138 AS-D+—AS-P Series Instruction Manual

AirSep Corporation

6. Turn the stem (4) so that the valve is fully closed.

Remove body seals (6) and seats (5). Body seals may be

tightly compressed in their grooves. Use extreme care

when prying them out. Damage such as scratches to the

bottom of the groove will cause leaks. If the seats are not

easily removed, gently tap the ball (3) with a piece of

wood or other soft material.

7. Remove the ball (3).

8. Remove the lower stem nut (16) and the compression

ring (21).

9. Press the stem (4) from the top into the valve body (1)

and remove it through the end of the body.

10. Carefully pry out and discard the old stem seals (8), the

stem bearings (24), and the secondary stem seal (7),

being careful not to damage the bearing surfaces.

4.3 Assembly

The following instructions are for in-line assembly. For bench

assembly, which may be more convenient, follow a similar

sequence by holding the valve in a vise by one end cap. Use

care not to cut or scratch the seats, seals or sealing surface.

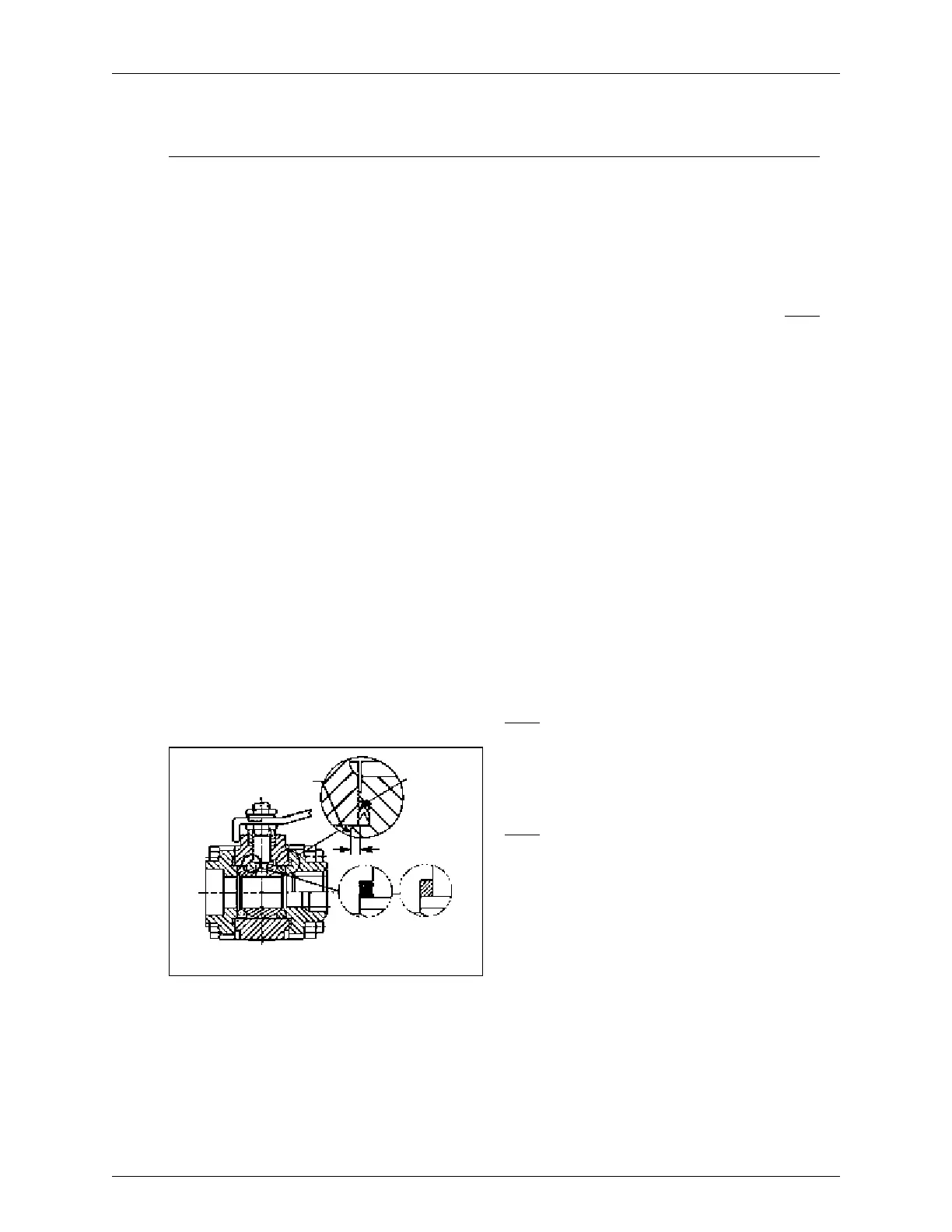

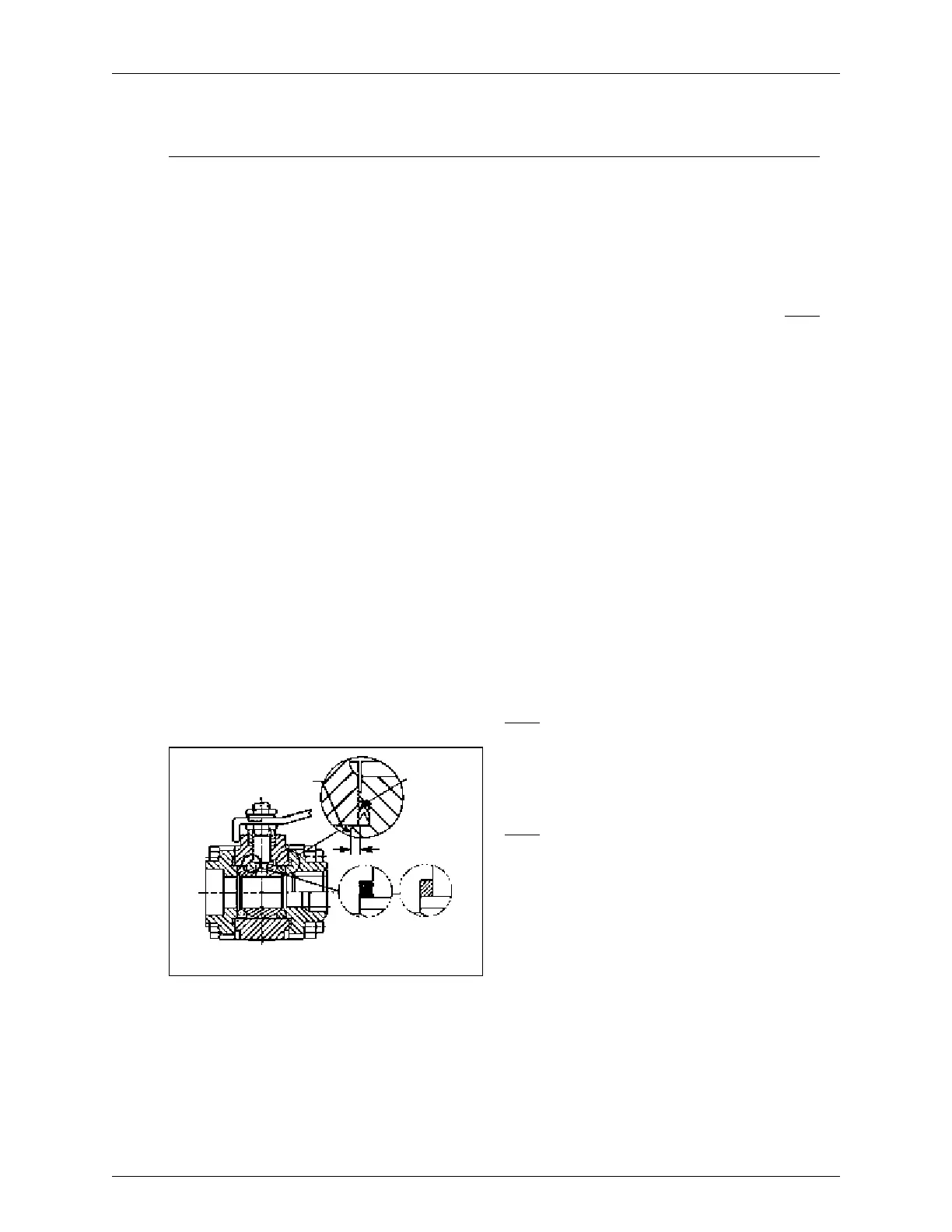

1. With the valve swung to the out-of-line position, insert

from the inside of the body a stem bearing (24), a sec-

ondary stem seal (7), then another stem bearing (24)

into the stem bore. For non-Fire-Tested valves use one

stem bearing (24). (See Figure 3 and parts list.)

2. Insert the stem (4) horizontally into the body bore (thread-

ed end rst). The blade at the ball end of the stem must

be vertical (see Figure 2A and 2B). Guide the stem into

the stem hole being careful not to scratch the bearings.

3. Holding the stem in place from the bottom, install two

stem seals (8), a compression ring (21) from the outside and

thread on one stem nut (16) until the stem starts to turn.

4. Place a wrench through the body on the bottom stem

blade to hold the stem stationary. Place another wrench

on the stem nut and turn the nut down until the seals

are bottomed and the stem comes snugly into place,

applying the torque shown in (Table 2).

5. Align the stem blade with the ball slot. Insert the ball (3),

and rotate the stem (4) to the ball closed position.

6. Working at either end of the body (1), place a seat (5)

into the body. Fit it snugly against the closed ball. NOTE:

The sealing surface of the seat is toward the ball (See

Figure 4).

7. Place a body seal (6) into the machined sealing groove

of the end caps (2) (see Figure 3). Be certain the groove

and seal are clean.

8. Repeat instructions 6 and 7 for assembly at the opposite

end.

9. Turn the stem to the full ball open position.

10. Swing the entire body assembly back into the properly

aligned and interlock position between the end caps,

being careful not to scratch the body seals. Caps may

have to be spread slightly to accept the body.

11. Close the valve.

12. Bolt the valve together with lubricated body bolts (52)

and nuts (53). Tighten these bolts evenly and alternate-

ly. (See Table 1 for the torques and lubricant.)

13. Attach the handle (17), the Shakeproof Washer (19) and

secure them with the stem nut (16) (See Table 2 for

torques).

5. REPAIR KITS

NOTE: FIRE-TESTED repair kits include two seats (5), two

stem seals (8), two stem bearings (24), a secondary seal

(7 and two 316 stainless steel/graphite body seals (6). The

body seals are suitable for valves with carbon steel or 316

stainless trim. Consult the factory for replacement parts of

valves with trim other than carbon or stainless steel, and for

seat material not listed or for special services.

NOTE: NON-FIRE-TESTED repair kits include two seats

(5), one stem bearing (24) and two body seals (6). The

body seals are suitable for valves with carbon steel or 316

stainless trim.

Figure 3

Surface A

Surface A

1/16” (1.6 mm)

Interlock

non fire-testedfire-tested

IMO 3/18

IMO-202 EN 5

Loading...

Loading...