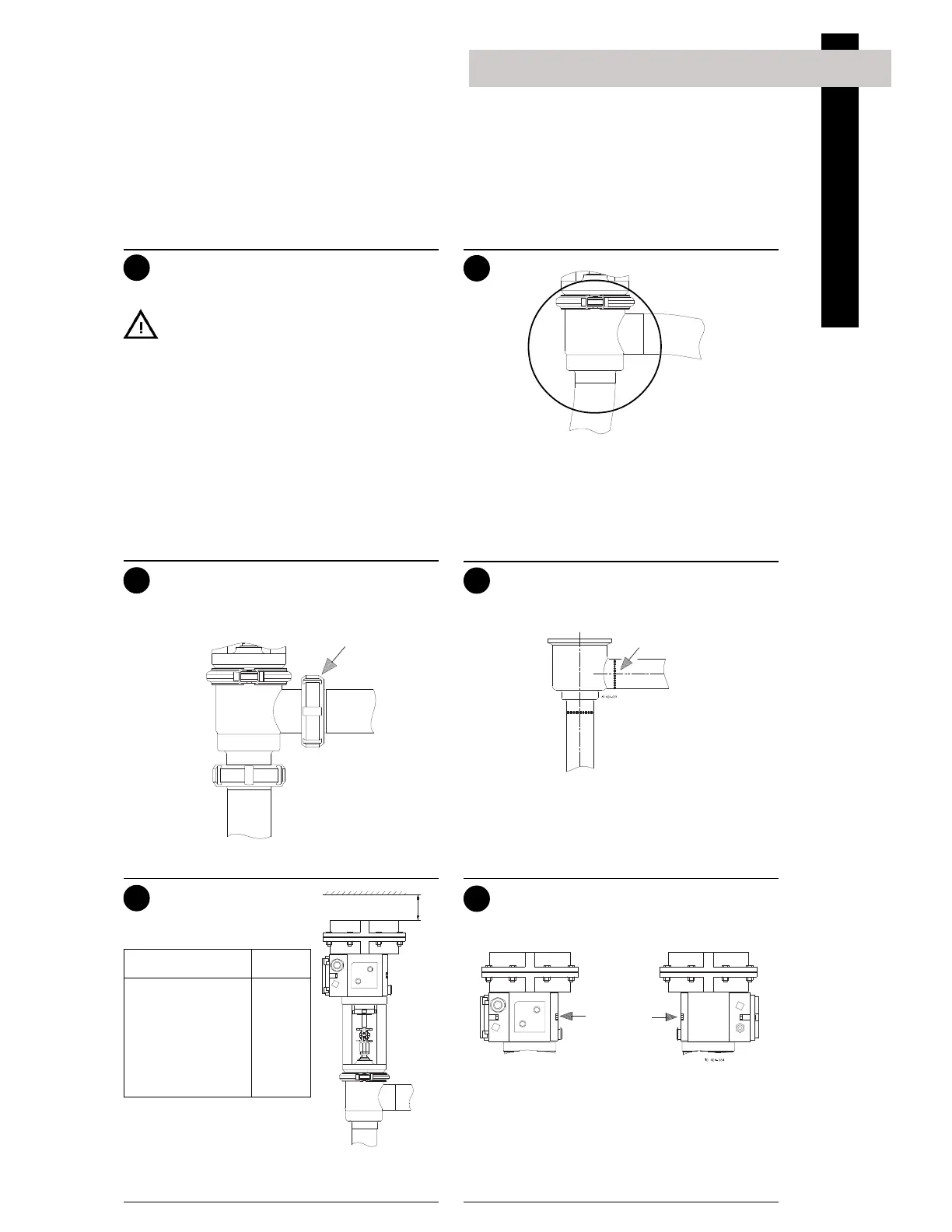

5

Dimension A (mm)

38mm/DN40 100

51mm/DN50 105

63.5mm/DN65 130

76mm/DN80 145

101.6mm/DN100 180

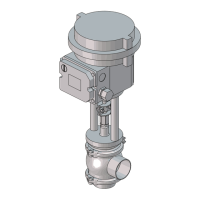

1

3

5

Remember seal rings!

4

2

6

Weld carefully!

Installation

Study the instructions carefully and pay special

attention to the warnings!

The valve has welding ends as standard but can also

be supplied with fittings.

2. Installation

Avoid stressing the valve.

Pay special attention to:

- Vibrations.

- Thermal expansion of the tubes.

- Excessive welding.

- Overloading of the pipelines.

Fittings:

Ensure that the connections are tight.

Welding:

1. Remove the internal valve parts in accor-

dance with instruction 1 on page 12.

2. Weld the valve into the pipelines.

3. Assemble the valve in accordance with in-

struction 5 on page 13.

Welding into a manifold:

Maintain the minimum clearance (A) so that the

actuator can be removed.

Electrical connection:

1. Remove the black cover from the actuator.

2. Fit the cable through the cable gland and

connect it to the terminal strip. Ensure

correct polarity (11 = +,12 = -)!

3. Tighten the cable gland and refit the cover.

- Always read the technical data

thoroughly (See page 14).

- Always release compressed air after

use.

CAUTION!

- Always let the valve be electrically connected

by authorized personnel.

- The I/P-converter of the actuator is adjusted

before delivery and must never be opened.

NOTE!

We cannot be held responsible for incorrect

installation.

Risk of damage!

A

Cover for

electrical

connection

Loading...

Loading...