.UN

MAINTENANCE PROCEDURES

1. LUBRICATIONINSTRUCTION

For maximum senice life and optimum

performance, lubricate

the

parts

id€ntified

below after each 500

hours of

ope.ation. Use only

light machine oil of

good quality

Motor

3

drops

Drive Capstan

Shaft

2 drops

Rewind Idler Wheel

Bearing and wind take-up Idler Bearing. I drop

Intermediate Idler Bearing

I clrop

Pinch Wheel Bearing

2 drops

Take-up and Supply Reel Shaft Bearing &

2 drops

Also apply

a liberal frlm oflight machine

grease to

each roller surface of

all levers and cams.

CAUTION: DO

NOT

OVER-LUBRICATE.

WIPE OFF EXCESS OIL BY A COTTON SWAB

SOAKED IN ALCOHOL.

O'THERWISE, THE OVER.FLOWED LUBRICANT MAY

BE SCATTERI,D

DURING

OPERATION,

THE RUBBER COMPONENT PARTS

WILL BE DETERIORATED.

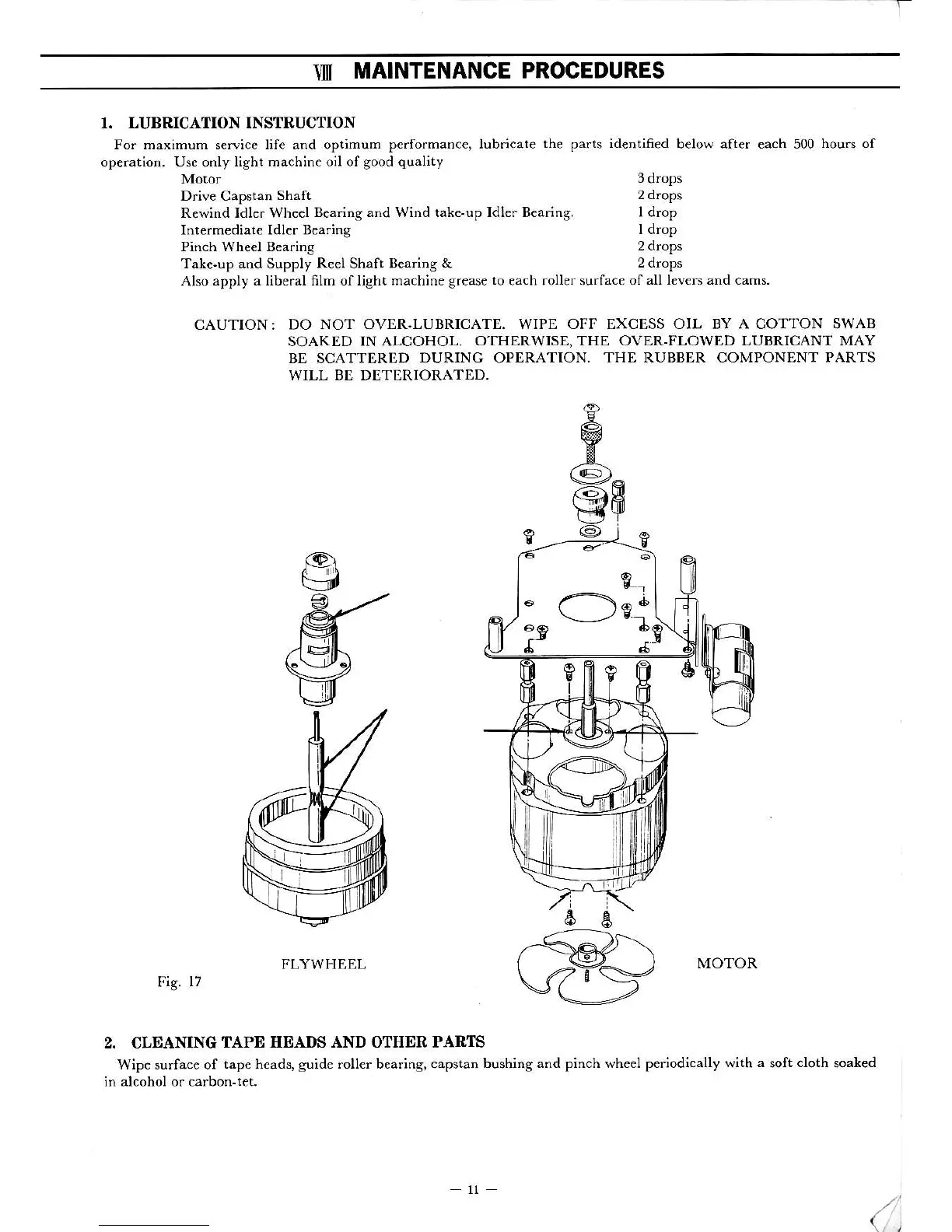

FLYWHEEL

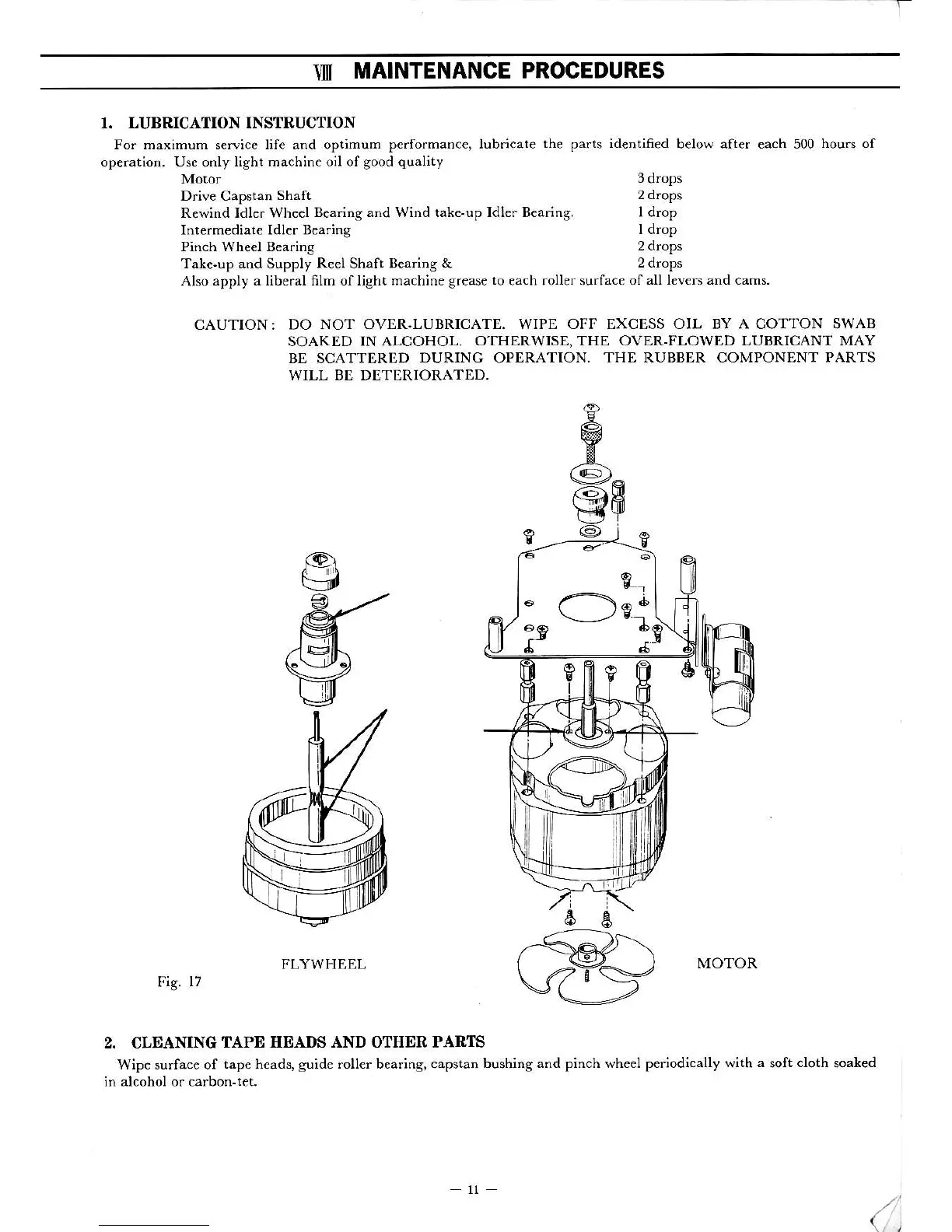

MOTOR

Fig.

17

2. CLEANING

TAPE HEADS AND OTHER PARTS

Wipe surface of

tap€

h€ads,

guide roller bearing, capstan

bushing and pinch wheel periodically with

a

soft

cloth

soaked

in alcohol or carbon-tet.

'

tt.6

r.-'-'''

r

It

Loading...

Loading...