Chapter 3 Calibration Procedures

Recommended Test Equipment

47

3

Recommended Test Equipment

The test equipment recommended for the performance verification and

adjustment procedures is listed below. If the exact instrument is not available,

use the accuracy requirements shown to select substitute calibration

standards. If you use equipment other than that recommended in Table 3-1, you

must recalculate the measurement uncertainties for the actual equipment

used.

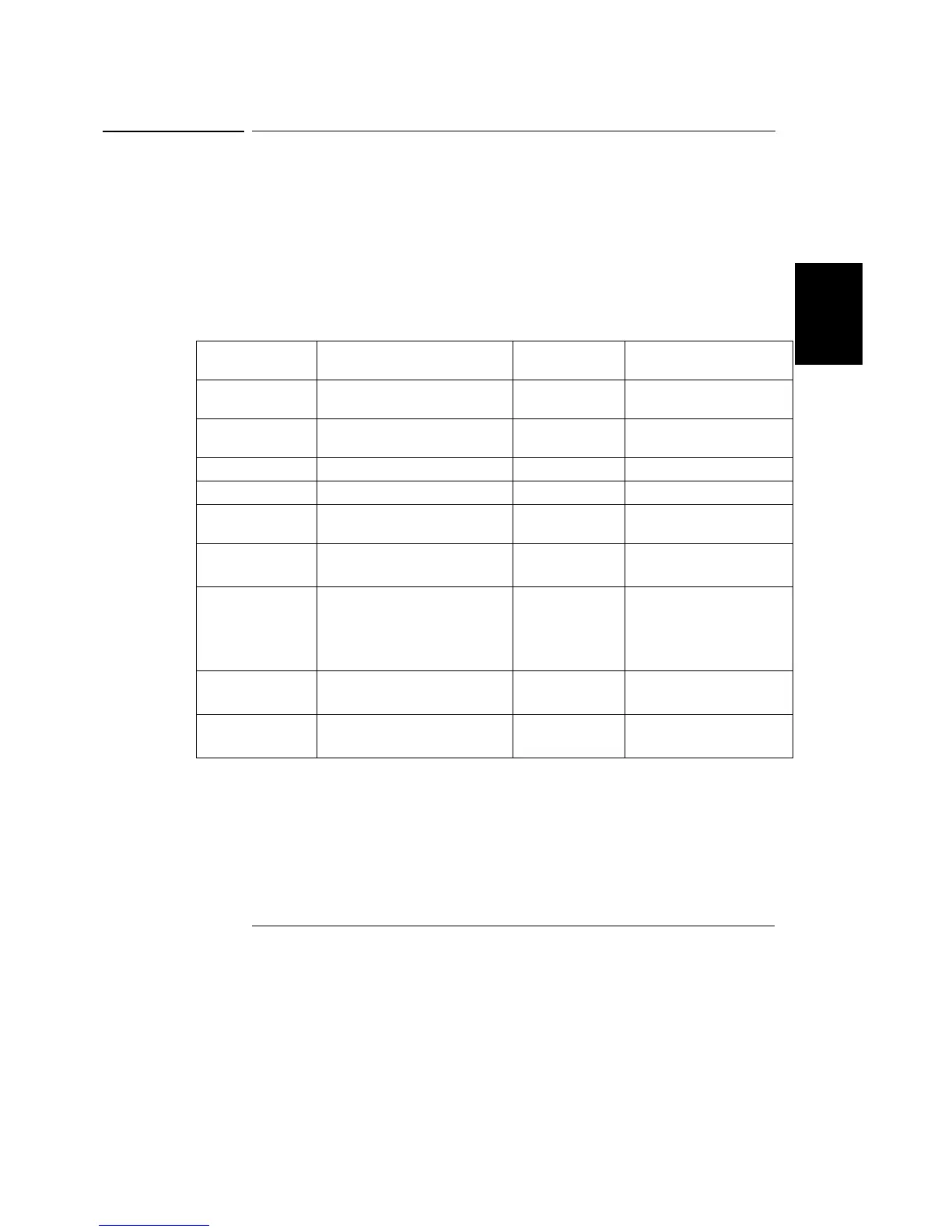

Table 3-1. Recommended Test Equipment

[1]

It is recommended to use a current monitoring resistor after calibration to

find the accurate resistance.

Instrument Requirements Recommended

Model

Use

GPIB controller Full GPIB or RS-232 capabilities Agilent 82341C

interface card

Programming and readback

accuracy

Oscilloscope 100 MHz with 20 MHz bandwidth Agilent 54602B Display transient response

and ripple & noise waveform

RMS Voltmeter 20 Hz to 20 MHz Measure rms ripple & noise

Coaxial cable Agilent 10502A Measure rms ripple & noise

BNC female to

banana plug adapter

Agilent 1251-2277 Measure rms ripple & noise

Digital Voltmeter Resolution: 0.1 mV

Accuracy: 0.01%

Agilent 34401A Measure dc voltages

Electronic Load Voltage Range: 60 Vdc

Current Range: 60 Adc

Open and Short Switches

Transient On/Off

Agilent 60502B Measure load and line

regulations and transient

response time.

Resistive Loads

(R

L

)

(0.4

9, 300 W/2.0 9, 300 W)* Measure ripple and noise

Current monitoring

Resistor (Shunt)

[1]

Model: A-H

Constant current test setup

*For Agilent E3633A Model **For Agilent E3634A Model

(0.01

9, 0.01%)

(3.5 9, 300 W/12.5 9, 300 W)**

ISOTEK Co.

Loading...

Loading...