Y

TRANSPORT MECHANISM

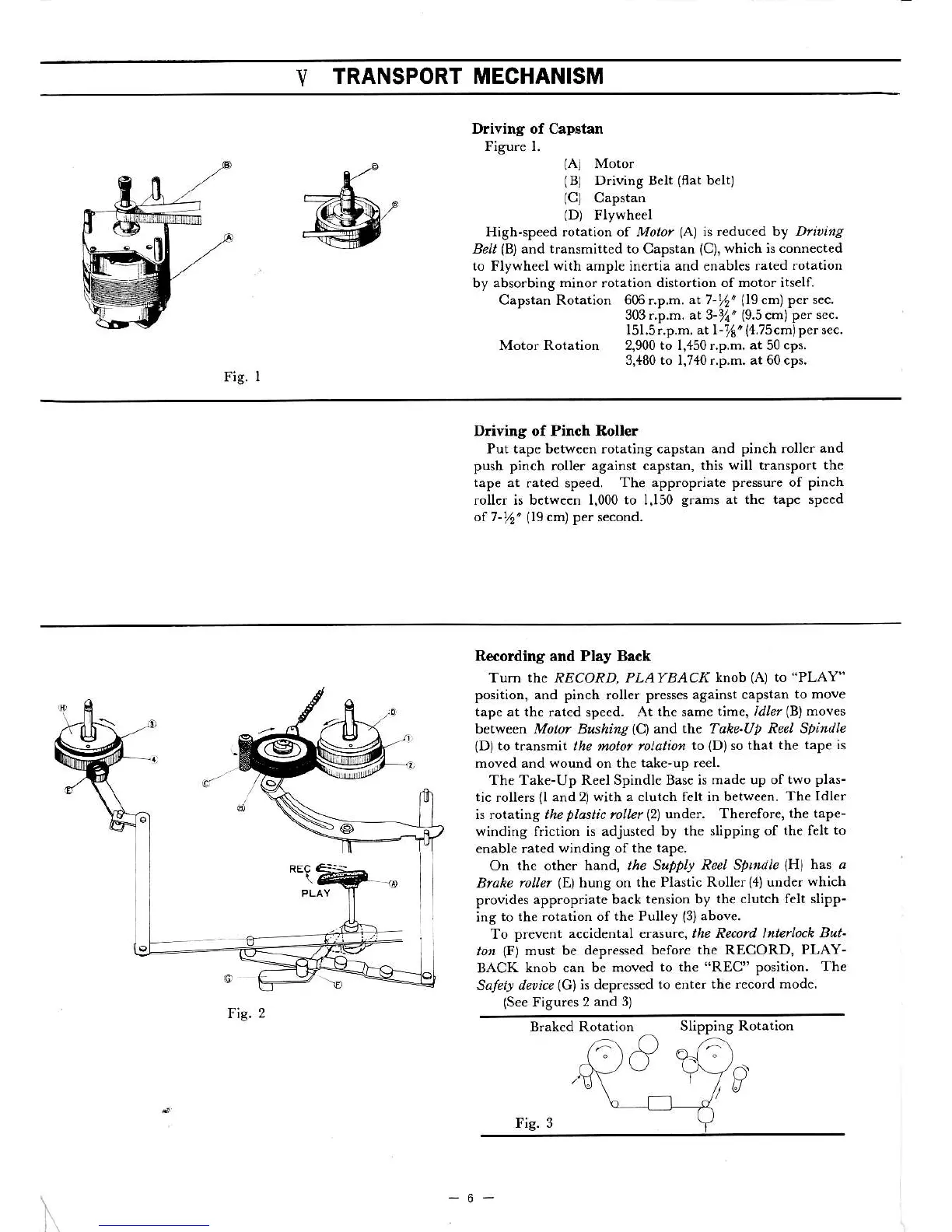

Driving of Capstan

Fjgure l.

{Aj

Motor

(B)

Driving Belt

(flat

belt)

(C)

Capstan

(D)

FlYwheel

High-speed rotation of Mot /

(A)

is reduced by D/trire'

Br,

(B)

and transmitted to Capstan

(C),

which is connected

to Flywheel with ample inertia and €nables rated

rotaiion

by absorbing

mino.

rotation

distortion ofDotor itself.

Capstan Rotation 606 r.p.m.

at 7-%'(l9cn)pe. sec.

303r.p.m. at 3-%'(9.5 cm)

per sec.

l5l.5r.p.m, at l

-16'

(4.7s

cmlper sec.

Motor Rotation 2,900 to 1,450 r.p.m. at 50 cps.

3,480 to 1,74{r.p.m. at 60cps.

Fig.

I

Driving of Pinch Roller

Put tape between rotating capstan and pinch roller

and

push pinch

rouer

against

capstan,

this will transport

thc

tape

at rat€d spe€d.

Th€ appropriate pressure of

pinch

roller is between I,000 to I,150

grams at the tape sp€ed

of 7-%'

(19cm)

per s€cond.

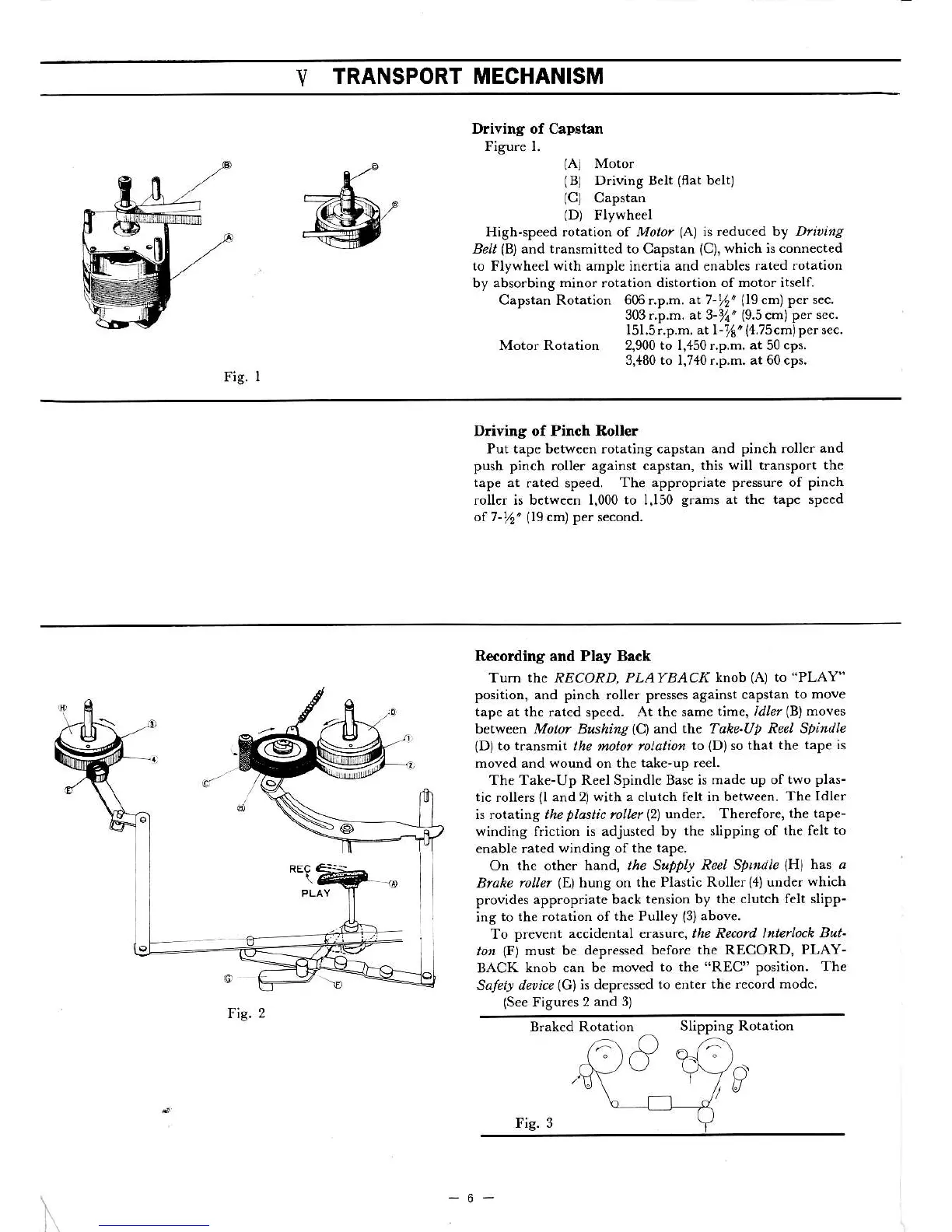

R€coding and Play Back

TuJ[ rhe RECORD, PLA rB,4Cf

knob

(A)

to

"PLAY"

position, and pinch roller presses against capstan

to move

tape at the rated

sp€ed.

At the same time,

Idlel

(B)

moves

between

Motor &tshitag

ICI

znd t}:'e Tahe-Ut Reel Spindle

lD)

b rr^ns'lr.it the motol /rldtro,

to

{D)

so that th€

tape is

moved and wound on the take-up re€I.

The Tak€-Up Reel Spindle Base is made up of

two plas-

tic

rollers

(l

and 2l

with a clutch felt in betw€€n.

The ldler

is rot^titg the

plastic

mUel

(2)

under. Therefore, the tape-

winding friction is adjust€d by

the

slipping

of the felt

to

enabl€ rated

winding of the tap€.

on the other ha d, the S*pfb

Reel Sbtndle

IHI

h^s a

Blake

lo e/

lEl

hwg on the Plastic

Roll€r

{4)

under

which

provides

app.opriate back tension by

the .lutch fet slipp-

ing

to the rotation ofthe Pull€y

(3)above.

To prevent

accidental er^sure, the Record lnterloch

But-

to,

(F)

mut be depressed

before the RECORD,

PLAY-

BACK

knob can be moved

to the

"REC"

position.

The

Safet! dnice

lclls

depressed to ente.

the record mode

(See

Fisures 2 and

3)

ffi

\

ir

Slipping Rotation

Fig. 2

-6-

Loading...

Loading...