The ABB Terra HP Generation 3 UL 175 kW Static DC system is an Electric Vehicle Supply Equipment (EVSE) designed for DC high-power charging of electric vehicles (EVs). It can be installed both indoors and outdoors. The system's electrical grid properties, ambient conditions, and EV compatibility must align with the technical data provided in the manual. The EVSE should only be used with manufacturer-approved accessories and in compliance with local regulations. It is explicitly stated that power cabinets from this EVSE should not be mixed with power cabinets from different EVSEs.

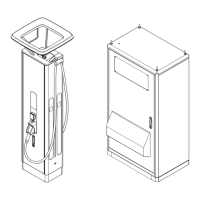

The EVSE consists of a distribution board, a power cabinet, and one or more charge posts. The power cabinet houses the DC output busbars, cable inlets, PE busbar, AC power connector, fuse block, X-10 and X-8 terminal blocks, a CAN2FIBER device, and relays. The DC output busbars are used to connect DC output power cables, while the cable inlets provide openings for cables. The PE busbar connects PE cables, and the AC power connector connects to the AC input power cable. The fuse block protects the machine from overcurrent and prevents short circuits in downstream components. The X-10 terminal block connects the AC auxiliary power cable, and the X-8 terminal block connects the interlock and DC guard cables. The CAN2FIBER device connects the optical CAN cable, and the relays control power sharing between two cabinets in dynamic DC versions.

The charge post, specifically the CP500 Generation 3, features an EV charge cable, an RFID reader and optional payment terminal, connector holders, a touchscreen, a door, a top light, side LED strips, a cable retraction system, an enclosure, air inlets and outlets, a type plate, an antenna, hoisting points, and plinth covers. Internally, the charge post includes a cooling unit to decrease the temperature of the charge cables, DC power busbars for connecting DC power cables, cable gland plates for cable entry, a PE busbar for the PE wire, a Q1 RCD (residual current circuit breaker) for AC auxiliary power connection/disconnection, X-10 and X-20 terminal blocks for AC auxiliary power and interlock/DC guard cables respectively, and a CAN2FIBER device for the optical CAN cable.

Important Technical Specifications:

- EVSE Type: Terra HP Generation 3, UL 175 kW Static DC system. The type plate code (T U V) indicates Model (HP for Terra high power), Part (CP500 for 500 A DC output or power cabinet), and EV charge cable connection (C for one CCS, CC for two CCS, CJ for one CCS and one CHAdeMO) or Peak output power (175 kW).

- Mass and Center of Gravity:

- Power cabinet: 1400 kg (3086.5 lbs). Center of gravity: X=587 mm (23.1 in), Y=407 mm (16.0 in), Z=1068 mm (42.1 in).

- Charge post: 250 kg (551.2 lbs). Center of gravity: X=353 mm (13.9 in), Y=244 mm (9.6 in), Z=1096 mm (43.2 in).

- Ambient Conditions:

- Operation temperature: -35 °C to +55 °C (-31 °F to +131 °F) (derating applies).

- Storage temperature: +5 °C to +40 °C (+41 °F to 104 °F), RH 5 to 85%.

- Environment: IP54, rainproof; IK10 (screen: IK08).

- Altitude: Maximum 2000 m (6562 ft) above sea level.

- Noise Level:

- Charge post (500 A continuous up to 35 °C): ≤ 60 dB(A) at 1 m (39.4 in).

- Maximum noise level of charge post: 68 dB(A) at 1 m (39.4 in).

- Power cabinet: ≤ 65 dB(A) at 1 m (39.4 in).

- Electrical Installation (North America):

- Upstream overcurrent protection device: Fuse (gG type) 300 A.

- Surge protection device: According to UL 1449.

- Input AC power connection: 480/277 3W + PE, wye Grounded system.

- Input voltage range: 480 VAC +/- 10% (50 Hz or 60 Hz).

- Nominal input current: 231 A at 480 V AC.

- Efficiency: ≥ 94% at ≥ 20% load.

- Maximum AC inrush current: 240 A for 20 ms at 480 VAC.

- DC Output Specifications:

- Output voltage range: 150-920 V DC.

- Maximum output current: 375 A DC (one power cabinet), 500 A DC (two power cabinets).

- Output power: 175 kW up to 40 °C (104 °F) (one power cabinet), 350 kW up to 40 °C (104 °F) (two power cabinets).

- DC output current: 500 A CCS (liquid cooled), 200 A CHAdeMO.

- Maximum I²t: <60 kA²s with a duration of 1.2 ms.

- Cable Specifications: Detailed specifications are provided for AC input, DC power, PE, AC auxiliary power, interlock/DC guard, optical CAN, and Ethernet cables, including number of cores, cross-section range, diameter, insulation, voltage rating, and strip length. For example, AC input cables are 4 cores, 177-240 mm², 450/750 VAC. DC power cables are DLO, Type W, 1 core, 125-300 mm², 1000 V. PE cables are 1 core, 35 mm², 600 V. Optical CAN cables are 2 fibre cores for installation, 2 as spares, OM3 (multimode). Ethernet cables are shielded, 4x2 twisted pairs, 600 VAC.

Usage Features:

- Charging Standards: Supports CCS and CHAdeMO charging methods.

- User Interface: Features a touchscreen for user interaction and an RFID reader for authentication.

- Cable Management: Includes a cable retraction system for convenient cable handling.

- Connectivity: Supports 4G LTE wireless network (Vodafone) via Charger Connect service or a wired Ethernet connection for internet access.

- Remote Monitoring: The Network Operating Center of ABB EV Infrastructure can perform remote checks on the EVSE's operation.

Maintenance Features:

- Access to Parts: The manual provides detailed procedures for opening the power cabinet and charge post doors, removing plinth covers, DC busbar covers, AC covers, and protection plates to access internal components for maintenance.

- Cable Installation: Instructions cover connecting various cables (PE, AC input, DC power, AC auxiliary power, interlock/DC guard, optical CAN, Ethernet) with specific torque requirements and cable lug/ferrule installation procedures.

- Foundation Preparation: Detailed guidance on preparing prefab concrete, metal, and custom foundations for both the power cabinet and charge post, including specifications for dimensions, cable conduits, and anchoring.

- Transport and Unpacking: Procedures for inspecting transport sensors, unpacking the EVSE, and safely transporting it to the installation site using forklift trucks or hoisting equipment, with warnings regarding mass, center of gravity, and potential damage.

- Safety Instructions: Emphasizes the importance of qualified personnel, personal protective equipment (protective clothing, safety gloves, safety shoes, safety glasses), earthing, and adherence to local rules and regulations. It also highlights general risks, hazardous voltage, risk of pinching/crushing, rotating parts, and hot surfaces.

- Cyber Security: Stresses the owner's responsibility to ensure a secure connection between the product and the network, implementing measures like firewalls, authentication, data encryption, and anti-virus programs.

- Waste Disposal: Provides instructions for discarding the EVSE or its parts in compliance with local rules and WEEE directives, emphasizing separate disposal of electrical and electronic equipment.