TRANSFORMER COMPONENTS

3

—

.

3. Installation

3.1 Comem eOLI

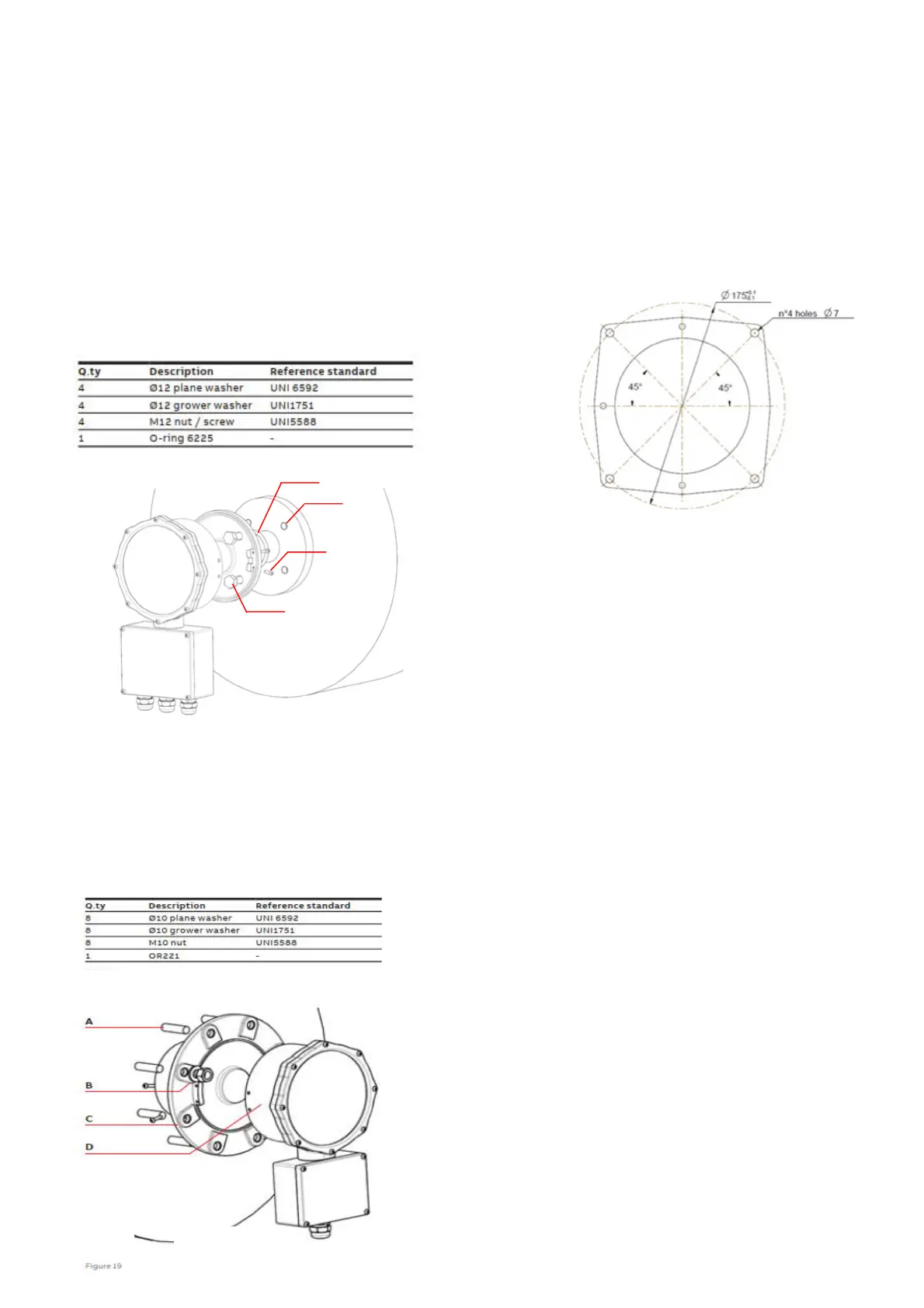

Insert the arm with float through the machined

hole on the conservator Place the o-ring on the

slot behind the gauge

(Fig.1/B) . Align the flange (Fig.1/C - stud length:

20±1 mm) with the threaded pins or holes

(Fig.1/A) (depending on the conservator flange

type). The gauge has to be assembled on the

flange using four screws M4x12 (Fig.1/D). The oil

level indicator flange has to be assembled using

the items showed in the table 1.

Table 1

Fig 1

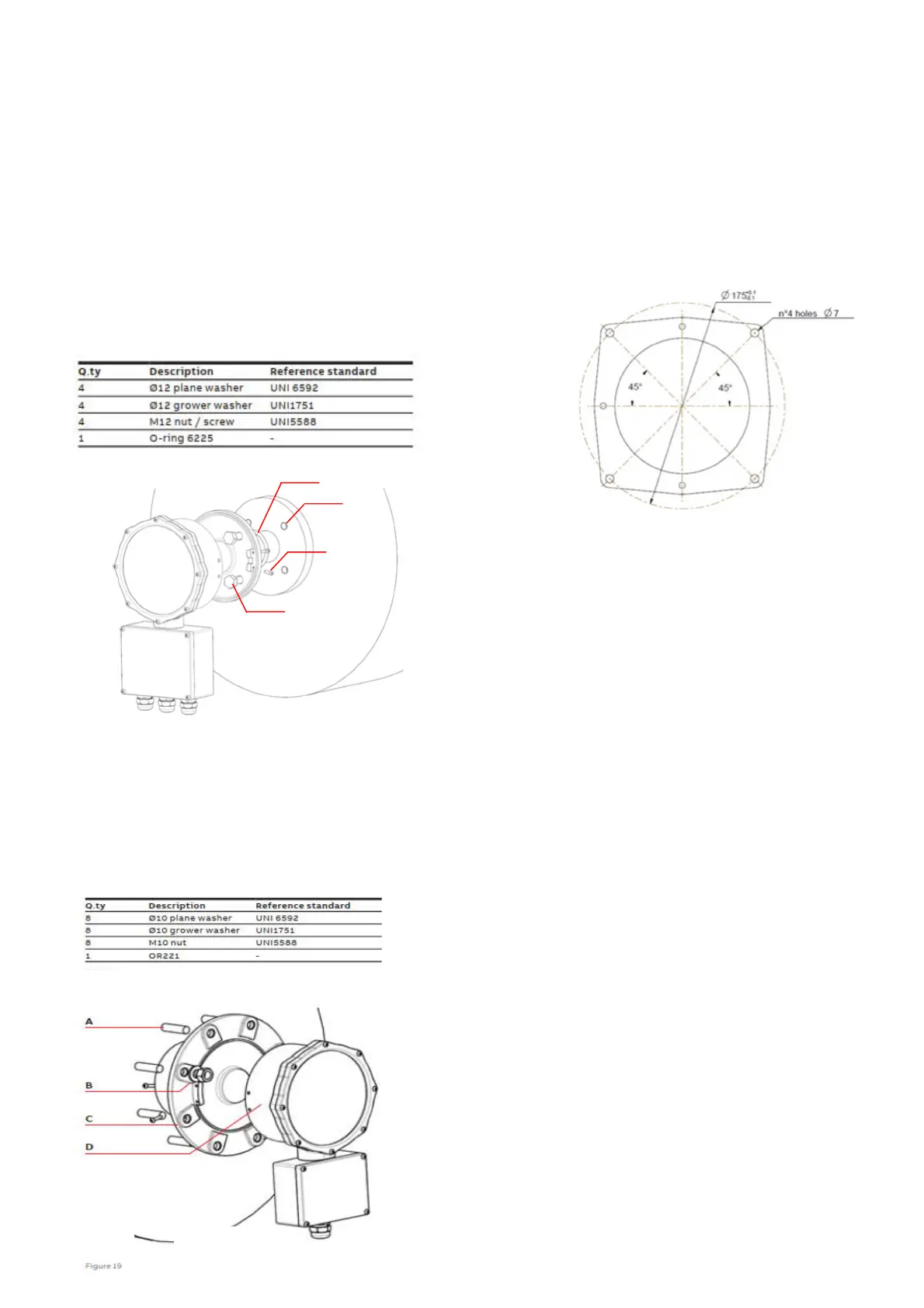

3.1 Comem eOLI22

Insert the arm with float through the machined

hole on the conservator. Place the o-ring in the

slot behind the flange (Fig.1/C). Insert the flange

on the threaded pins (Fig.1/A) of the conservator

flange and fix it with the items showed in the

table 2 (Fig.1/B). Fix the gauge on the flange

using 4 screws M4x12 (Fig.1/D).

3.3 Comem eViewer

Arrange the transformer with a dedicated place

following the scheme in the figure 3. The

connection can be done in two alternative way:

• threaded pin and nut M6

• screws M6

Fig.3

3.4 Modbus parameter

In order to implement a communication network

with eOLI/eOLI22 communicating in Modbus

RTU, the following communication parameters:

shall be considered:

-

Speed of data transmission (baud rate

): 9600

bits/s

-

Data bits (number of bits

): 8

-

Parity bit

: None

-

Stop bit

: 1

Fig.2

A

D

C

B

Table 2

Loading...

Loading...