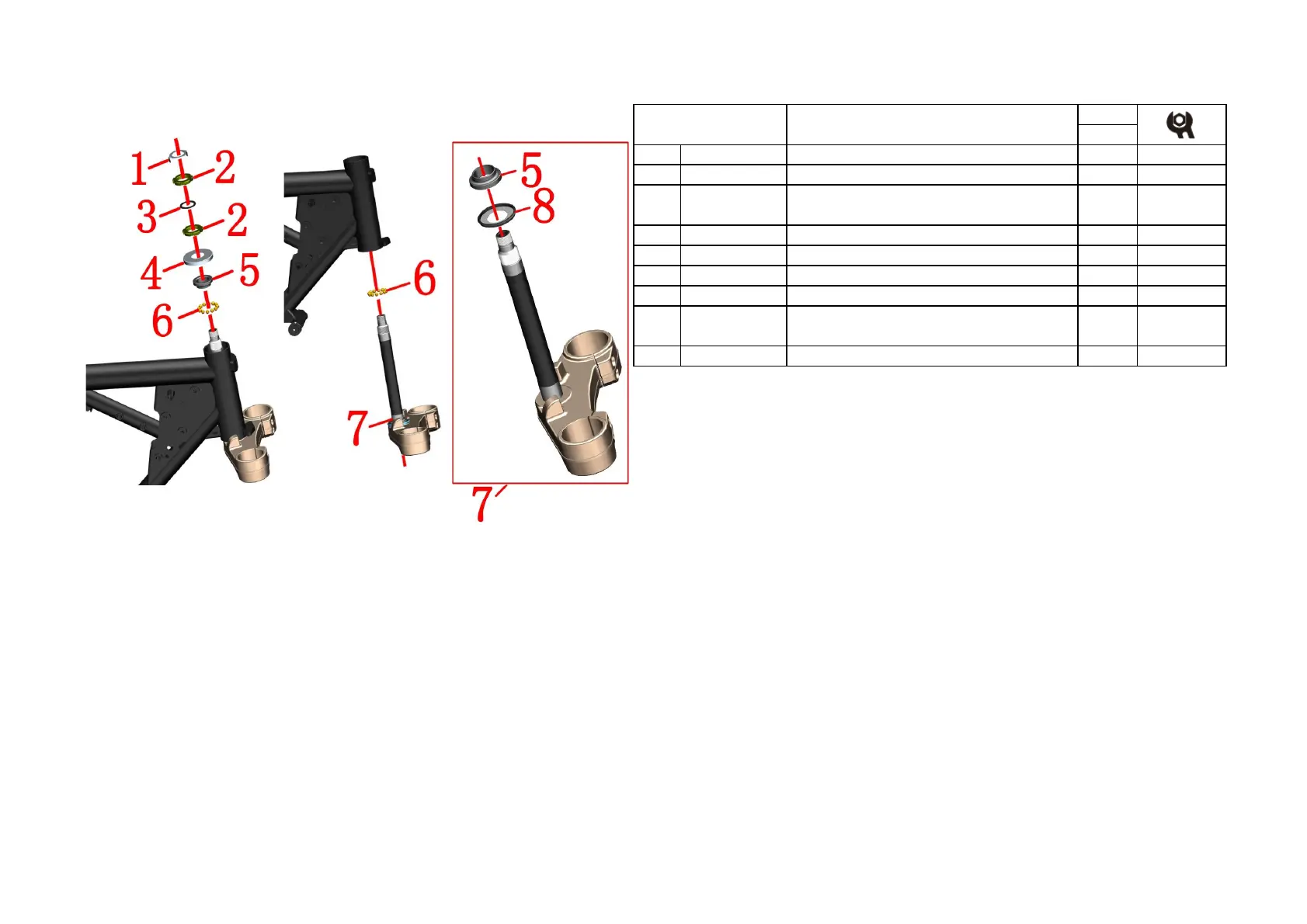

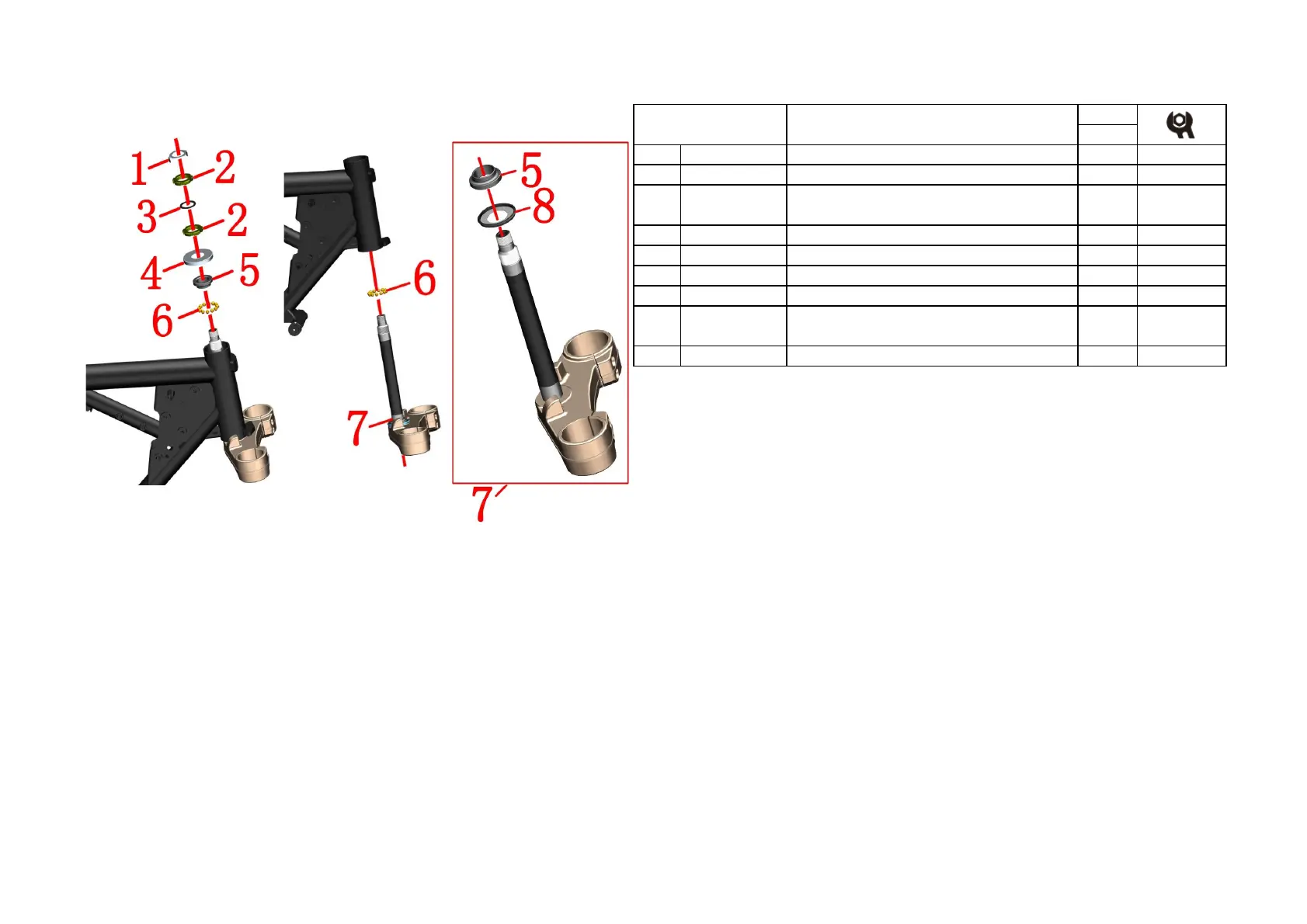

1-FRAME&ELECTRONIC COMPONENT

12

CHK

ADJ

NO. PART NO.

1 1134100-007000 ZT250-S Adjusting nut locking washer 1

3 1244100-015000 ZT250-S Adjusting nut rubber pad 1

4

1224100-005000 Steering stem dust cap (Up) 1

5

1130900-024000 Upper bead top 1

6

1130900-022000 Upper connect iron ball 2

8

1224100-006000 steering stem dust cap(down) 1

【

】

CAUTION:

●Remove the head part component, handlebarcomponent and front shock absorber component first.

●Please pay attentin to fix the awaiting repair motorcycles during disassembly,prevent dumping by accident.

●Please check whether the steel beads of the conjoined body have abnormal phenomena such as partial

abrasion and rust.If YES, please buy the regular accessories on official website, if not, please be sure to grease

the old grease and repaint the lubricating grease on it.

●It must be to check whether the steel ball is available during reassembly.

●It

must be reasonable to adjust the steering, too loose will cause the locomotive to brake slightly, and the

locomotive will shake slightly, too tight can lead to inflexibility, resulting in safety hazards.

●If you have the ability and the right tool, you can change the shaft ring ⑸ and the dustproof cover ⑻.During

the replacement process, pay attention to the protection of the lower connected plate. After replacement, it must be

to check the parallelism of the column and the damping hole, the vertical degree of the vertical column and the

lower connected plate.

●【1】the down connected plate (selfmade/with blowout patch) component⑺, has been contains the Steering

column down dustproof cover⑻.

2

●Dissembly

Remove the lock washer⑴.

Remove the top adjusting nut ⑵ by using a hook wrench tools.

Remove the rubber pad ⑶.

With one hand to hold down the down connected plate assembly ⑺, the other hand use a special four-

jaw set or hook wrench to remove the adjusting nut⑵.

Remove the upper dustproof cover⑷.

Remove the down connected plate component⑺.

Remove the axletee ring ⑸ of the upper riser and the steel ball⑹.

Remove the down connected plate component⑺.

Remove the steel ball of the down connected plate component⑺.

●Assemble

When reassembling, the conjoined steel beads should be painted lubricating grease,attention to the

dosage.

The torque of rating nut which closes to upper dustproof cover is required to about 14N.m.so as to be

able to rotate out of nimbleness.

The top adjusting nut only needs to rotate to the bottom of the nut groove alignment, not too tight to

prevent the rubber pad ⑶ from deformation too larg.

1

2

Fig.6 FRAME&ELECTRONIC

COMPONENT

Directional column component

7 1134100-015000

ZT250-S lower connection borad(self made/with ball

head) assembly

1251300-046093

Direction column adjusting screw nut M24X1

(environmental color zinc)

Loading...

Loading...