MAINTENANCE

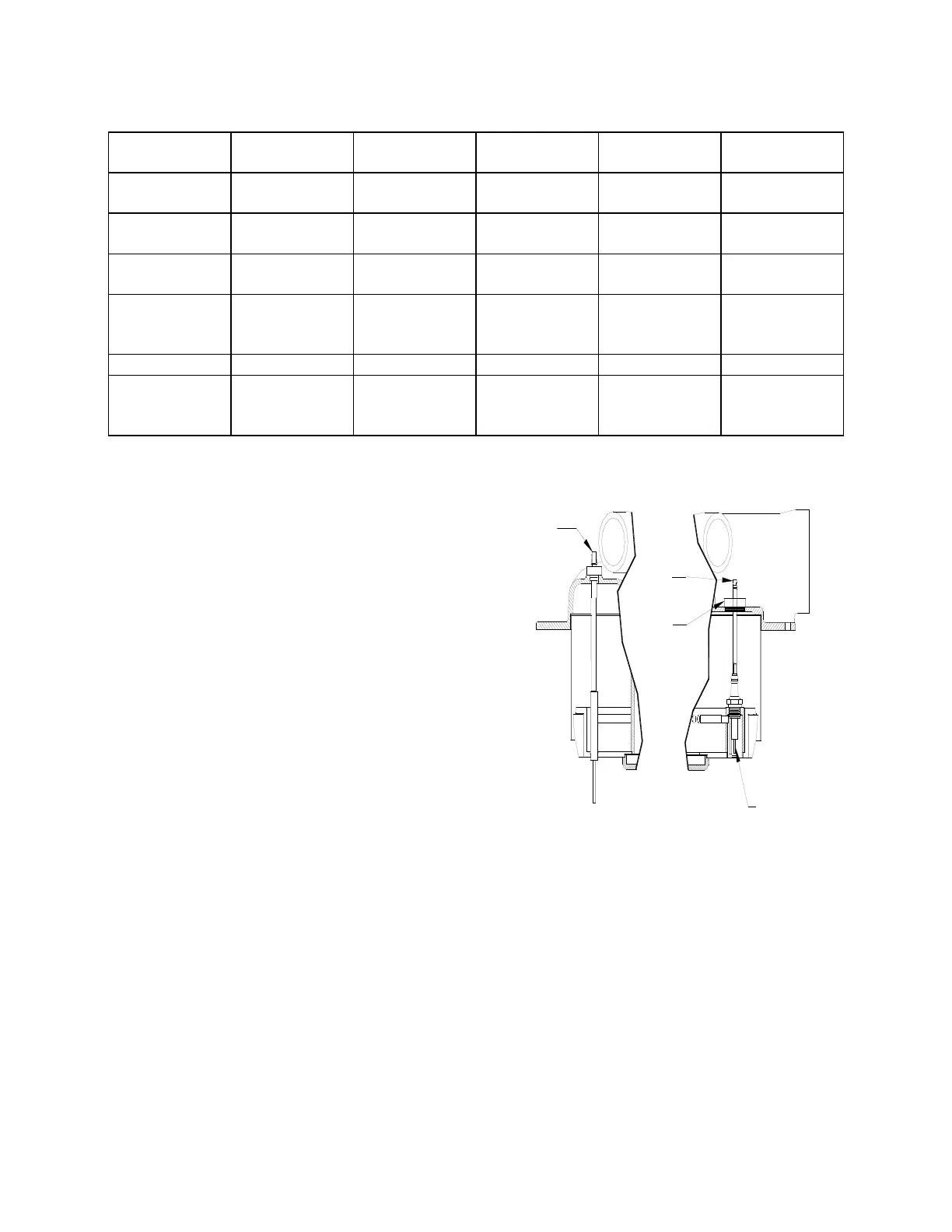

Table1 - Maintenance Schedule

SECTION ITEM 6 Mos. 12 Mos. 24 Mos.

7.2

Inspect Replace 15 mins.

7.3

Inspect Replace 15 mins.

7.4

Check Check 1 hr.

7.5

Safety

Chart in

20 mins.

7.7

*Manifold &

Tubes

clean if

4 hrs.

* Recommended only when unit will be run in an extreme condensing mode for prolonged periods of time.

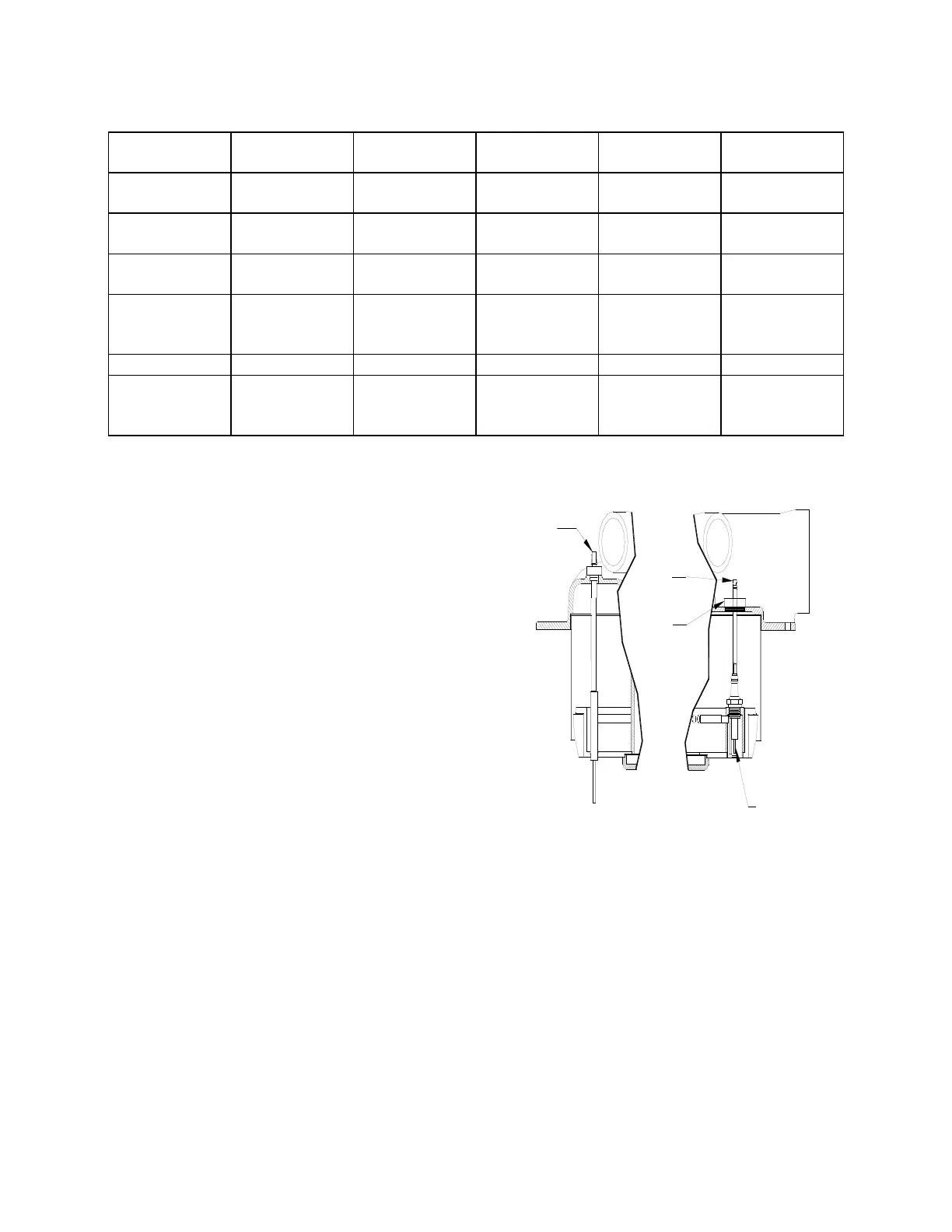

7.3 FLAME DETECTOR

The flame detector assembly is located in the

body of the burner (see Fig. 7.1A). The flame

detector may be HOT. Allow the unit to cool

sufficiently before removing the flame detector.

To inspect or replace the flame detector:

1. Put the green ON/OFF button on the control

panel, to the OFF position and disconnect

AC power to the unit.

2. Remove the side and top panels from the

unit.

3. Disconnect the flame detector lead wire.

Unscrew the flame detector and remove it.

(See Fig 7.1B)

4. Inspect the detector thoroughly. If eroded,

the detector should be replaced. Otherwise

clean the detector with a fine emery cloth.

5. Reinstall the flame detector hand tight only.

6. Reconnect the flame detector lead wire.

7. Reinstall the rear, side and top panels on

the unit.

7.4 COMBUSTION CALIBRATION

Combustion settings must be checked at the

intervals shown in Table 1 as part of the

maintenance requirements. Refer to Sections

4.2 and 4.3 for combustion calibration

instructions.

Figure 7.1B

Spark Ignitor and Flame Detector Location Cut-

Away View

7.5 SAFETY DEVICE TESTING

Systematic and thorough tests of the operating

and safety devices should be performed to

ensure that they are operating as designed.

Certain code requirements, such as ASME

CSD-1, require that these tests be performed on

a scheduled basis. Test schedules must

conform to local jurisdictions. The results of the

tests should be recorded in a logbook. See

Section 6-Safety Device Testing Procedures.

7.6 BURNER

SPARK PLUG

IGNITOR

CONTACTOR

FLAME

DETECTOR

IGNITOR

BUSHING

Loading...

Loading...