is considerably easier to use than load resistors. It

eliminates the need for connecting resistors or rheostats in

parallel to handle power, it is much more stable than a

carbon-pile load, and it makes easy work of switching

between load conditions as is required for the load

regulation and load transient response tests. Substitution of

the electronic load requires minor changes to the test

procedures in this section.

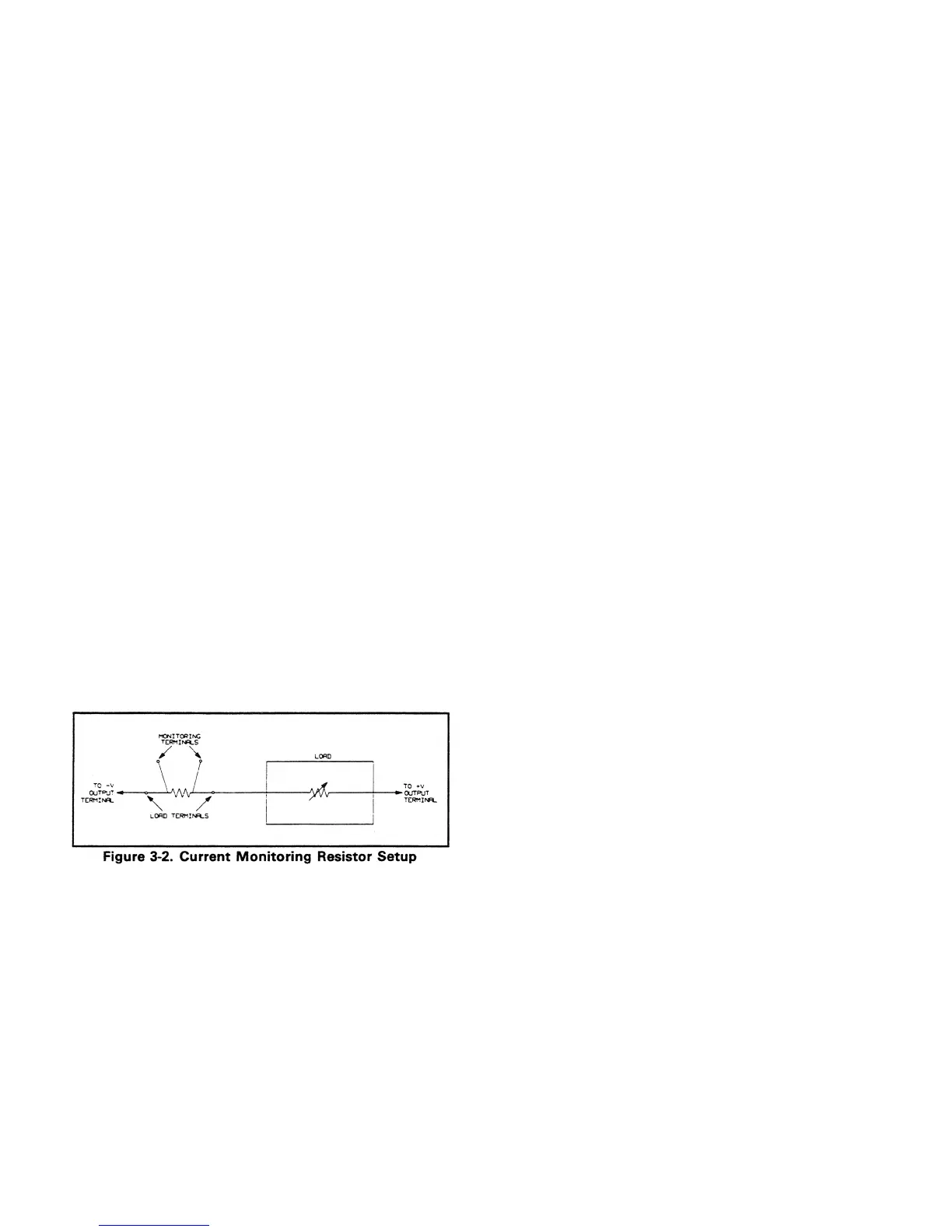

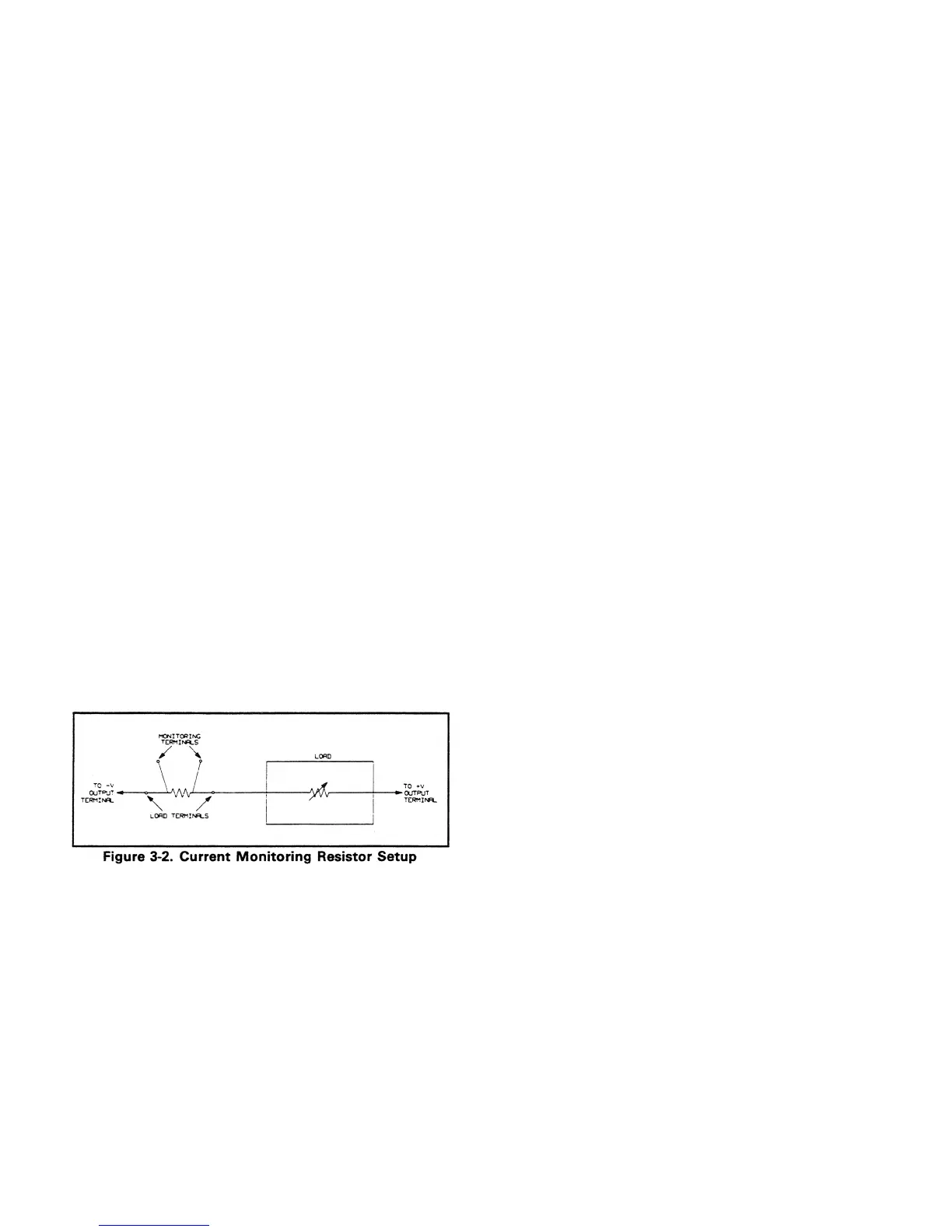

3-8 Current-Monitoring Resistor. To eliminate output

current measurement error caused by voltage drops in the

leads and connections, connect the current monitoring

resistor between the - V and the load as a four-terminal

device. Figure 3-2 shows the connections. Connect the

current-monitoring leads inside the load-lead connections

directly at the monitoring points on the resistor element.

performed using only the front panel keypad; however, an

current programming accuracy and readback accuracy tests.

The test procedures are written assuming that you know

controller or locally using the control keys and indicators on

the supply's front panel. Complete instructions on remote

and local programming are given in the Operating Manual.

NOTE

In the test programs that follow, the brackets < >

indicate a number to be sent. The < ch > specifies

the output channel number from 1 through 4. The

voltage and current values which are sent to the

specified output channel are given in Tables 3-2 and

3-3.

3-10 Constant Voltage (CV) Tests

3-11 CV Setup. If more than one meter or a meter and an

oscilloscope are used, connect each to the + S and - S

terminals by a separate pair of leads to avoid mutual

coupling effects. Connect only to + S and - S because the

unit regulates the output voltage that appears between + S

and - S, not between + V and - V. Use coaxial cable or

shielded 2-wire cable to avoid noise pickup on the test leads.

3-12 Voltage Programming and Readback Accuracy. This

and front panel display functions are within specifications.

a. Turn off the supply and connect a digital voltmeter

between the + S and - S terminals of the output to be

tested.

b. Turn on the supply and select the desired output

(OUTPUT SELECT key on the front panel).

c. Program the selected output channel to zero volts by

sending the string:

VSET < ch >, 0

d. Record the output voltage readings on the digital

voltmeter (DVM) and the front panel display. The

readings should be within the limits specified below for

the particular output type tested. Also, note that the

display indicates the output current and the CV, RMT,

and ADDR annunciators are on. Note that the output

current reading is approximately zero because there is no

load connected.

Prog. Accuracy Display Accuracy

Output (DVM Reading) (Front Panel LCD)

40WLV/80WLV 0 V ± 19mV DVM ± 25 mV

40WHV/80WHV 0 V ± 50mV DVM ± 55 mV

e. Read back the output voltage from the selected channel

10 OUTPUT 705; “VOUT? < ch > “

20 ENTER 705;A

30 DISP A

40 END

f. Record the value displayed on the controller. This value

should be within the DVM reading noted in step d and

the limits specified below.

Readback Accuracy

Output (Controller Display)

40WLV/80WLV DVM ± 20 mV

40WHV/80WHV DVM ± 50 mV

g. Program the selected output's voltage to the High Range

Full Scale value (20 V for 40WLV/80WLV or 50 V for

40WHV/80W'HV outputs) by sending the following

string:

VSET < ch >, < 20 or 50 >

h. Record the output voltage readings on the DVM and the

front panel display. The readings should be within the

limits specified below for the particular output type

tested.

Prog. Accuracy Display Accuracy

Output (DVM Reading) (Front Panel LCD)

40WLV/80WLV 20 V ± 31 mV DVM ± 35 mV

40WHV/80WHV 50 V ± 80 mV DVM ± 80 mV

i. Run the program listed in step e - Record the value

displayed by the controller. This value should be within

the limits specified below.

Readback Accuracy

Output (Controller Display)

4OWLV/80WLV DVM 30 mV

40WHV/80WHV DVM 75 mV

j. Repeat steps a through i for each output present in your

supply.

3-4

±

±

3-9 GPIB Controller. Most performance tests can be

GPIB controller is required to perform the voltage and

how to program the supply remotely from an GPIB

the GPIB by entering and running the following program:

test verifies that the voltage programming, GPIB readback,

An GPIB controller must be used for this test.

Loading...

Loading...