12

the temperature is less than the operating setpoint minus the

differential temperature and the thermostat input is closed then

a call for heat is established and the system shifts to the run

mode (green “Running” LED turns on).

5. The heating sequence begins by applying power to the pump.

6. After a few seconds the blower is turned on for 30-second

pre-purge period of combustion chamber.

7. The igniter is turned on.

8. After the igniter has reached a minimum of 2.8 amps, the gas

valveisenergizedtoallowgasowtoburner.

9. After an additional one second, the system checks the status

oftheamethroughtheamerod(sensor).Iftheameisnot

veriedwithin4seconds,thegasvalveisimmediatelyshut

off followed by 15-second inter-purge period, then the system

returns to step 7, if the “Trial for Ignition” dipswitch is set for

three (3) tries. If the dipswitch is set for one (1) trial, the system

will declare an error and boiler will require resetting the control.

10. Theboilerwillremainrunninguntilthesetpointissatised.

Once satised, the blower will continue for 15-second post

purge period.

11. Oncesetpointhashavebeensatised,theboilerpumpwill

continue to run for the programmed post-circulate cycle.

12. The control now enters the idle state as displayed by the

“Standby” LED. The control will continue to monitor heat

demand and state of other system devices. Upon a drop of

water temperature below the set parameters, the control will

return to step 5 and repeat the entire operating cycle. Note:

Any fault detection, during standby or running modes, will halt

the heating sequence and shift the system to the service mode

where the detected fault will be displayed.

NOTE: In standby and running modes the system constantly

monitors the signals and the internal operation for faults. Any

detected fault will halt the heating sequence and shift the system

to the service mode, where the detected fault will be displayed.

TEMPERATURE SETPOINTS (SYSTEM CONTROL ALGORITHM)

The boiler has a hysteresis type control, which means that it will

begin heating the water when the temperature sensed by the

control probe (inlet or tank) falls below the operating setpoint minus

the differential setpoint. It will stop heating the water when the

temperature rises to the operating setpoint.

UIM OPERATING PROCEDURES

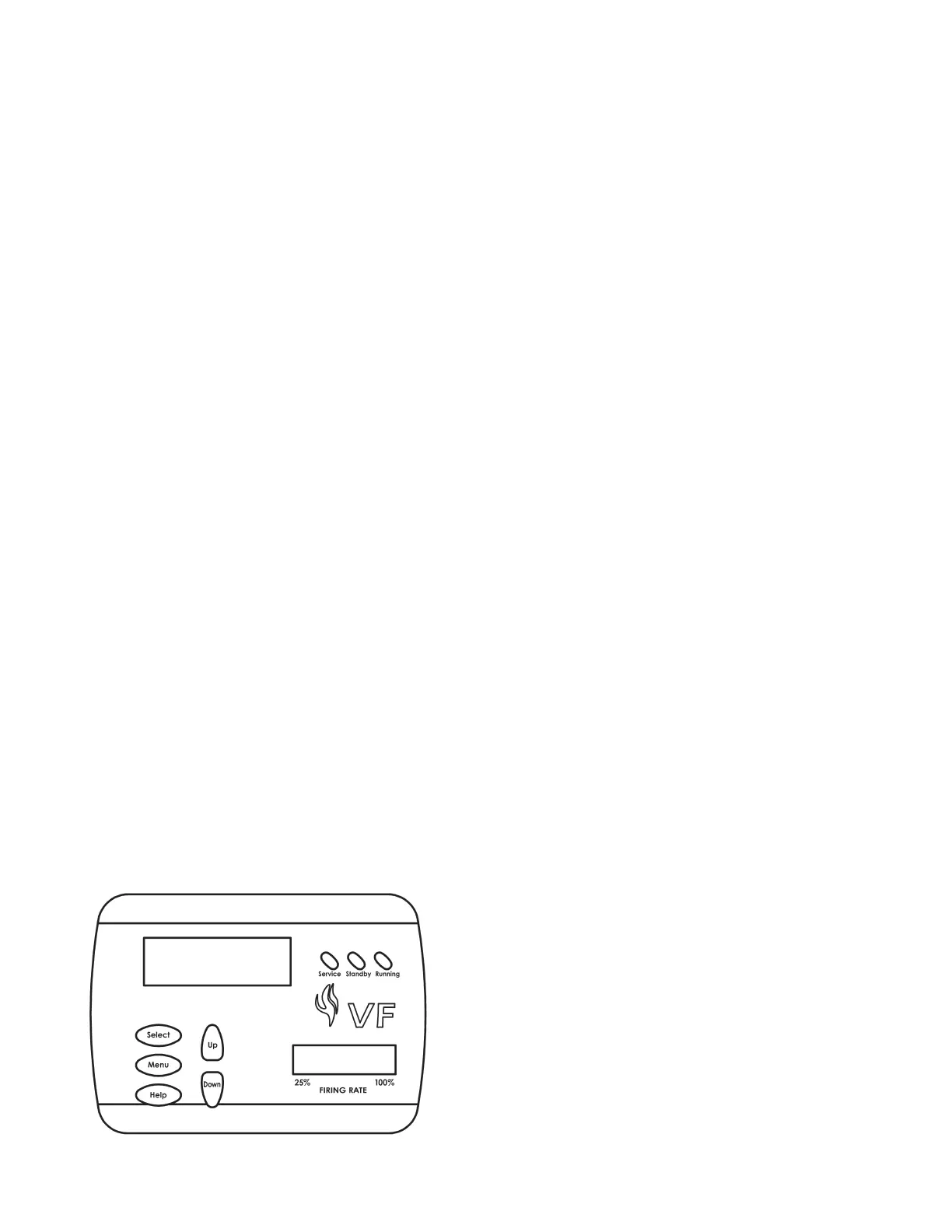

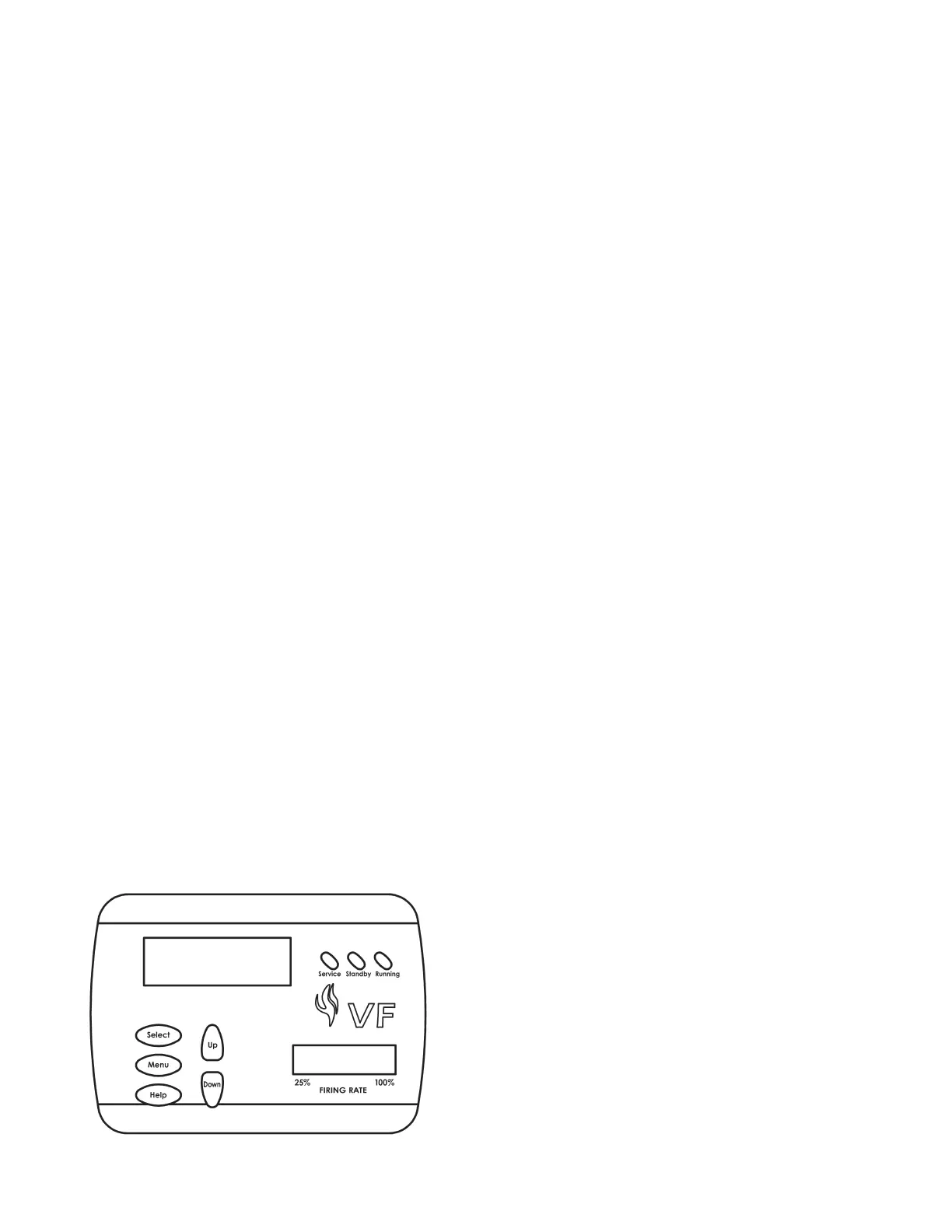

FIGURE 2. - UIM, USER INTERFACE MODULE

The UIM receives commands from the user and displays operational

information to the user via an LCD (liquid crystal display) up to eleven

LED’s,andvetouchswitches.TheLCDprovidesinformationto

the user by the use of 10 menu-activated screens. Within each of

the screens, helpful information can be displayed by pressing the

“Help” button. The LED’s visually inform the user about the mode

the system is in. The touch switches allow the user to control the

operation of the system. The operation of these parts is described

in the following section:

UIM Screens:

On all screens a double vertical bar appears on the right side of

the display each time a key is touched to indicate that a key has

been activated. On several screens an indicator “>” appears on

the left side of the display to indicate the active line. The “Up/

Down” keys are used to move the indicator to the desired line and

the “Select” key is pressed to select the line. Also, on most of the

screens, up/down arrows appear on the right side of the screen

to indicate that there is additional lines either above or below the

displayed four lines.

• Menu Screen:

Displayed when the user presses the “Menu” key. This screen

is the selection point for the other 9 screens.

• Temperature Screen:

Displays the sensed temperatures of the Outlet, Inlet, and

Tank probes. Also displayed is the calculated Delta T (Outlet

minus Inlet) for the system. Shorted (“Short”) and disconnected

(“----”) probes are also displayed.

• System Status Screen:

This screen is used to view the status of switch inputs and output

states. An asterisk (*) is displayed next to the label when the

status is “True” (the description is fullled). For example, if

waterisowing,ordetectedbytheowsensor,thenan“*”will

appear in front of the Flow label (i.e. *Flow). Another example

would be the ECO switch. If the outlet temperature is too high

the display will show: *ECO.

The System monitors the inputs at these times:

• ECO,BlockedFlue,LowGas,HiLimit,andHiGas-atalltimes

for a fault condition.

• Tstat-atalltimesforopen/closedconditions.

• Flow - for an on condition when the pump is on (no check for off

state)

• BlowerProver-whentheBlowerison.

• IgniterCurrent-foranonconditionapproximately18seconds

after the Igniter is turned on until the igniter is turned off and an

off condition at all other times.

• Flame-foranonconditionapproximately5secondsafterthe

gas valve is turned on until the valve is turned off and at all other

times for an off condition.

Control Status Screen:

Displays the status that the MCB micros are in. The MCB has

5 possible states and the FCB have 9. The normal MCB states

sequence is to move from Idle to Pre-Circulate when a call for

heatisinitiated.OnceheathasbeensatisedortheThermostat

is opened, the sequence moves to Post-Circulate and then back to

Idle. If a fault occurs at any time, the process jumps out of sequence

and goes directly to the appropriate Hard or Soft Fault state.

Description of MCB control states:

• Idle:

The yellow “Standby” LED is turned on and the system

Loading...

Loading...