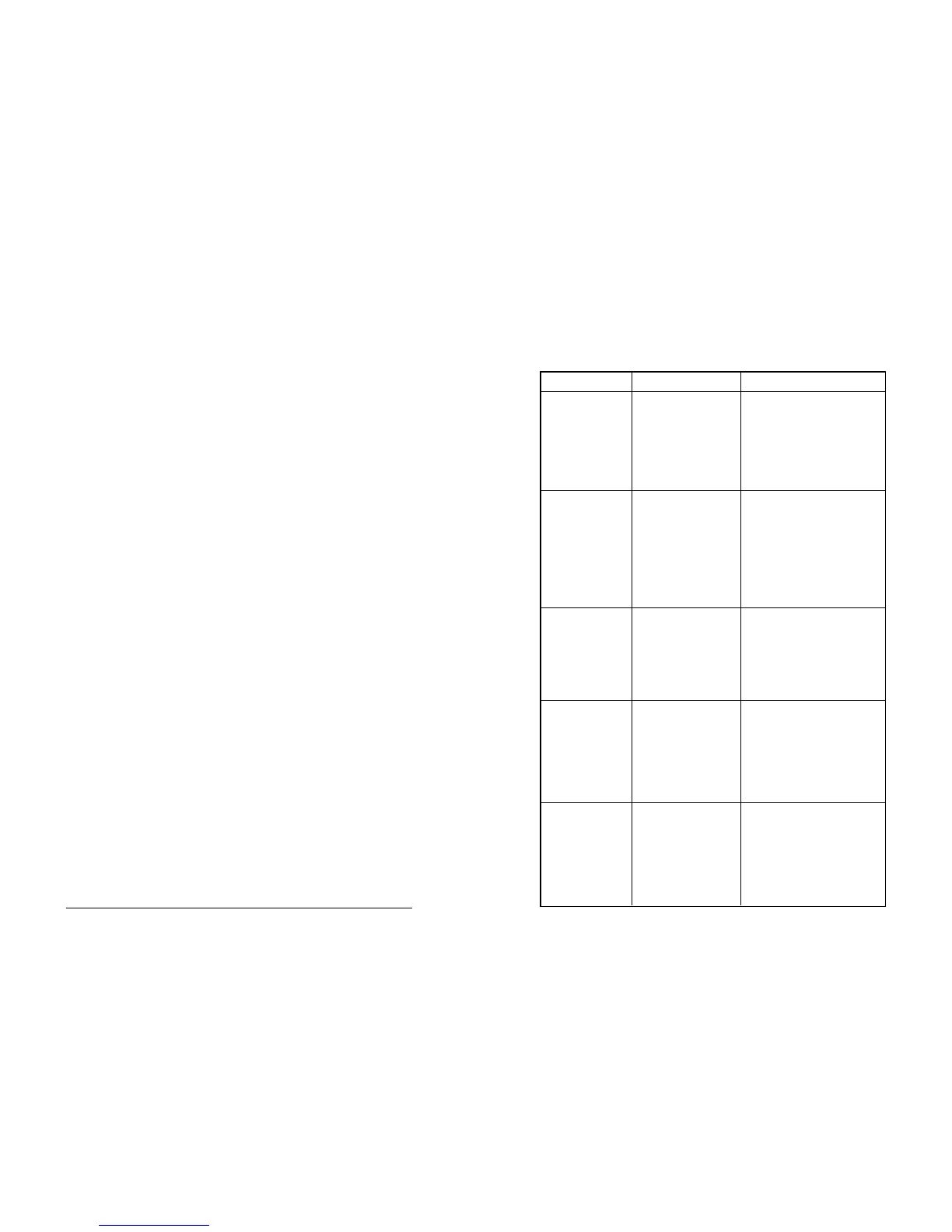

Fault Finding

Note: All servicing and repairs must be undertaken by a competent person,

familiar with unvented systems.

Fault Possible Cause Solution

Over temperature The thermostat has failed Reset. If the cut-out operates

cut-out operates again isolate the unit and contact

The thermostat is set at the installer. Note: Isolate the

too high a temperature electrical supply before

removing the electrical cover

panel and ensure that the

panel is correctly replaced and

secured before reconnecting

Regular, intermittent Loss of pressure from the Isolate the heating system and

water discharge from expansion vessel the mains cold water supply.

tundish Partly drain the unit. Recharge the

expansion vessel to the specified

pressure and re-commission.

Thermostat failure Isolate the heating system and

check thermal controls when

discharge ceases. Replace

thermostat if faulty.

Continuous water Pressure reducing valve Check with pressure gauge and

discharge from not operating correctly replace as necessary

the tundish

P&T relief valve not Check and replace if faulty

operating correctly

Expansion relief valve Check and replace if faulty

not operating correctly

No water flow from Cold water mains supply Restore mains supply to the heater

hot taps isolated

Integral line strainer in Check and clean as necessary

pressure reducing valve

has become blocked

Pressure reducing valve Refit correctly with arrows in

incorrectly fitted direction of flow

Water from hot taps Power supply not Check and switch on

is cold switched on

Over temperature See fault "Over temperature

cut-out has operated cut-out operates" above

Faulty element Check and replace as necessary

Thermostat failure Check and replace as necessary

AP3/30, AP3/50, AP3/80, AP3/100 Installation Instructions 12

are specifically excluded under the terms of the warranty. To reduce

lime-scale formation to a minimum the unit should always be operated at

the lowest convenient temperature. The ‘E’ temperature setting is

recommended

10. If the unit has been commissioned and is to be unused for more than

two weeks with the power supply still connected the thermostat should

be set to ‘*’ to maintain a temperature of approx. 9ºC and protect the unit

from freezing. Note: this protection does not extend to connecting

pipework. It is recommended that the cold supply is turned off

and several litres of water drawn off through a hot tap. Note: The cold

supply must be re-opened prior to use. If power has been

disconnected it is recommended that the unit is drained (see draining)

11. The Zip Aquapoint is fitted with a sacrificial anode to provide additional

protection against corrosion. Gradual erosion of the sacrificial anode

will occur depending upon local conditions which in extreme cases

may cause rapid erosion of the anode resulting in particles being

deposited as a residue. The Aquapoint should not, therefore, be used

in applications where water quality is critical. Regular preventive

maintenance inspections are vital to achieve optimum performance and

durability of the appliance. The condition of the anode should be

checked regularly by an authorised Zip service provider as part of the

preventive maintenance programme.

Schedule

It is recommended that all key components of the heater should be inspected

on a regular basis, no greater than twelve monthly intervals, for continued safe

and efficient operation. The inspection should be carried out by a competent

person familiar with unvented systems and the components to be inspected

should include the following:

1. Expansion relief valve. Check for correct operation

2. T&P relief valve. Check for correct operation

3. Check expansion vessel pressure – refer to label on vessel for correct

pressure

4. Inspect integral line strainer and clean as necessary

5. Check that the discharge pipework is free of any obstructions

6. Check that all electrical connections are tight

7. Check condition of the sacrificial anode by disconnecting the wire

between the anode and vessel and verifying that the current between

anode and vessel exceeds 0.1mA ensuring that the wire is re-connected

afterwards. If the current between anode and vessel does not exceed

0.1mA the anode should be checked visually and replaced if necessary

11 AP3/30, AP3/50, AP3/80, AP3/100 Installation Instructions

Loading...

Loading...