10

It may happen that, after receipt, the units are not to be immediately installed and

are kept in storage. In case of medium-long term storage, we recommend applying

the following procedures:

• Make sure there is no water inside the hydraulic systems.

• Do not remove the protections from the heat exchanger.

• Do not remove the plastic protective lms.

• Make sure that the electrical panels are closed.

• Before using the equipment, store all items provided in a dry and clean place so

that they can be used in the future. We recommend storing the unit in a dry and

sheltered place (especially for units intended for indoors).

NOTE The maximum storage temperature of the units depends on the type of

refrigerant contained, see table. Beyond this limit, there is a risk of refrigerant

leaking through the safety valves.

For unit installation it is important to perform the following preliminary preparation

tasks:

• When installing, make sure that the atmospheric or environmental agents do not

aect and corrode the cooling circuit components, causing the refrigerant to leak

in the environment and, if so, make the appropriate adjustments.

• The air-cooled units with fans are designed for outdoor installation. Contact Aer-

mec before making any type of installation.

• The water-cooled units are designed for indoor installation. Contact Aermec befo-

re making any type of installation.

• For the positioning of the air-cooled units for outdoor use, choose a place that is

not exposed to excessive wind (install windbreaks if the wind speed exceeds 2.2

m/s).

• The soil under the unit must be at, smooth and suciently strong to withstand

the weight of the unit with a full refrigerant load, as well as the occasional presence

of the normal maintenance equipment.

• In locations exposed to frost, if the unit is installed on soil, the support base must

rest on concrete columns with a depth greater than the normal depth of frost of

the soil. It is always advisable to build a support base separate from the main buil-

ding to avoid the transmission of vibrations.

• For normal applications, the rigidity of the unit and the positioning of point loads

allow for an installation that minimises vibrations. In the case of installations re-

quiring particularly low vibration levels, you can use the anti-vibration supports.

ATTENTION: The use of anti-vibration supports MUST be combined with the installa-

tion in the unit water piping of exible couplings. The anti-vibration supports must

be xed to the unit BEFORE it is earthed. AERMEC is not responsible for the choice of

capacity of the anti-vibration supports.

• The unit must be xed to the anti-vibration supports and these rmly xed to the

concrete base, see chapter weight distribution and minimum technical spaces

• Check that the contact surfaces of the anti-vibration supports are levelled to the

base. If necessary, use spacers or level the base but, in any case, make sure that the

anti-vibration supports rest at on the base surface.

• It is essential that the units are installed leaving sucient space around them to

allow easy access to the components for maintenance and repair purposes.

ATTENTION: It is important that the units are installed at. The improper installa-

tion of the unit invalidates the warranty.

Maximum storage temperature

Refrigerant Type Class Max. Temp. (°C)

R134a HFC A1 <50°C

R410A HFC A1 <50°C

R1234ze HFO A2L <50°C

R513A <50°C

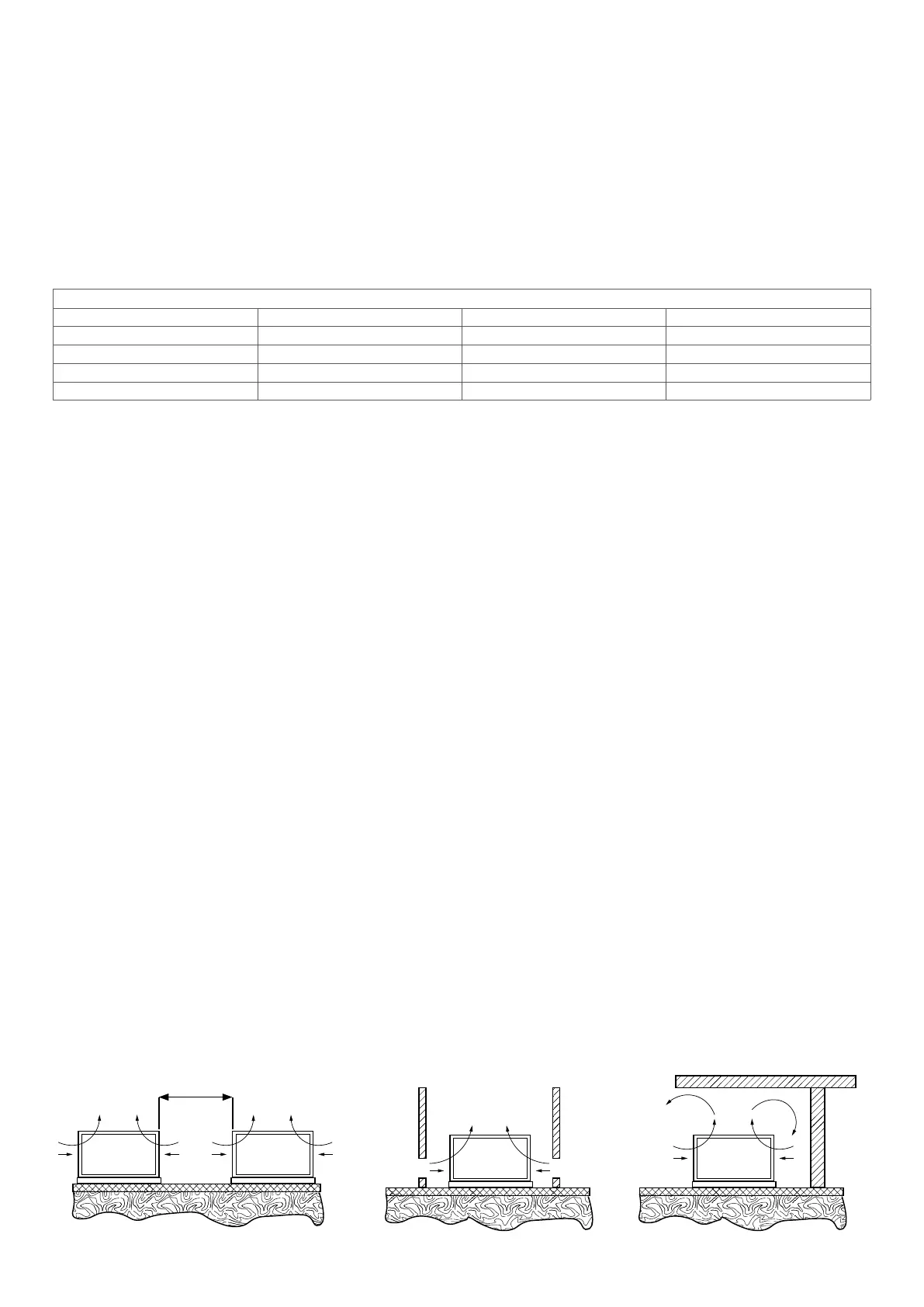

PLACEMENT AND INSTALLATION REQUIREMENTS

Recommended Installation

Windbreak

recommended with wind above 2,2 m/s

Installation not allowed

Recommended 2300mm

STORAGE

Loading...

Loading...