r

U

ADJUSTMENT

OF TAPE

TRANSPORT

UNIT

1. ADJUSTMENT OF

PINCII

WIIEEL

It is imporlant that the piich

wheel shaft i5

kept nr

complcte alignmentwith

the capstan shaft.

A properpinch

wheel

pressur€

is bctween

1.000 and I,150 grahs

whcn the

unit is ope.ated

at the tapc spccd of7-t6

ips. Any devia'

tion

from this specificalion

will result in wow and

flutter.

Check

I'in.h

wheel pre"su,. bv r

.1-.ring

'cale

at.d.

if

r,ecesar

y.

ad

ju"r

rhe pin, h

whpFl

load 5t.inB.

2, ADJUSTMENT OF

TAKE.UP IDLER WHEEL

The

take-up ;dlm wheel

must

be

kcpt in complete align-

ment ltith thc takc-up reel shaft.

Whcn the unit

is set in

fast forward condition,

thc idler

whe€l will contact to the

upper knu.led

wheel

of

the takc-up reel shaft

assembly.

and it

will

contact

to thc lower kn urled

whccl du.ing record

or

play modc. Adjust idlerwhccl

load spr;ngsoihatlhc

idler

wheel pressurc is kept between 50

and 80 grams.

The

;dler

qh..l

rapidlv

wear.

:f Ihf pre*u,.

b

Px,.ssi\c.

The slippage occurs

if thc prcssu.e

is smallef thaD the

3. ADJUSTMENT

OF

REWIND IDLER

WSEEL

The .c\rind

idler

whccl

must be kcpt in complete

align-

mcnt with thc rewi.d

reel

shaft. The amount

of

pressurc

to the k,,urlcd

motor bushing should be maintained

about

50 gfams during rewidd ope.ation. Adjust both thc idler

load spriog aDd

rewind roller.

4. ADJUSTMENT

OF

INTERMEDIATE WHEDL

Thc

intcrnediatc

wheel

is located between the

rewind

idler

whccl

and thc rubbe. ring vhich is uscd on the uppe.

part

of

the supply

reel shaft assembly. When

the unit is

sct in rewind mode, it will

contact

to thcsc parts sihul-

taneously deliverins torque of

motor. An

adequate

pres-

su.cis50grams. Adjust thc load sp.;ngofthc inrermed;ate

wheel if the

pressure is not sufrc;ent.

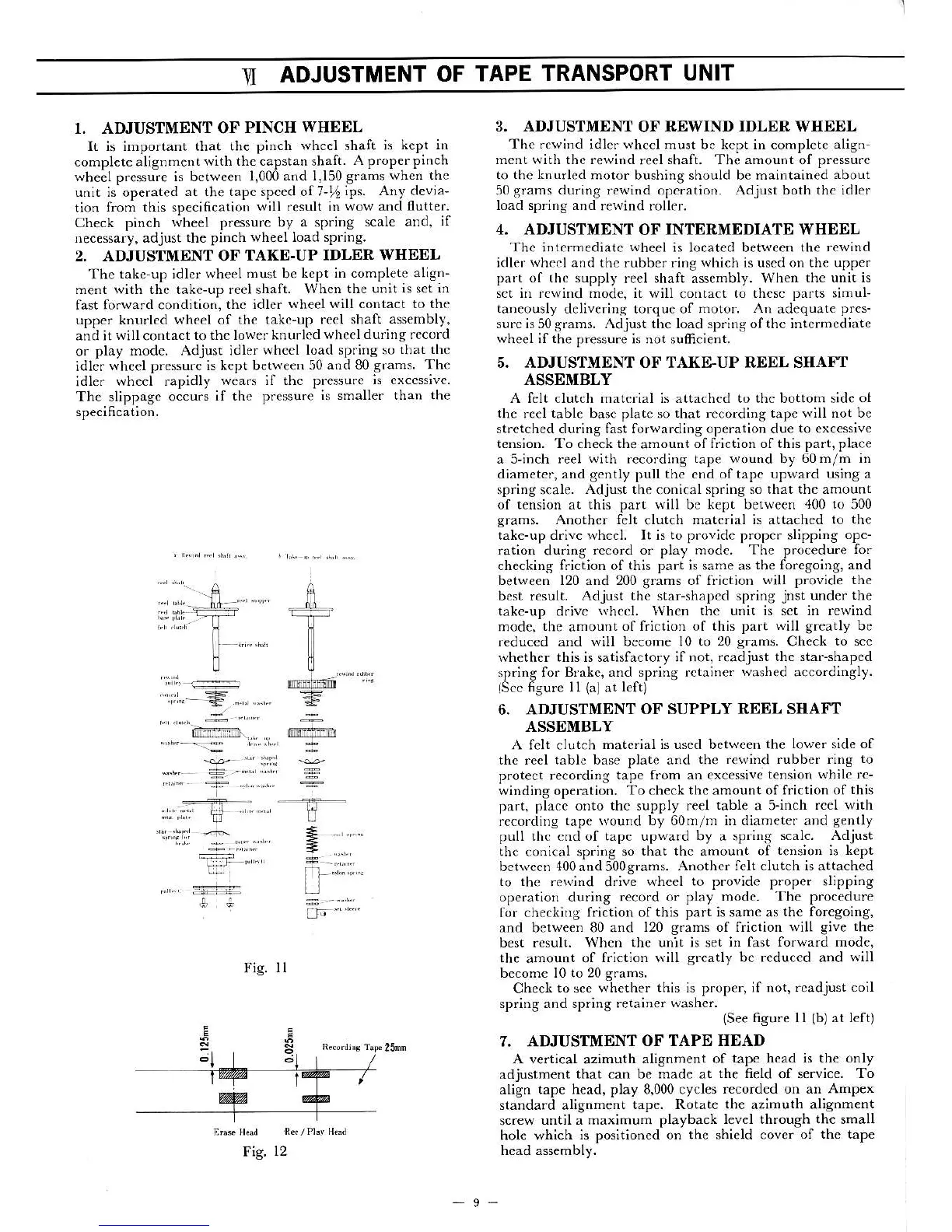

5. ADJUSTMENT OF TAKE-UP REEL SIIAI'T

ASSEMBLY

A felt clutch mat.rial is attachcd to the bottom sid€

ol

the

reel

table

basc plat€ so

that reco.ding tapc w;ll not bc

stretched during lhst forwafding operation due

to

excesivc

tension. To check the

amoudt

of friction of this part, plac€

a S'inch reel

with

fecordins

tape wound by 60m/m in

diameter, and gently pull the cnd of tapc upwarcl

using a

spring scale.

Adjust the

conical

sp.ing so that thc amount

of tension at this part will bc kept between

400 to

500

grams. Anoth€r felt

clutch

matoial ;s

attached

to

the

takc-up drive wheel. It is to pfovide proper slipping

opc-

ration

du.ing

record or play modc. The procedu.e

for

checkins friction of

this part

; same as

the foregoing, and

between 120 and 200 grams of frictioD

will provide the

best result.

Adjust the

star-shapcd

spring

jnst

under

the

takc-up dr;ve

whcel.

lvhen

the unit is

set

in rewind

mode,

the

amou.t

of f.iction of this part

will greatly

be

reduced and \viil become I0

to 20 grams.

Check

to scc

rvhether this is satisfactory ;f iot,

readjust the star-shaped

spring

fo. Bfakc, and spring rctainef

washed

accordingly.

lscc

fisure

ll

(al

at

lefo

6. ADJUSTMENT

OF SUPPLY REEL SIIAFT

ASSDMBLY

A felt clutch

matoial is uscd between

the love.

side

of

thc reel table base plate and

the .ewind rubbcr ring

to

protect reco.ding

tape from an excesive

tension \th;le re-

winding operation.

To

check

thc

amount

offriction of

this

pa.t, place onto thc supply reel

table

a 5-inch

rcel with

rcco.ding

tape wound by 60m/m in diameter and

gently

pulL thc cnd of tape upward by a spring

scale. Adjust

thc

conical sp.ing so

that thc amount of

tens;on ;s kept

bctwecn 400and500grams.

Anothc. fclt clutch is attached

to thc re\v;nd

drive

wheel to provide

proper

sl;pping

ope.atioD cluring

reco.d or play mod.. The procedure

for checkn)g

friction of this part is same as

the

foregoing,

and betwe€n 80 and

120

s.ams

of friction will give

the

best

result. Whcn

the

unit

js

set

;n fasi forward modc,

the

amount

of f.;ction will greatly be reduced and

will

become l0 to 20

grans.

Check

to

sce

whether this is proper, if not,

rcadjust coil

spring and spring r€tainer

washc..

{See

figure I I

(b)

at left)

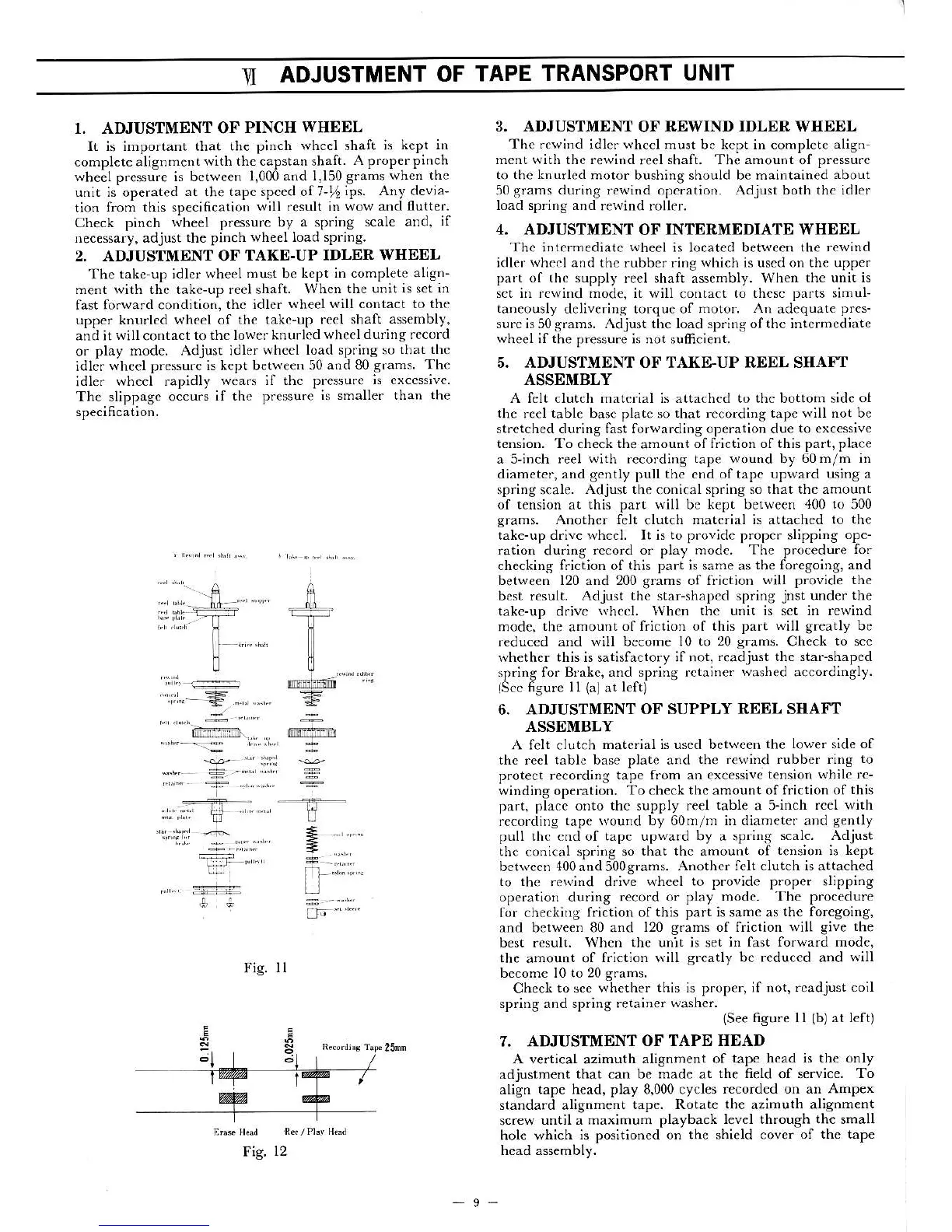

7. ADJUSTMENT

OF TAPE HEAD

A

vertical azimuth

alignment of

tape head is the only

adjustment

that

can

be made at

the field

of service.

To

align tape head, play 8,000 cycles

recordcd on an AmP€x

standard alignment

tape. Rotate

th€

azimuth al;gnment

sc.ew

until a maximum

playback level through the small

hole which

is positioned on the shield cover

of the tape

head assembly.

-9-

..t,

;

Fig.

ll

R(/.Ly Hli

Fig.

12

:ir".

=..".".,..

Loading...

Loading...