31

Special Set-Up Procedure (Continued)

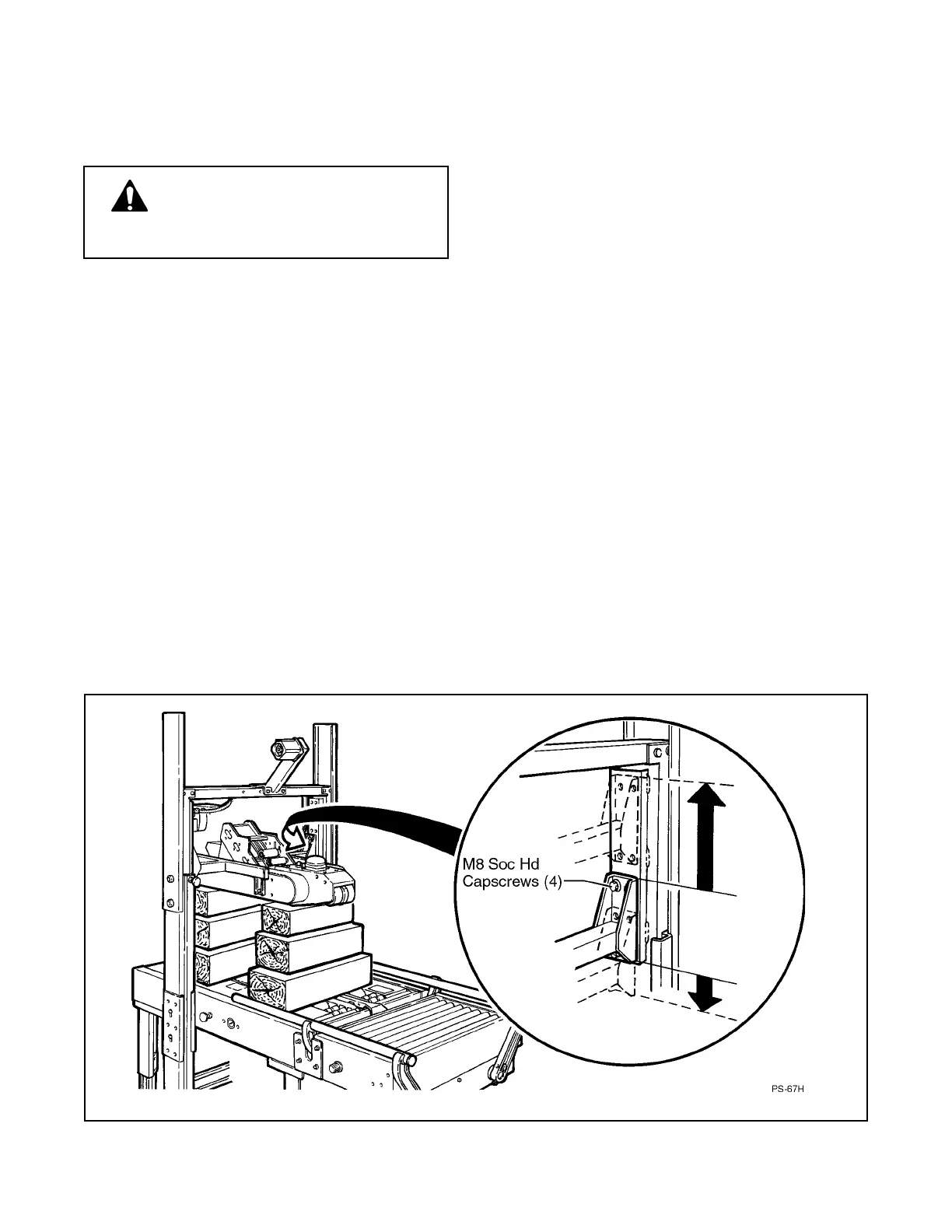

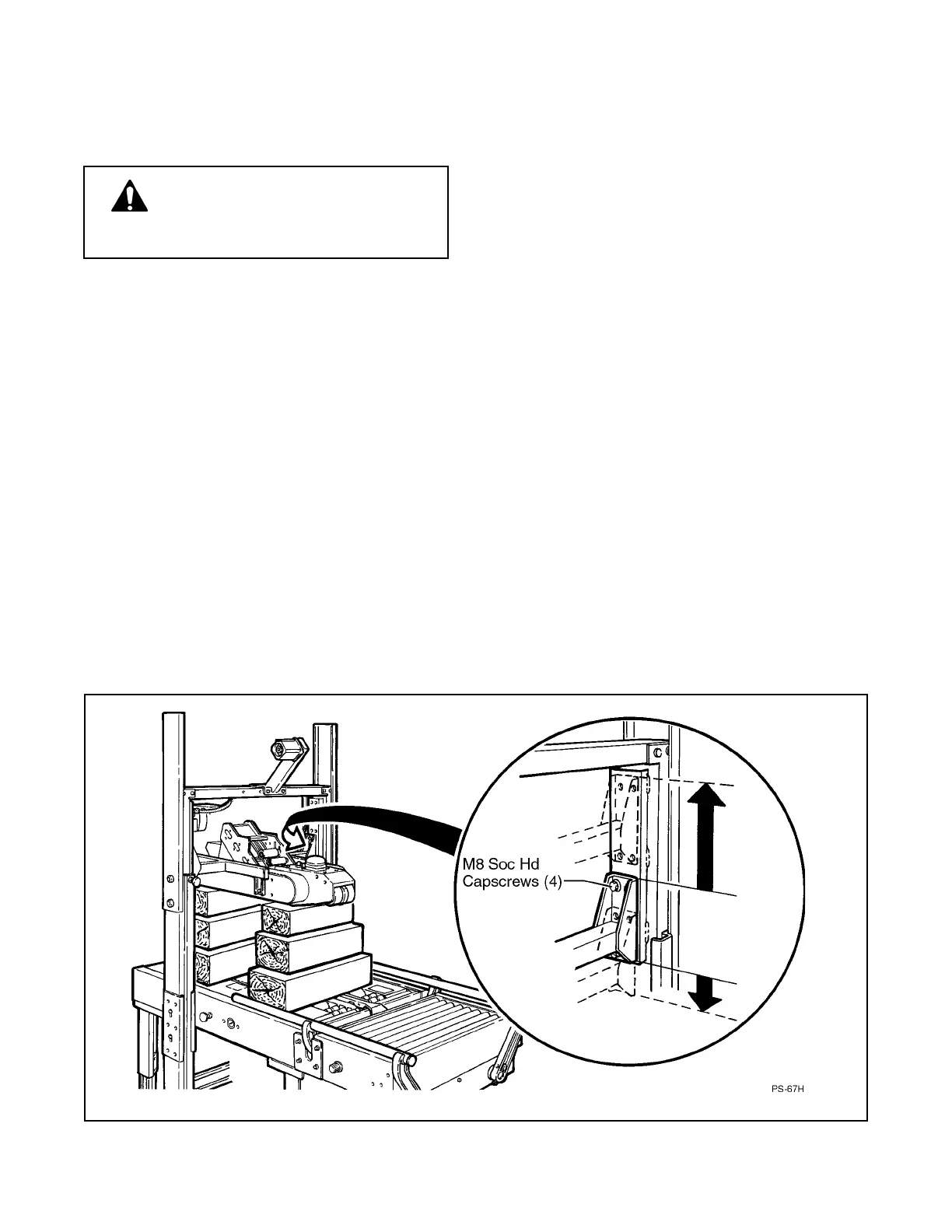

Upper Taping Head Frame Re-positioning

Figure 5-3

Figure 5-3 Upper Taping Head Frame, Re-Positioning

WARNING It is recommended that

no less than two people assist on this

set-up or severe injury or equipment

damage could result.

1. Raise and latch the upper taping head frame in

its full "Up" position.

2. Place solid blocks (minimum 305 mm [12

inches] high) beneath upper frame in front of

upper taping head applying roller and behind

taping head buffing roller. Important blocks

must be the same height in order to keep

drive belts parallel with machine bed.

3. Unlatch upper frame and allow it to come to rest

on blocks.

4. Turn off and disconnect air supply to machine.

5. Remove the four M8 socket head capscrews with

6 mm hex key wrench from each side of the

upper frame crossbar.

6. Move inner column assembly up/down until the

desired hole location is achieved. Note: When

adjusting frame to lowest position on

columns (small boxes), the four mounting

holes ABOVE the upper frame crossbar are

used.

7. Install four M8 socket head capscrews on each

side of upper frame crossbar. Do not tighten.

8. Check to be sure upper drive belts are parallel to

machine bed. Measure from machine bed to

upper belts, front and rear and adjust upper

frame as necessary to make it parallel with

machine bed. Tighten belts installed in step 8.

9. Connect/turn on air supply to machine and raise

upper frame, latch in place, remove blocks and

unlatch upper frame allowing it to return to its

rest position

Loading...

Loading...