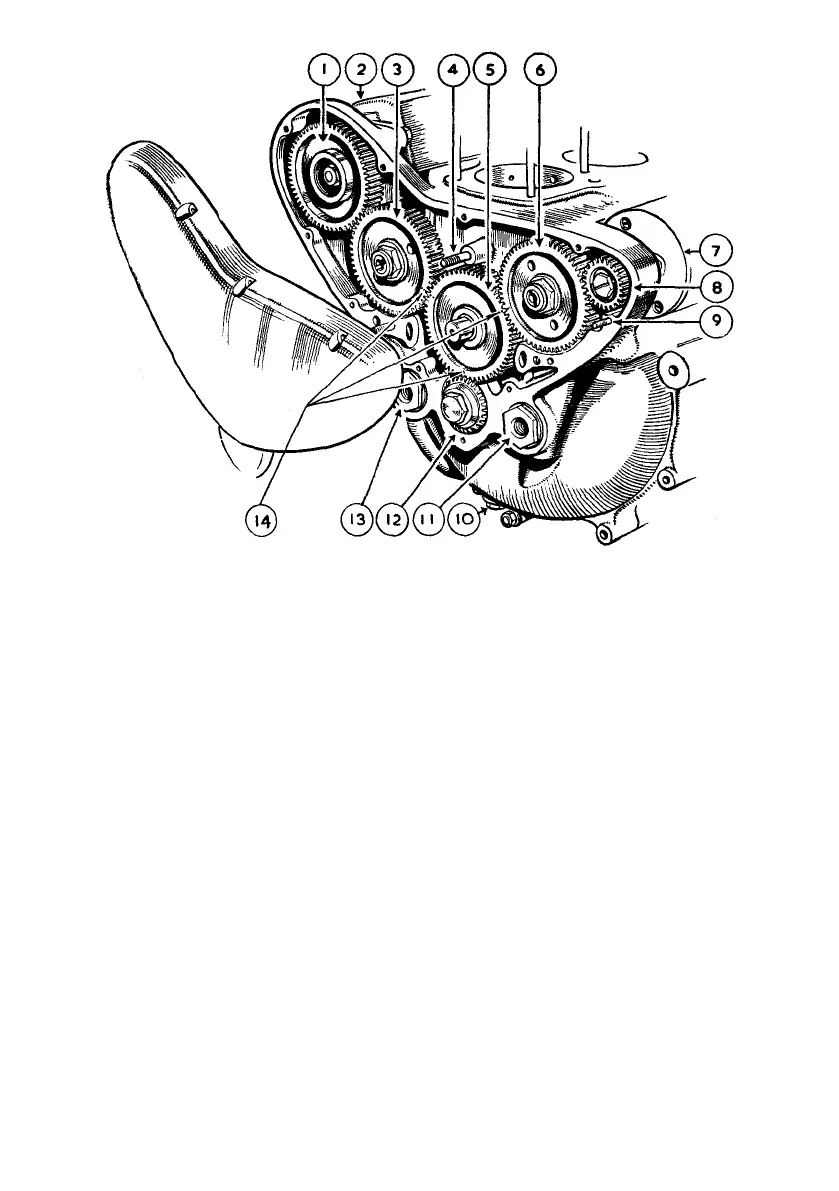

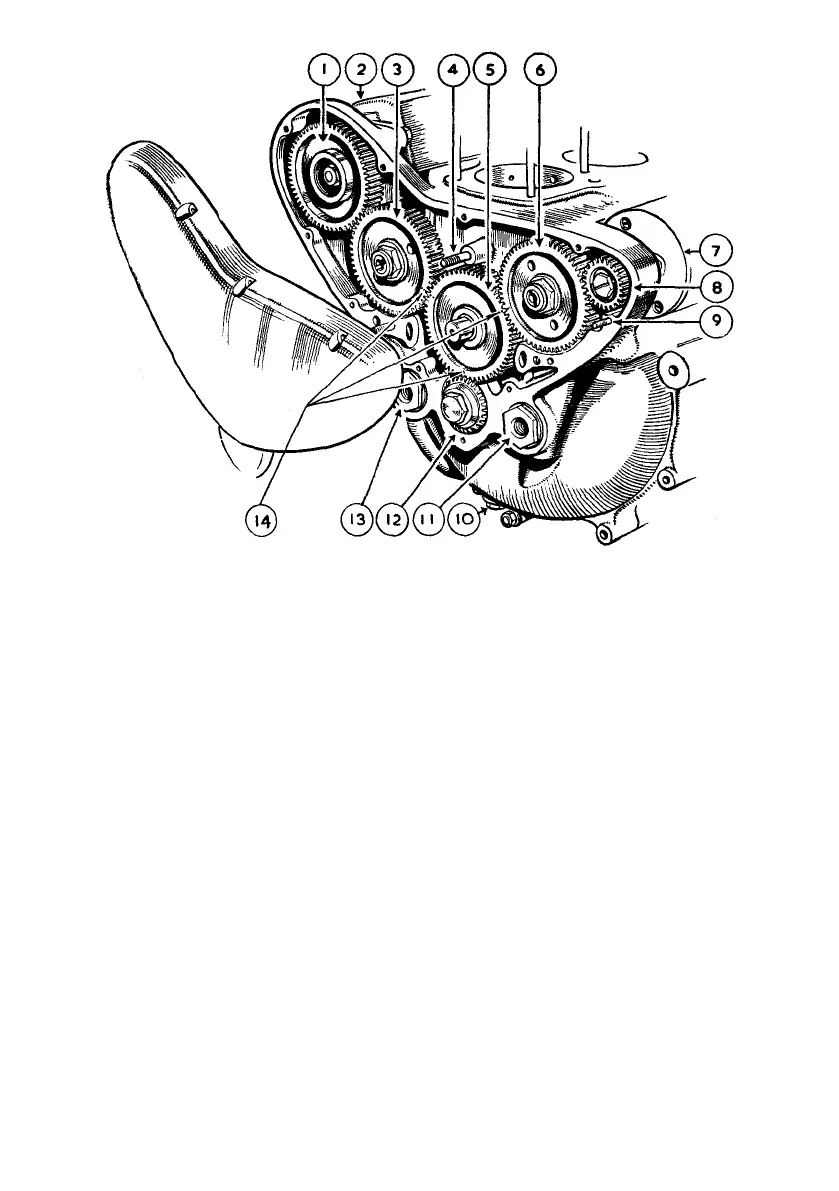

Illustration 21

Valve timing gear

The gears on the two camshafts (secured by nuts having left-hand threads) have to be

mechanically withdrawn and each has two holes drilled and threaded to accommodate

the two bolts of a bridge type extractor (part number 015374) which has a central bolt

threaded in the bridge. The two outside bolts are screwed into the holes in the gears

whereupon application of the centre bolt being screwed into the bridge bears on the

end of the shaft thereby causing the gear to be withdrawn.

The gear on the dynamo needs no extractor because the dynamo, complete with gear

assembled, is easily and quickly removed from the engine and the subsequent removal

of the gear from the dynamo shaft is a simple workshop operation.

ALTERNATOR TWINS

To remove distributor pinion, spring outwards the circlip, take out the parallel pin

passing through the pinion and distributor shaft—the pinion can then be removed.

1

2

3

4

5

6

7

8

GEAR WHEEL ON MAGNETO ARMATURE

SHAFT.

MAGNETO.

GEAR WHEEL ON INLET CAMSHAFT.

ONE OF THE THREE STUDS RETAINING

THE OIL PUMPS ASSEMBLY.

INTERMEDIATE (OR IDLE) GEAR.

GEAR WHEEL ON EXHAUST CAMSHAFT.

DYNAMO.

GEAR WHEEL ON DYNAMO ARMATURE

SHAFT.

9

10

11

12

13

14

STUD, IN DYNAMO BODY A N D PASSING

THROUGH CRANKCASE AN D TIMING

GEAR COVER.

CRANKCASE DRAIN PLUG.

ADAPTOR TO ACCOMMODATE OIL FEED

PIPE BANJO PIN.

TIMING PINION ON CRANKSHAFT.

ADAPTOR TO ACCOMMODATE OIL

RETURN PIPE BANJO PIN.

MARKS TO SET TIMING.

See page 96 for particulars of special timing disc graduated in degrees.

Loading...

Loading...