The HVAC system is sized to handle the load of the entire home

or building. Because of this, when all the zones are not calling, the load

to the HVAC system can diminish below its designed capacity. Left

unchecked, the HVAC unit could freeze up or overheat. To compensate

for this, the Digitract 4-2 is furnished with a built in Capacity Controller.

The basic function of the Capacity Controller is to monitor the leaving air

temperature and cycle the unit off when the air is out of operating range

and, after a minimum four minute time delay, turn the unit back on when

the air temperature has returned within operating range. Additionally, for

heat pumps the Capacity Controller will turn on the heat pump auxiliary

heat if the coil leaving air temperature is not hot enough in heat mode.

W1 Heat Operation – Upon a heat call, the controller will energize W1

if the leaving air temperature is less than 145°F. W1 will deenergize if

the LAT exceeds 145°F. The W1 LED will then cycle off and the PWR LED

will begin to flash indicating a capacity control cutout. After a 4-minute

recycle timer has completed, W1 will energize if the LAT is below 145°F.

W2 Heat Operations – After W1 has operated continuously for 4

minutes and the LAT is 120°F or less, W2 will energize. W2 will remain

energized until the LAT rises above 135°F or if all heat calls become

satisfied. The W2 LED will then cycle off.

Y1 Heat Operation – Upon a heat call, the controller will energize Y1

and operate with a minimum run time of 4 minutes, regardless of the leaving

air temperature. At the completion of the minimum run time, if the

leaving air temperature rises above 120°F, Y1 is deenergized; the Y LED is

off and the PWR LED will flash. G will remain energized, upon which the

leaving air temperature is rechecked after 4 minutes. If the leaving air

temperature has recovered to 120°F. or lower Y1 will recycle and the

PWR LED will stop flashing. If the reversing valve jumper is in the

O position, the O/B output will be energized simultaneously with Y,

indicated by the O/B LED.

Y2 Heat Operation – After 4 minutes of continuous Y1 run time, the

leaving air temperature, LAT is checked. If the LAT is below 95°F., Y2 will

be energized and the Y2 LED will illuminate. Y2 will cycle off when the

LAT rises above 105°F., or when all heat calls are satisfied.

Auxiliary Heat – After 8 minutes of continuous Y1 operation the leaving

air temperature, LAT is checked. If the LAT is below 88°F., W2 will be

energized and the W2 LED will illuminate. W2 will cycle off when the LAT

rises above 97°F., or when all heat calls are satisfied.

Y1 Cool Operation – Upon a cool call, the controller will energize Y1

and operate with a minimum run time of 4 minutes, regardless of the

leaving air temperature. At the completion of the minimum run time, if

the leaving air temperature drops below 45°F., Y is deenergized; the Y

LED is off and the PWR LED will flash. G will remain energized, upon

which the leaving air temperature is rechecked after 4 minutes. If

the leaving air temperature has recovered to 45°F. or greater, Y will be

reenergized and the PWR LED will stop flashing. If the reversing

valve jumper is in the O position, the O/B output will be energized

simultaneously with Y, indicated by the O/B LED.

Y2 Cool Operation – After 8 minutes of continuous Y1 run time, the

leaving air temperature, LAT is checked. If the LAT is above 60°F., Y2 will

be energized and the Y2 LED will illuminate. Y2 will cycle off when the

LAT drops below 50°F., or when all cool calls are satisfied.

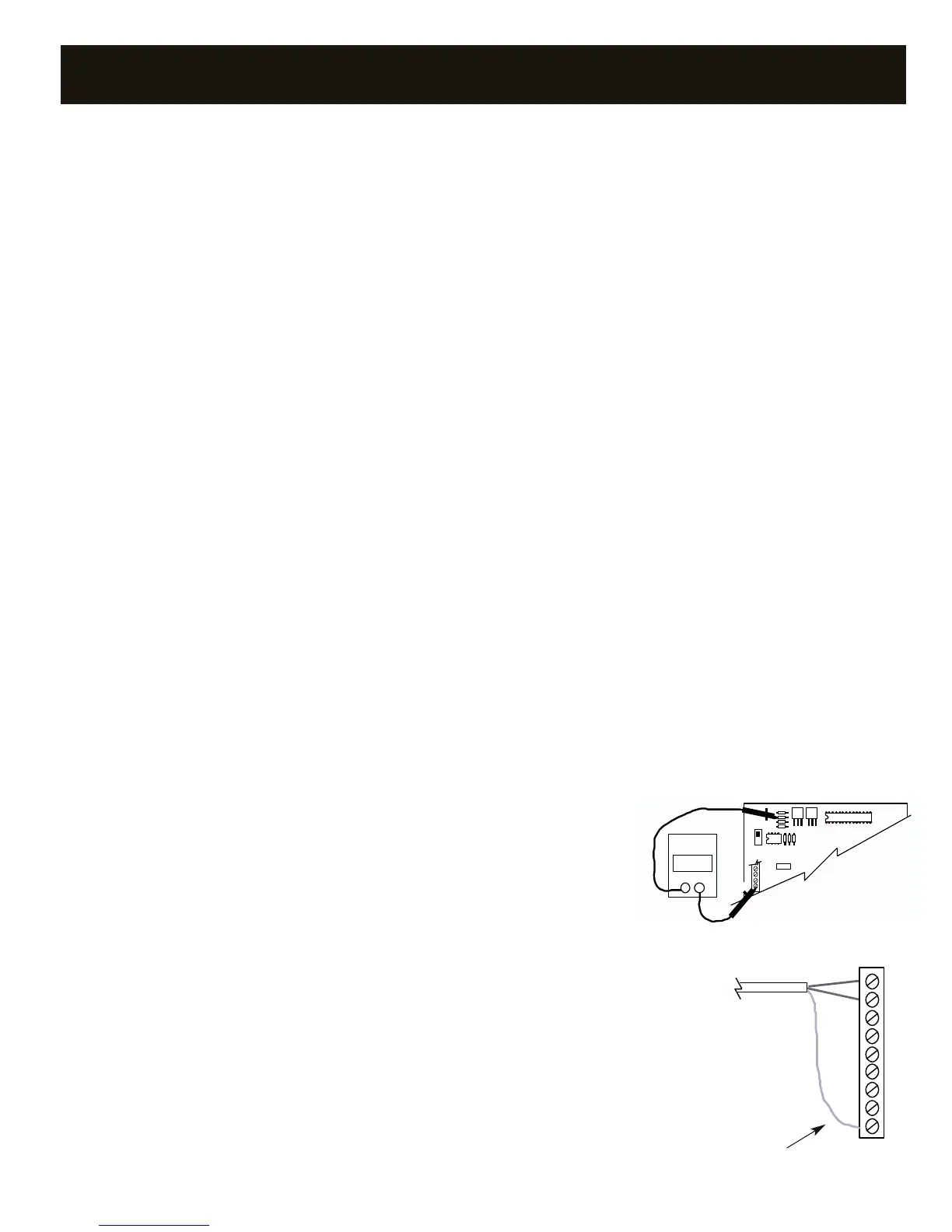

The Capacity Controller comes factory calibrated. However, if field calibration is ever necessary, perform the following:

1. Use a digital, DC voltmeter with 3 digits to the right of the decimal accuracy.

2. On the System Controller, place - probe of voltmeter to C terminal and + probe to left side of sec-

ond resistor from top (R10) as shown in adjacent diagram.

3. Measured voltage should read 2.718 VDC. If the voltage is incorrect, slowly adjust poten-

tiometer R72 until 2.718 VDC is obtained.

4. The LAS is now calibrated.

C

R72

DC

Voltmeter

2.718

+

–

STAGING AND CAPACITY CONTROL

COOLING OPERATION – DTGE4-2 AND DTHP4-2

HEAT OPERATION – GAS/ELECTRIC DTGE4-2

HEAT OPERATION – HEAT PUMP DTHP4-2

CAPACITY CONTROLLER – CALIBRATION

CAPACITY CONTROLLER – LAS INSTALLATION

11

SHIELD

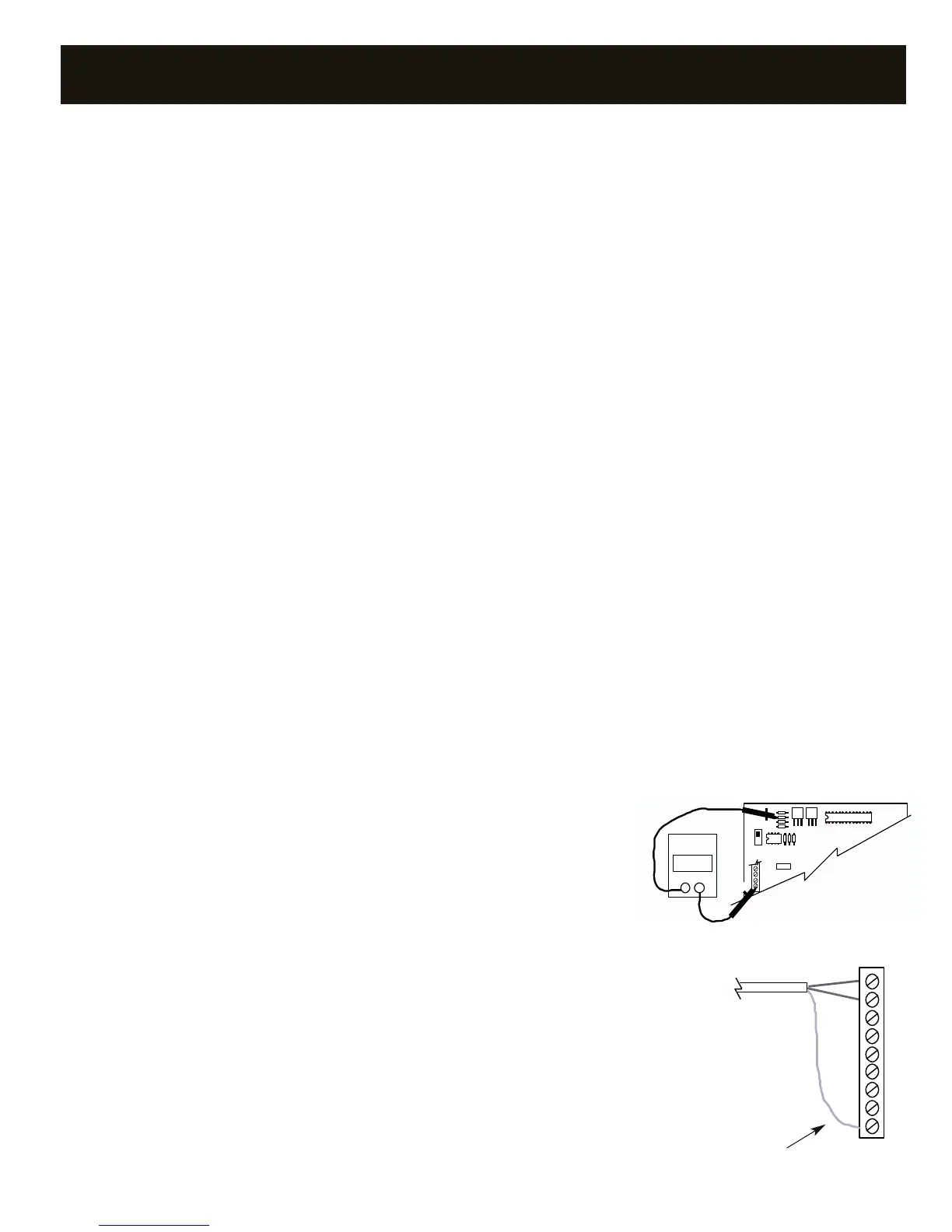

A. Cut or drill a hole in selected location large enough to fit sensor through.

B. Select location to install the LAS. For gas/electric HVAC systems, sensor must be in leaving air duct, preferably as

far from the coil/heat exchanger as possible but not past the bypass tap. For heat pumps, locate LAS downstream

from indoor coil but before auxiliary heat strips.

C. Place sensor through hole made in duct and mount Capacity Controller to duct with screws. Use grommet or tape

to protect sensor wire from sharp edges.

D. The cable between the LAS sensor and the controller must be installed separately from all 24 volt control and

power wiring. Using the shielded cable provided, connect the LAS between the + and – terminals of the controller

as shown. The shielded conductor is provided for installations with spark ignition or distances from controller to

LAS beyond 10’. 18/2 thermostat wire may be used in most applications.

Terminate the shield at the controller end only on the “C” terminal of the equipment terminal block.

Important: The shield at the LAS end of the wire must not be grounded, or attached to any other terminal.

The shield should be cut and taped off at the LAS end to prevent grounding.

Loading...

Loading...