38mm (1-1/2")

slope

of hull

Installation

WARNING: Always wear safety goggles and a dust mask.

CAUTION: Install the bracket before attaching the sensor.

Hole Drilling

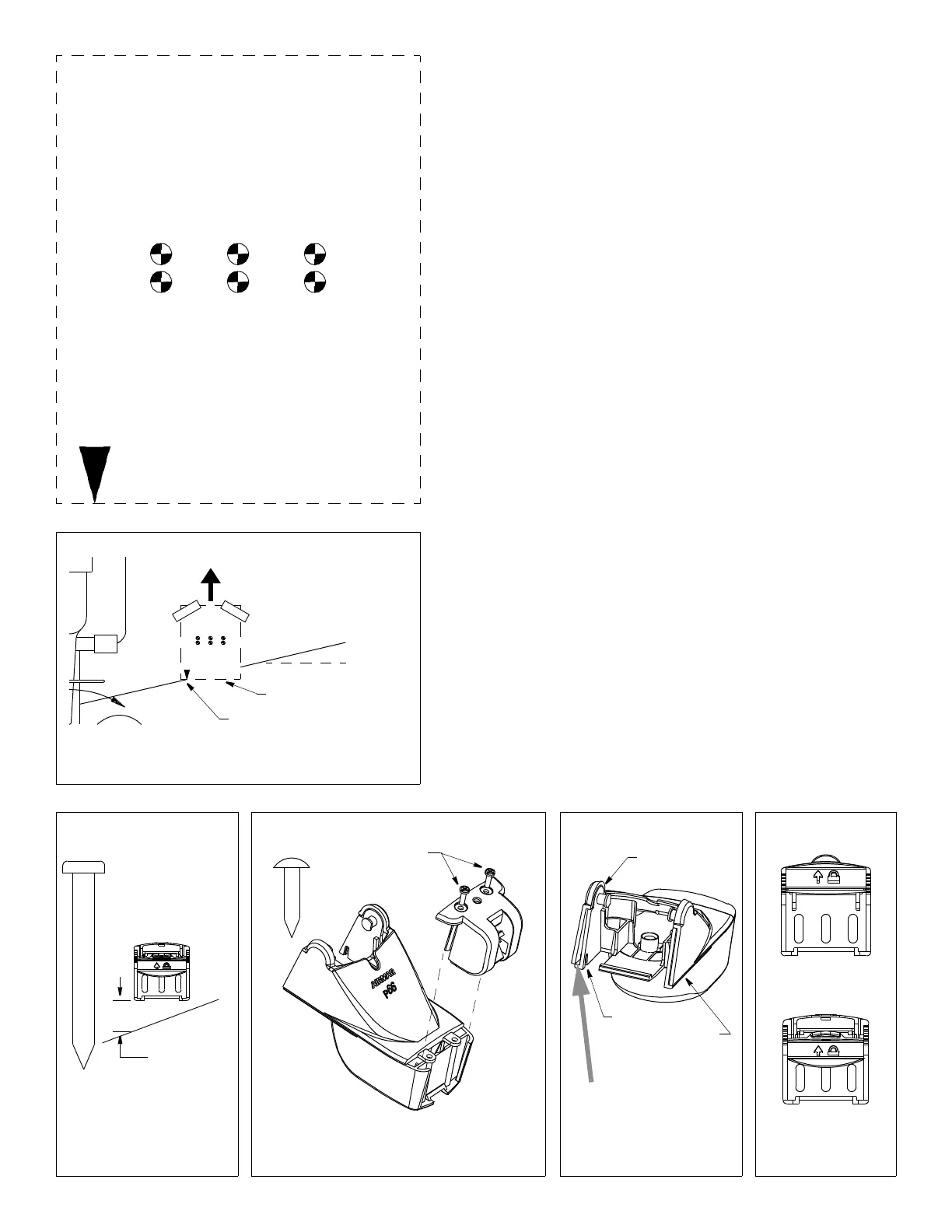

1. Cut out the template (see Figure 3).

2. At the selected location on the starboard side of the hull, position the

template, so the arrow at the bottom is aligned with the bottom edge of

the transom (see Figure 4). Being sure the template is parallel to the

waterline, tape it in place.

3. Using a 4mm, #23, or 9/64" bit, drill three holes 22mm (7/8") deep at

the locations indicated. To prevent drilling too deeply, wrap masking

tape around the bit 22mm (7/8") from the point.

Fiberglass hull—Minimize surface cracking by running the drill in

reverse until the gelcoat is penetrated.

Plastic Shim

• Standard transom (13° transom angle)—The bracket is designed for

a standard 13° transom angle. The shim is NOT needed for this

installation. Go to "Mounting the Bracket."

• Stepped transom and jet boats (3° transom angle) —Use the shim

with the taper down.

• Small aluminum and fiberglass boats (20° transom angle)—Use the

shim with the taper up.

• If you are unsure about using the shim, do one of the following:

• Measure the transom angle of your boat using an angle finder. Then

follow the instructions above for your transom angle.

• Experiment with the shim. Follow the instructions: “Mounting the

Bracket”, “Attaching the Senor to the Bracket”, and “Checking the

Angle and Projection.”

Mounting the Bracket

1. Apply marine sealant to the threads of the three, #10 x 1-3/4", self-tapping

screws to prevent water seepage into the transom (see Figure 5). Screw

the bracket (and shim if needed) to the hull. Do not tighten the screws.

2. Using the vertical adjustment space on the bracket slots, slide the bracket

up or down until the distance between the bottom left corner and the bottom

of the transom equals 38mm (1-1/2"). Tighten the screws.

Figure 4. Template position

align template arrow with

bottom edge of transom

Align template vertically

slope of hull

waterline

Align arrow with bottom of transom

Figure 3. Template

for starboard side of boat

Drill at locations labeled “B”

for transom angles 16° through 22°

(most small aluminum boats)

Drill at locations labeled “A”

for transom angles 2° through 15°

(most boats)

A

B

A

B

A

B

A

B

Figure 5. Distance between

corner of bracket and

bottom of transom

2

Figure 8. Bracket

retaining cover

Figure 6. Speed sensor or blank

Figure 7. Cover

closed

opened

mounting ears

screws

cover

speed

sensor

transducer

housing

(some installations)

bracket

screw

actual size

actual size

(self-tapping

#6 x 5/8")

self-tapping

screw

(some installations)

insert screw-

driver here to

remove cover

cover

tab in slot

flush with

housing

c

o

v

e

r

h

o

u

s

i

n

g

Copyright © 2003 Airmar Technology Corp.

Copyright © 2003 Airmar Technology Corp.

Copyright © 2003 Airmar Technology Corp.

Copyright © 2003 Airmar Technology

Copyright © 2003 Airmar Technology Corp.

parallel to waterline

parallel to waterline

Loading...

Loading...