CAUTION

OBSERVERA

ATTENTION

VOORZICHTIG

The heating system comes installed with glycol heating

uid. If the uid level is to low you must ll the system to

the right level before operating the heating system.

Your warranty may be voided and the heating system

may be damaged if you attempt to start it with little or

no glycol heating uid.

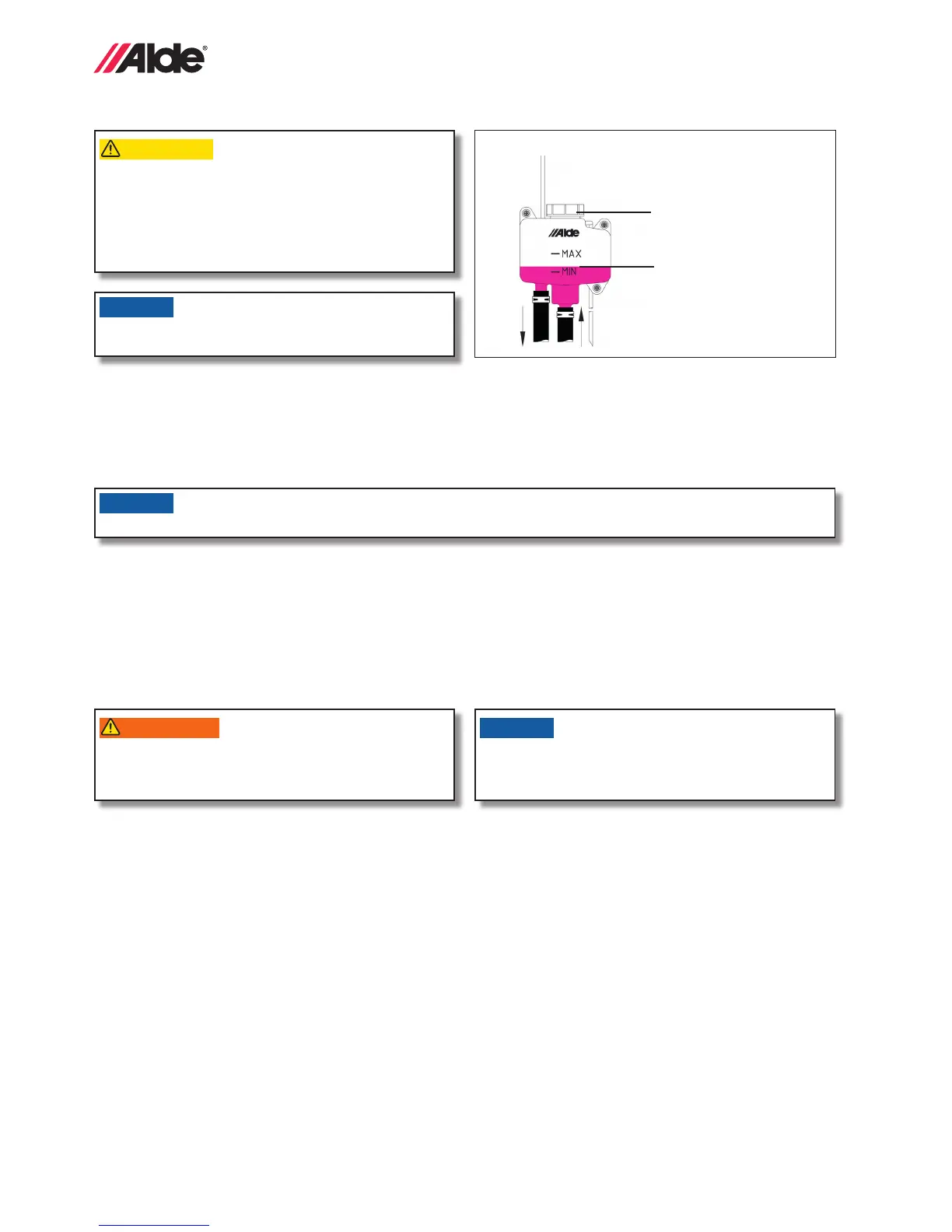

Fluid level in a cold

heating system

Do not mix different types of glycol; this can lead to coagulation

of the glycol uid.

Figure 8. Fluid level of heating system

1:11 GLYCOL HEATING FLUID

The heating system must be lled with a uid mixture consisting of distilled water and ethylene glycol. For best re-

sults, use high-quality ready-mixed ethylene glycol (with inhibitors) intended for use in aluminium heating systems.

The proportions when using concentrated ethylene glycol are 60% distilled water, or water that is free of salts, and

40% ethylene glycol. If the heating system will be exposed to temperatures below -25°C, the ethylene glycol content

has to be increased, however, do not exceed 50%. The ethylene glycol mixture has to be changed every other year,

since properties such as corrosion protection, deteriorate over time. If Alde Premium Antifreeze is used, the interval for

changing the mixture can be extended to max 5 years under normal operating conditions.

The ethylene glycol system is topped up in the expansion tank. Either manually or using Alde’s top-up pump, which

both lls and vents the system. During manual lling, pour the ethylene glycol mixture slowly into the expansion tank.

When the heating system is cold, the level should be approx. 1 cm above the MIN line, see Figure 8. Bleed the sys-

tem. Top up with more uid if the level falls during bleeding. In newly lled heating systems, bleed at regular intervals,

see the section “1:12 lling the heating system with glycol uid”.

The glycol content should be checked at the expansion tank using a pH tester before topping up with new liquid to

help ensure that the concentration of glycol in the mixture is not too high.

If the uid level falls for reasons other than evaporation, please check all joints, drain cocks and bleeder screws for

leakage, including the bleeder located at the end of the convector.

WARNING

VARNING

AVERTISSEMENT

WARNUNG

ADVARSEL

VAROITUS

ADVERTENCIA

AVVERTENZA

WAARSCHUWING

POISONING HAZARD

Be sure to thoroughly clean up any puddles of leaked

glycol. Rinse the area with water and wipe up the ex-

cess to prevent accidental ingestion by children or pets.

The glycol mixture should be changed every second

year to help ensure maximum corrosion inhibitor

effectiveness

1:12 FILLING THE HEATING SYSTEM WITH GLYCOL FLUID

Fill the heating system through the expansion tank, either manually or using the Alde lling pump, which both tops up

and bleeds the system. To purchase a lling pump, contact your Alde dealer. For manual lling, remove the nut

(Figure 8) from the expansion tank. Slowly pour the glycol mixture into the expansion tank , the level should be approx.

1 cm above the MIN line, see Figure 8. Bleed the system. Top up with more uid if the level falls during bleeding. In

newly lled heating systems, bleed at regular intervals.

Omitting to change the uid can result in frost damage, corrosion, bacterial growth and/or overheating.

Nut

Never open the bleeder screws while the pump is

running, because this will induce air into the system.

Figure 9. Automatic Air bleeder

Be sure that the heating system has been thoroughly

bled. If this is not the case, there may be a risk of over-

heating.

Never use full electric or gas capacity before the sys-

tem has been thoroughly bled. There may be a risk of

overheating.

WARNING

VARNING

AVERTISSEMENT

WARNUNG

ADVARSEL

VAROITUS

ADVERTENCIA

AVVERTENZA

WAARSCHUWING

SCALDING HAZARD

Remember, the glycol heating uid may be hot.

1:13 BLEEDING THE SYSTEM

Depending on how the pipes have been tted, air pockets may form when the system is lled with ethylene glycol uid.

If the pipes only warm up a metre or so from the boiler, even though the circulation pump is operating, this is a symp-

tom of air trapped in the system.

In newly lled heating system, small air bubbles can form in the expansion tank, creating a gurgling sound. If the circu-

lation pump is stopped for a few seconds, the bubbles will usually disappear; however, if the problem persists, bleed

the heating system to remedy the problem.

Bleed as follows:

1. The boiler has to be switched off.

2. If a bleed screw is tted to the outgoing pipe of the boiler, open this bleed screw and leave it open until uid starts

coming out. Then, go to point 4.

3. If the boiler is equipped with an automatic air vent, bleeding the boiler takes place automatically. Start the boiler

and circulate the uid in the system until it is vented, top-up with uid, if needed, according to point 5. If this

doesn’t help, switch off the boiler and go to point 4.

4. Open the other bleed screws in the system, one by one. Leave the bleed screws open until ethylene glycol uid

starts coming out of them, and then close them.

5. Check the uid level. Top-up if the level has fallen during venting, the uid level in the expansion tank has to be

approx. 1 cm above the min line in a cold heating system.

6. Start the boiler and let it run for a while. Feel if the pipes and radiators are heating up around the vehicle.

If this does not help, use an Alde lling pump.

• PERSISTENT AIR LOCK

If air lock persists, try the following:

Single-axle trailers:

1. Stop the circulation pump.

2. Lower the front of the trailer as far as possible. Leave it in this position for a few minutes to allow the air to travel

upward in the heating system.

3. Open the bleeder screw at the highest point. Leave it open until it discharges glycol uid.

4. Raise the front of the trailer as far as possible and repeat the procedure in this position.

5. Position the trailer horizontally and start the circulation pump.

6. Check that the pipes and convector’s around the vehicle are heating up.

Motor-home or twin-axle trailers:

The easiest way to bleed the heating system is to place the vehicle on a sloping surface or to raise one end of the

vehicle using a jack. Bleed the heating system as described above. Alternatively, the heating system can be bled using

the approved lling pump. To obtain a pump, contact your Alde dealer.

Loading...

Loading...