40

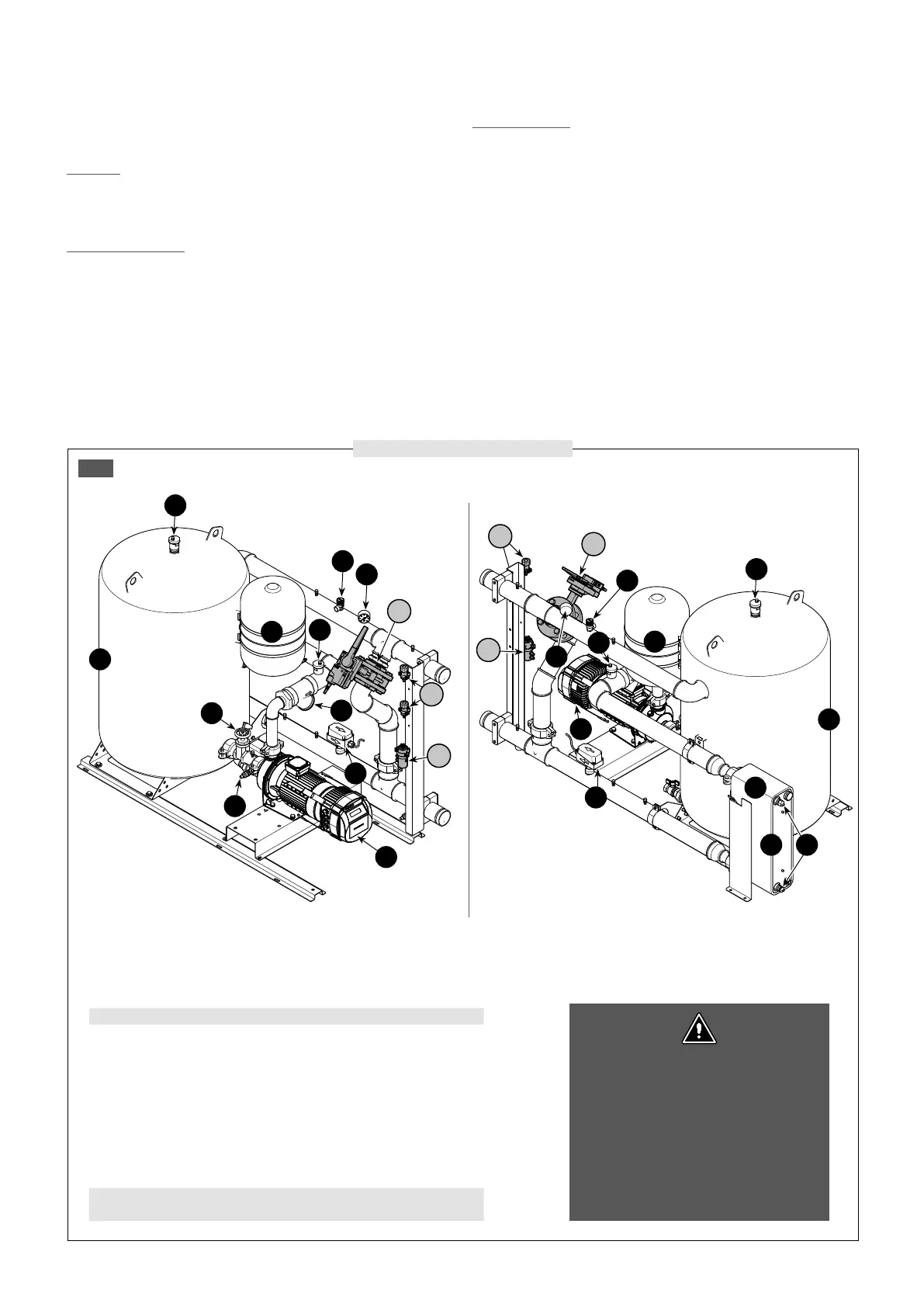

g . 1

1

3

2

4

6

5

5

5

7

7

8

9

10

10

11

11

12

13

15

15

16

12

13

14

14

16

5

4

VARIABLE FLOW RATE SYSTEMS ON THE PRIMARY CIRCUIT WITH HYDRONIC KITS W1W2W3W4

Congurations W1-W2-W3-W4 are designed for single-ring systems with a

variable ow rate.

BENEFITS

This type of system produces:

• a simplied hydraulic circuit

• lower electricity consumption for pumping

WHAT THEY INVOLVE

These options include as standard: (g.1)

• Pumping units with high or low head, with the pumps driven by an

inverter

• Dierential pressure transducer and absolute pressure transducers:

pressure sensors for ensure ow rate modulation based on the

pressure dierence measured between two precise points indicated

on the hydraulic diagram

• Bypass branch with a motorised valve to ensure the minimum ow

rate required by the heat exchanger in all operating conditions

HOW THEY WORK

The system that this solution is applied to must have a certain number of

terminals with 2-way valves (On-O or Modulating) that vary the ow rate

during adjusted operation.

During the system design phase, make sure there are an adequate number

of terminals with 3-way valves (not subject to ow rate variation on the

supply), to guarantee the minimum ow rate on the circuit compatible

with the machine limits.

The system automatically modulates the number of pump rotations - and

therefore the water ow rate - on the basis of the pressure dierence

measured on the unit (and resulting from the opening or closure of the

2-way valves).

IT is essential to guarantee terminal regulation systems that, during

modulation, envisage an overall ow rate variation less than 10% per

minute of the current ow rate. (g.2)

Be sure to respect the minimum water content (refer to the “System water

content” chapter).

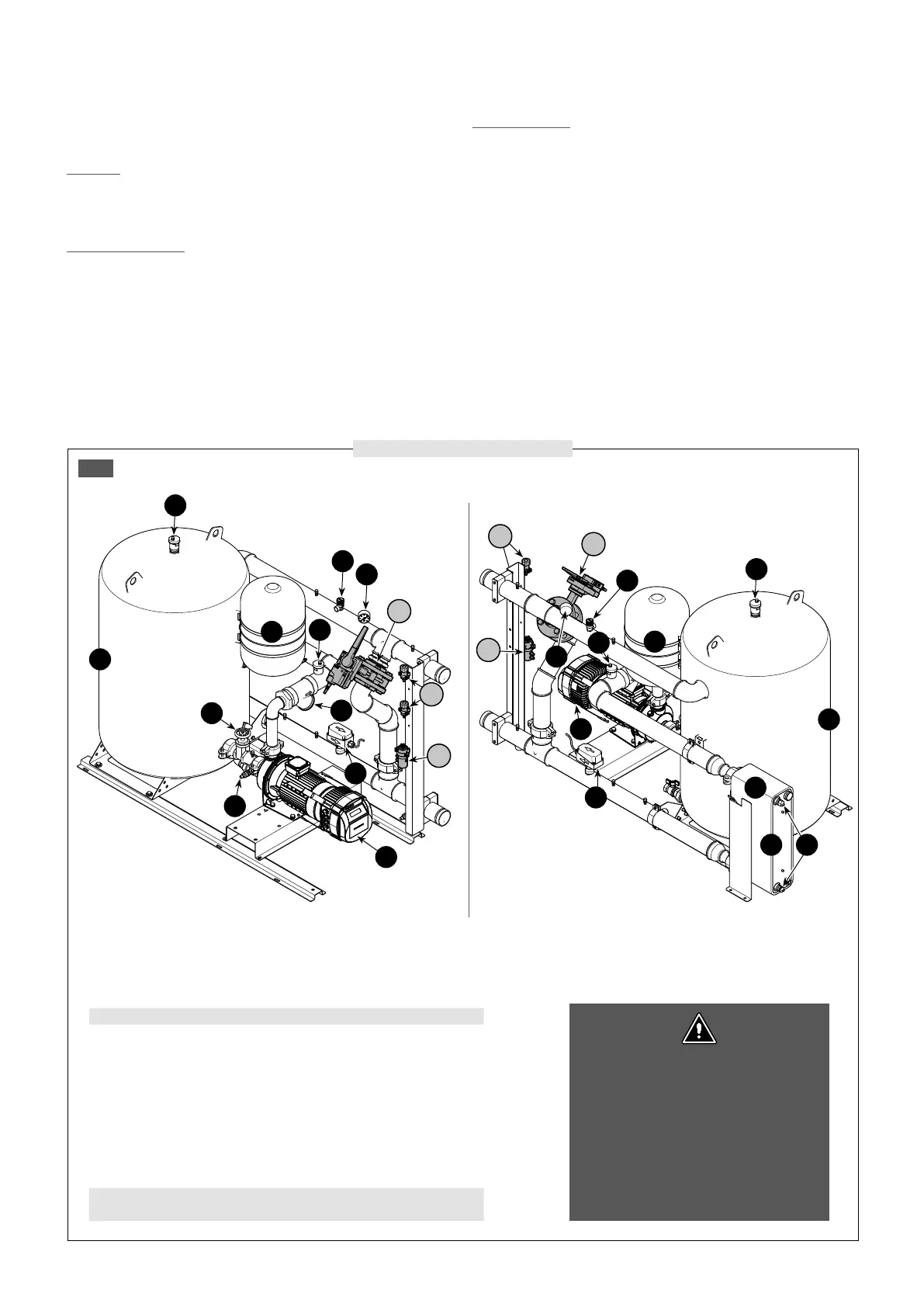

Hydraulic circuit con guration W3

The di erential pressure transducer (4) is

located on the rear of the unit, near the

two absolute pressure transducers (16), so

it can be accessed for maintenance. The

di erential pressure transducer (4) is the

starting point for the capillaries that are

then connected to the evaporator inlet

and outlet, as indicated in the hydraulic

diagrams on the following pages.

COMPONENTS PROVIDED AS STANDARD

1 Plate heat exchanger

2 Water temperature sensors

3 Antifreeze electric heater (standard in the heat exchanger and storage tank)

4 Di erential pressure transducer

5 Air vent valve

6 Water lter

7 Pump

8 Drain valve

9 Cut-o valve

10 System buer tank

11 Expansion Tank

12 Safety valve

13 Pressure gauges

14 Flow switch

15 Motorized by-pass valve

16 Pressure transducer

VARIABLE FLOW RATE SYSTEMS ON THE PRIMARY CIRCUIT WITH HYDRONIC KITS W1W2W3W4

Loading...

Loading...