11

Ordering spare parts

- Contact the Sales Department.

- Order from the Spare Parts List.

Recommended spare parts: Service kits (see Spare Parts List).

Valve lip seal Valve bearing

Preventive maintenance Replace after 12 months Replace when replacing the

lip seal

Maintenance after leakage Replace by the end of the day Replace when replacing the

(leakage normally starts slowly) lip seal

Adjusted maintenance - Regular inspection for leakage Replace when replacing the

and smooth operation lip seal

- Keep a record of the valve

- Use the statistics for planning

of inspections

Replace after leakage

Lubrication Before fitting None

Silicone grease or silicone oil

1

2

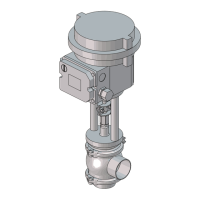

- Never service the valve when it is hot.

- Never service the valve with valve and

pipelines under pressure.

Maintain the valve carefully.

Study the instructions carefully and pay special atten-

tion to the warnings!

Always keep spare lip seals and guide rings in stock.

- Always read the technical data

thoroughly (See page 14).

- Always release compressed air after

use.

- Always disconnect the electrical con-

nection before service.

CAUTION!

The I/P-converter of the actuator is adjusted be-

fore delivery and must never be opened.

NOTE!

All scrap must be stored/disposed of in accord-

ance with current rules/directives.

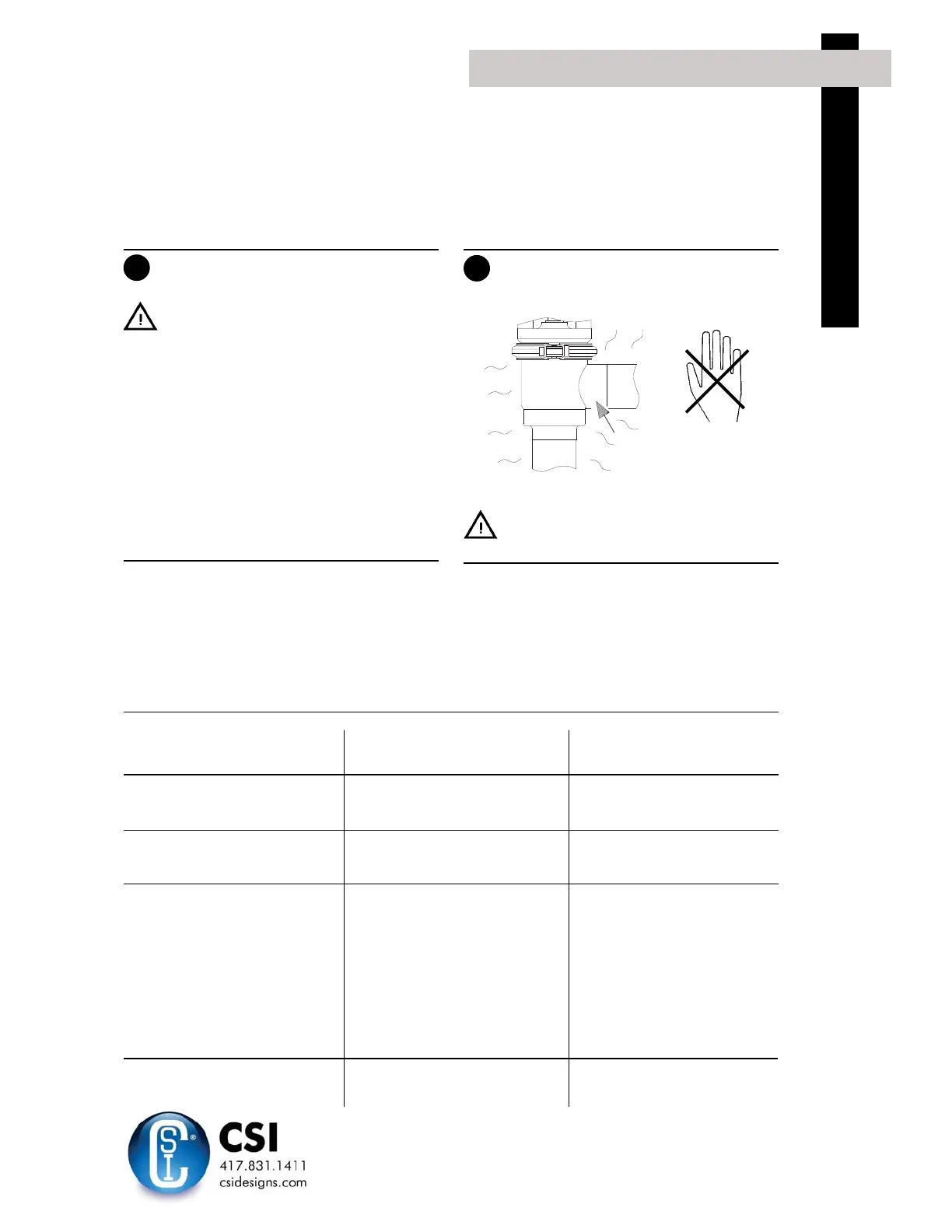

1. General maintenance

Maintenance

Burning

danger!

Atmospheric

pressure re-

quired!

Loading...

Loading...