28 29

3

Spray Equipment Warranty and Limited Remedy

3M™ warrants to the original purchaser that, when used in accordance with 3M’s written

instructions, 3M spray equipment will be free of defects in materials and manufacture for one

year from the date of purchase. This warranty does not apply to damage or malfunction caused

by normal wear, failure to maintain, or by any abuse, accident, tampering, alteration, or misuse of

the spray equipment.

To make a claim under the warranty, you must fi rst contact the 3M Service Center at

1-877-MMM-CARS to receive a return authorization number. Spray equipment must be returned,

freight prepaid by the purchaser, to the service location address given by the 3M Service Center.

Upon validation of the warranty claim, 3M will replace or repair the spray equipment, at 3M’s

option, and return it to the purchaser at 3M’s expense, including parts, labor and return shipping

charges. If it is determined that the claim is not covered by the warranty, the purchaser will be

given the option to have the spray equipment repaired outside of the warranty. An estimate of

parts and labor will be provided by 3M and must be approved by the purchaser in advance.

Except as written above, 3M MAKES NO OTHER EXPRESS OR IMPLIED WARRANTIES OR

CONDITIONS, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. The purchaser is responsible for

determining whether the 3M spray equipment is fi t for any particular purpose intended.

Limitation of Liability: The remedies set forth above are exclusive. Except where prohibited

by law, 3M and any seller of the spray equipment will not be liable for any loss or damage

arising from or related to the use or inability to use this product, whether direct, indirect, special,

incidental or consequential, regardless of the legal theory or basis of liability asserted.

Note: Invoice is required for return authorization number and to determine warranty

eligibility.

Contact Information

TO PLACE AN ORDER, contact your 3M Sales Representative or Distributor,

or call this number:

1-877-MMM-CARS

(1-877-666-2277)

www.3M.com

All written and visual data contained in this document refl ects the latest

product information available at the time of publication.

3M reserves the right to make changes at any time without notice.

PRINTED IN U.S.A. ©3M 2009. All rights reserved.

3M, Accuspray and PPS are trademarks of 3M Company.

Tefl on® and Delrin® are registered trademarks of E.I. du Pont de Nemours and Company.

Revision A 34-8703-7205-8

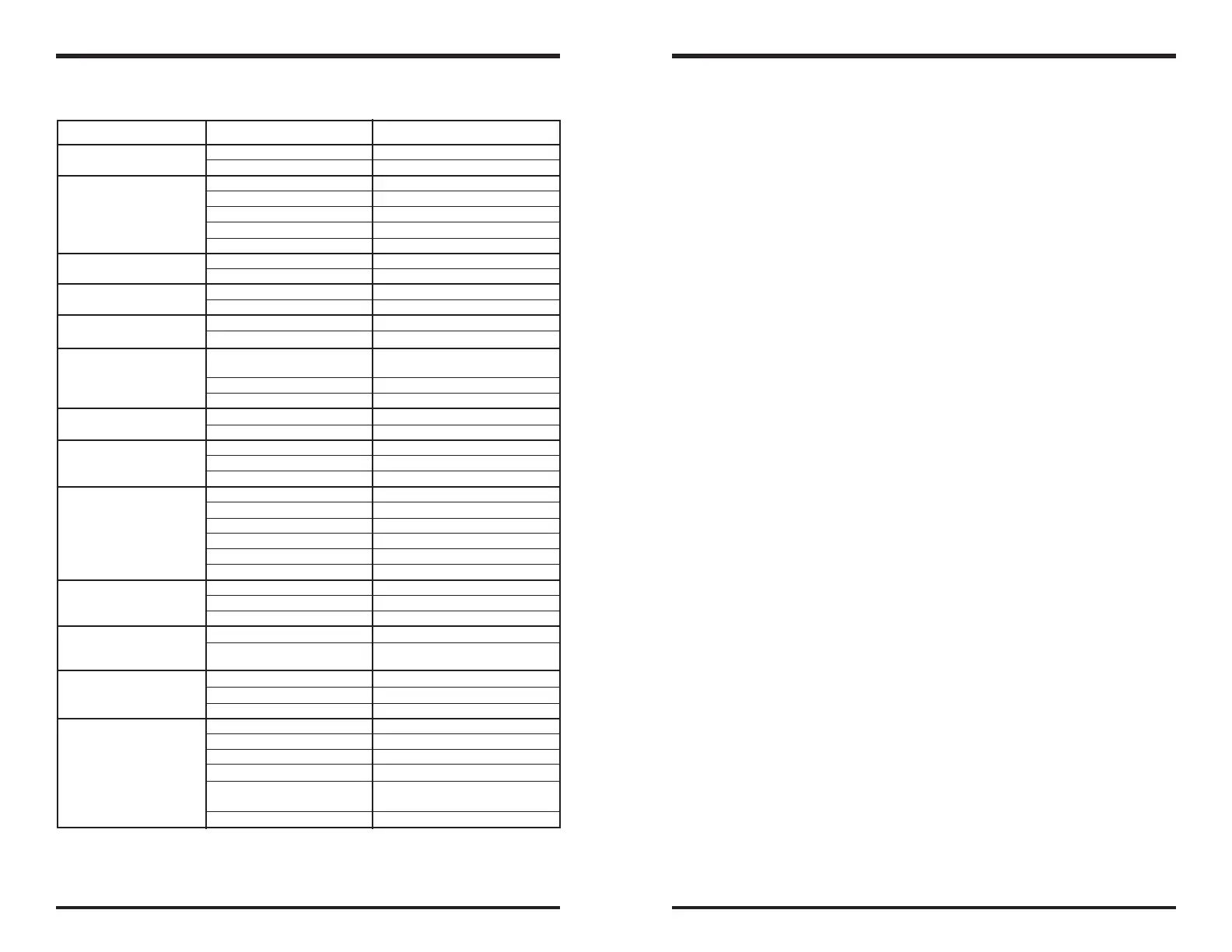

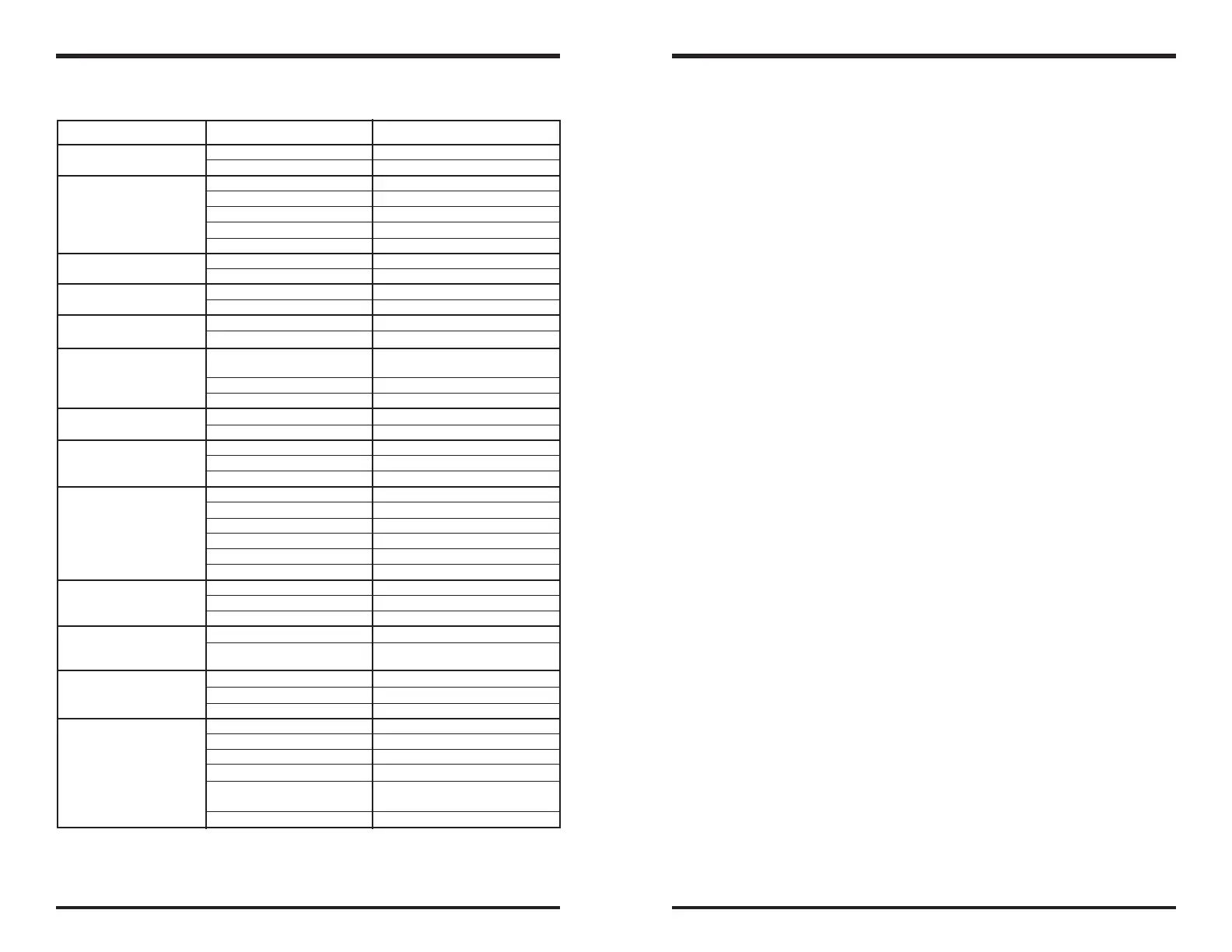

Problem Cause Remedy

Air cap or nozzle clogged Clean with appropriate solvent

Bent fl uid needle Replace fl uid needle

Moisture on surface Clean surface

Wrong solvent Check solvent

Blistering Coats not compatible Check material compatibility

Insuffi cient dry time Longer dry time

Surface too cold Warm surface

Air contamination Add air fi ltration

Silicone contamination Clean surface with solvent

Too much fl uid pressure Reduce fl uid pressure

Not enough atomizing pressure Increase atomizing pressure

Worn or loose packing Tighten or replace

Low fl uid in cup or pot Add fl uid

Restriction in fl uid line Use 3/8” fl uid hose

Blocked hose Flush or replace hose

Fluid nozzle too small Use larger needle/nozzle

Low fl uid pressure Increase fl uid pressure

Dirt or dust on surface Tack wipe before spray

Material is contaminated Change or strain

Coating too thin Use less thinner

Mottled Looking Surface Coats too wet Use less thinner

Improper spray technique Hold gun perpendicular to work

Clogged fl uid nozzle Clean fl uid nozzle

Loss of air pressure Check cup gasket

Loss of fl uid pressure Out of paint

Clogged air passage Clean with solvent

Restriction in mat’l hose Flush with solvent

Clogged check valve Replace check valve

Paint drying too fast Use proper solvent

Gun too far from target 6-8 inches is ideal

Viscosity too high Reduce with solvent

Gun too far from target 6-8 inches is ideal

Too much atomizing air

for coating being sprayed

Trapped solvent Apply lighter coats

Pin-Holing, Solvent Pops Improper solvent Check coating manufacturer

System contaminated Clean all parts

Wrong needle size Replace

Damaged-worn needle Replace

Loose fl uid nozzle Tighten or replace

Worn/loose packing nut Tighten or replace

Packing too tight. Broken or missing

needle spring. Dried paint on needle

.

Tilted gun Do not tilt while spraying

Troubleshooting

Bad Spray Pattern

No Paint Flow

Intermittent Pulsating Spray

Insuffi cient Fluid Flow,

Pressure Feed

Heavy Middle Pattern

Coarse or Lumpy Surface

Fish Eyes

Orange Peel

Overspray is Excessive

Paint Leak

Needle not closing

Reduce atomizing air

Loading...

Loading...