Installed in all Trip Units types the second SETUP mode display is

always the Short Time Pickup set point. The Short Time Pickup

funcƟon establishes the current at which a Ɵmed short Ɵme trip

is acƟvated (Ist) and is adjusted in funcƟon of the Long Time

Pickup seƫng Ir. The choices of pickup seƫngs are from 1.5 to

12.0 (1) Ɵmes the long Ɵme seƫng, xLT ( Ir) , in steps of 0.5 xLT

(Ir). see table 2.5. The ST pickup value (Ist) tolerance band is

-10% to +10% of the set point. An addiƟonal accuracy

degradaƟon of ±5% occurs when waveforms with signiĮcant

harmonic distorƟon are present.

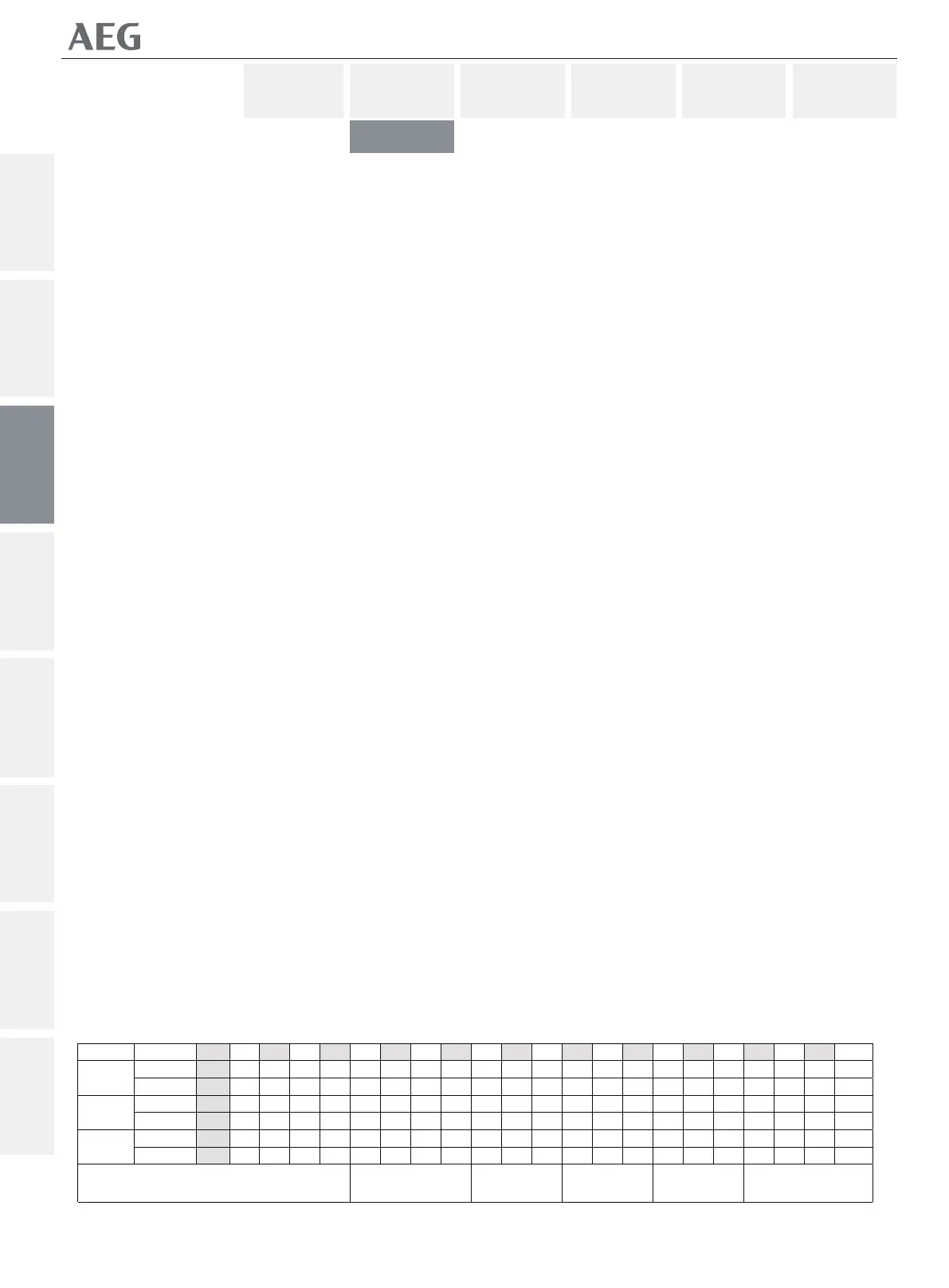

TheMpro type S and N trip unit types oīer 22 long Ɵme delay

bands that have a shape similar to that of the thermal element

of a thermal magneƟc circuit breaker.

The minimum and maximum delay Ɵmes and their IEC 947

classiĮcaƟon are indicated in table 2.3. The bands are depicted

as Time Current Diagram in appendix 6.1 of this ApplicaƟon

manual.

Installed in all Trip Units types the Įrst SETUP mode display is

always the Long Time Pickup setpoint. This set point establishes

the breaker's ampere raƟng Ir.

The 1st screen allows the user to deĮne up to 6 diīerent user

currents Ie that can be set as a fracƟon of 1, 0.98, 0.97, 0.96,0.45

or 0.4 x the breaker current raƟng In. These are indicated as a

current value on the screen

The deĮnite current seƫng Ir is set on the 2nd LT seƫng screen

as a fracƟon of the user current value Ie. (xLT = LT mulƟplier x Ie).

Their are 11 Long Time Pickup seƫngs ranging from are 0.50 to

1.00 Ɵmes x CT in steps of 0.05. The pickup value is set at a value

of approximately 1.12 x the seƫng with a tolerance of -10% to

+10%. An addiƟonal accuracy degradaƟon of ±5% occurs when

waveforms with signiĮcant harmonic distorƟon are present.

(For an overview of all available seƫngs see table 2.4 on page

2-12)

2.2.3.1 ้๔ۯۉୁDŽࡗሜԍࢺยዃDžIr

2.2.3.1 Long Time Pickup (Overload ProtecƟon seƫng) Ir

2.2.3.1.1 Long Time Delay (On overload ProtecƟon) LTD

2.2.3.2 Short Time Pickup (Delayed Short Circuit ProtecƟon) ST

2.2.3.1.1 ჽ้DŽࡗሜԍࢺDžLTD

2.2.3.2 ܌้๔ۯۉୁDŽჽ้܌ୟԍࢺDžST

!2.3ǖ߲߳ۨڦ!LTD!ݔྷዐኸۨࡗሜڪူࡗሜཌቄ้DŽڇ࿋ྺ௱Dž

Ҿጎሞᆶૌ႙ڦۉጱྃഗዐLjڼᅃ߲!TFUVQDŽยዃDž

ఇ๕၂๖๔ዕ!Mpoh!Ujnf!QjdlvqDŽ้๔ۯۉୁDž

ยዃۅăᅜሞยዃۅยۨୟഗܮۨۉୁ!Jsă

ᆩࢽᅜሞڼᅃ߲၂๖ೡฉፌܠยۨ! 7! ߲փ! ཞڦᆩࢽۉ

ୁ! JfLjยዃྺݴ๕! 2Ă1/:9Ă! 1/:8Ă1/:7Ă1/56! !

1/5!y!ୟഗۉୁܮۨኵ!JoLjኄၵݴ๕ሞ၂๖ೡฉ၂๖ྺ

ۉୁኵă

ඓۨڦۉୁยዃ! Js! ሞڼܾ߲!MU! ยዃ၂๖ೡฉยዃLjย

ዃྺᆩࢽۉୁኵ!Jf!ڦݴ๕ăDŽyMU!>!MU!ဣຕ!y!JfDžă

ᆶ!22!้߲๔ۯۉୁยዃLjݔྷྺ!1/61ڟ!2/11!y!DU

DŽօྺ!1/16Džă

๔ۯۉୁኵยዃྺሀڪᇀ!2/23!y!ยዃኵLjࠅֶྺ!.21&!

ڟ! ,21&ăհႚ٪ሞჹዘڦၿհ฿ኈ้Ljඓ܈ᅜምই

گ! Ġ6&DŽᆶ࠲ᆶᆩยዃڦ߁ຎLj൩֖ڼ! 3.23! ᄻ

ฉڦ3/5Džă

Nqsp!T-O႙ۉጱྃഗᆶ!33!߲ჽ้ݔྷLjྔႚᇑඤ

ىୟഗڦඤᇮૌຼă

!3/4!ଚକፌ܌ࢅፌڦჽ้ഄ!JFD!:58ݴૌăԨᆌ

ᆩ֩!7/2!ዐݔྷࣼྺ้ۉୁă

Ҿጎሞᆶૌ႙ڦۉጱྃഗዐLjڼܾ߲!SETUPDŽยዃDž

ఇ๕၂๖๔ዕ! Tipsu! Ujnf! QjdlvqDŽ܌้๔ۯۉୁDž

ยዃۅă܌้๔ۯࠀీยۨۉୁኵLjٳڟۉୁኵ้Ljۨ

้܌้ཌቄഐۯ! )Jtu*Ljยዃኵߵ้๔ۯۉୁยዃ!

Js! ႜۙবă๔ۯۉୁยዃኵڦስݔྷྺ! 2/6!ڟ!23/1!

)2*! ױᅜ้ยዃኵLjyMU! )Js*Ljօྺ! 1/6! y! MU!

)Js*ă֖!3/6ă

TU! ๔ۯۉୁኵ! )Jtu*! ࠅֶݔྷྺยዃۅڦ! .21&! ڟ!

,21&ăհႚ٪ሞჹዘڦၿհ฿ኈ้Ljඓ܈ᅜምইگ!

Ġ6&ă

2.2-02

NF1:ဣଚگუഘୟഗ

ຫׂ֡ፕ၂๖ೡఇ๕൸၍٪ഗҾጎথ၍

ୟഗ

֪

BREAKER LOCKS ACCESSORIES TESTS APPENDIX

ᆅჾ

ۉጱྃഗ

INTRO

TRIP UNIT

Table 2.3 : Overload Tripping Ɵmes at indicated overload levels per selected LTD band , in Seconds.

Ir C-2 C-3 C-4 C-5 C-6 C-7 C-8 C-9 C-10 C-11 C-12 C-13 C-14 C-15 C-16 C-17 C-18 C-19 C-20 C-21 Cmax

ፌ 7.8 23.4 46.7 62.3 93.4 125 156 187 218 249 280 311 374 436 498 560 623 685 747 810 872 934

ፌ܌ 4.0 12.0 24.0 32.0 48.0 64.1 80.1 96.1 112 128 144 160 192 224 256 288 320 352 384 416 448 480

ፌ 1.3 3.86 7.73 10.3 15.5 20.6 25.8 30.9 36.1 41.2 46.4 51.5 61.8 72.1 82.4 92.7 103 113 124 134 144 155

ፌ܌ 0.80 2.41 4.82 6.43 9.64 12.9 16.1 19.3 22.5 25.7 28.9 32.1 38.6 45.0 51.4 57.8 64.3 70.7 77.1 83.

6 90.0 96.4

x

1.5

3

7.2

ፌ 0.21 0.62 1.24 1.66 2.49 3.32 4.15 4.98 5.81 6.64 7.47 8.30 9.96 11.6 13.3 14.9 16.6 18.3 19.9 21.6 23.2 24.9

ፌ܌ 0.13 0.40 0.81 1.07 1.61 2.15 2.69 3.22 3.76 4.30 4.83 5.37 6.45 7.52 8.60 9.67 10.7 11.8 12.9 14.0 15.0 16.1

ۉݞࢺڪޙࢇ!

!

10b 10 20 30 40

Cmin

Motor ProtecƟon Class to IEC 947-4

Loading...

Loading...