起

重

机

说

明

Assembly and

Dismantling

Operator’s Manual for Crawler Crane

5-15

e) Use wo

oden plates or steel plates to underlay all support plates.

Before operating the support cylinders and crawler carrier bolting cylinders, turn on

“undercarriage auxiliary control switch” in the auxiliary remote control box (see Section

4.5.7), and then operate the undercarriage control levers.

Each support cylinders and crawler carrier bolting cylinders can not only be controlled

independently but also operated simultaneously.

Select a support cylinder to be operated by the undercarriage control lever, and then

extend the support cylinder by operating the cylinder telescoping control lever.

Note: in the assembling process, the maximum force the support cylinder can bear is 29 t.

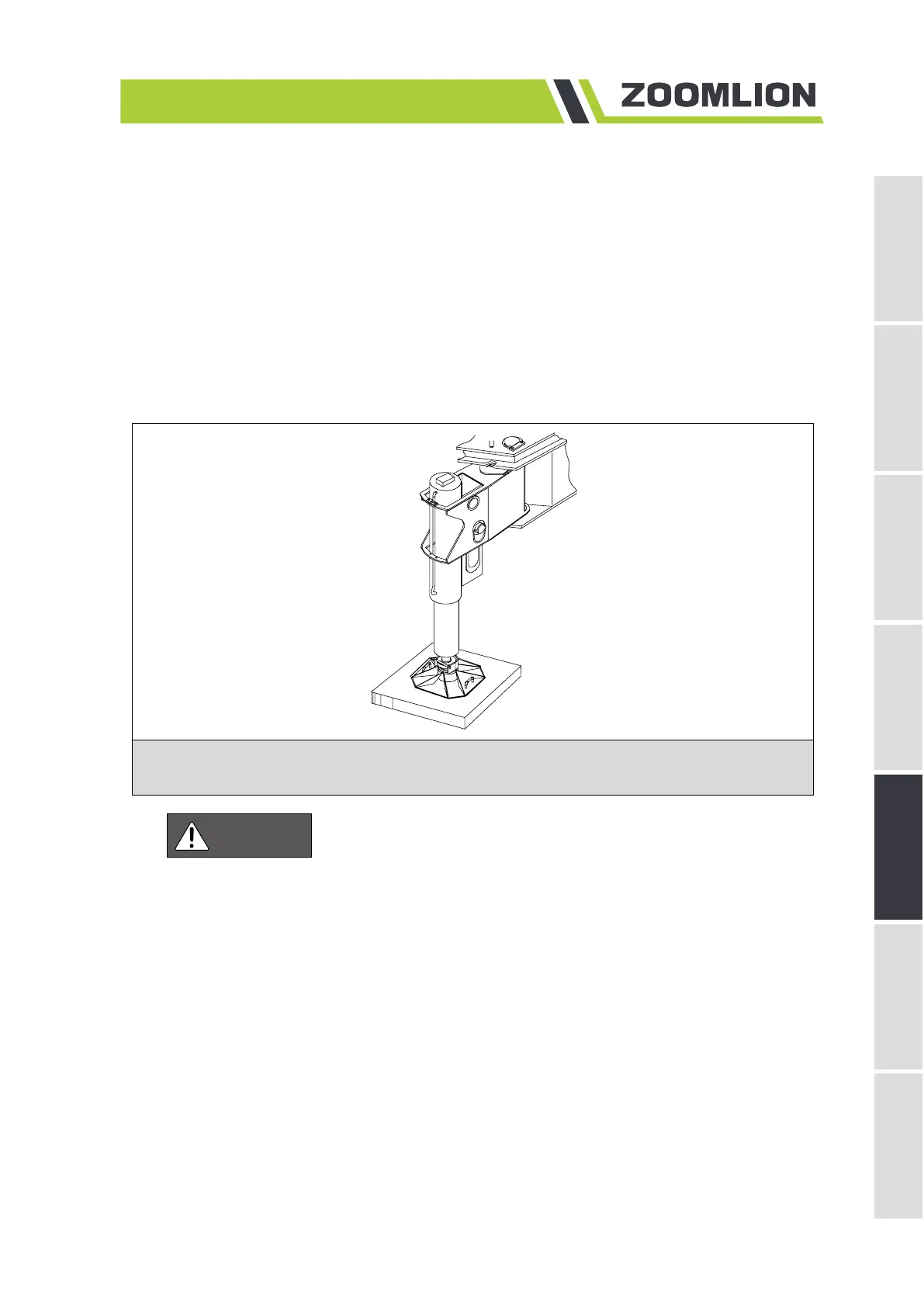

Figure 5-12 Support plate

(1

) In no circumstance, can the extending of support cylinders be carried out by one

person. At least two assistants are available to support the basic machine. One

assistant operates the control levers while another assistant watches the position

of support cylinders and see whether the crawler carrier bolting cylinder is

extended to specified position.

(2) When the support cylinders are operated, the engine should run at low-middle

speed (about 1000 – 1500 rpm).

(3) The support cylinders should be extended on firm and even ground. During

operation, pay attention to the level state of basic machine.

CAUTION

Loading...

Loading...