4Operation

The valve is designed for cleaning in place (CIP). CIP = Cleaning In Place.

Study the instructions carefully and pay special attention to the warnings!

NaOH = Caustic Soda. HNO

3

= Nitric acid.

Internal leakage in the valve is externally visible by means of the leakage outlet.

Step 4

Examples of cleani

ng agents:

Use clean water, free from chlorides.

1. 1% by weight NaOH at 70

o

C (158°F) . 2. 0.5% by weight HNO

3

at 70

o

C(158

°

F).

1kg(2.2lb)

NaOH

+

100l(26.4gal)

water

=

Cleaning agent.

0.7 l (0.2 gal)

53% HNO

3

+

100 l (26.4 gal)

water

=

Cleaning

agent.

2.2 l (0.6 gal)

33%NaOH

+

100l(26.4gal)

water

=

Cleaning agent.

Step 5

1. Avoid excessive concentration of the cleaning agent

=> Dose gradually!

2. Adjust the cleaning flow to the process.

Milk sterilization/viscous liquids

=> Increase the cleaning flow!

Step 6

Valve pneumatic operation during in-place cleaning

Each valve seat shall be lifted during the length of the cleaning cycle.

Seat lift durations shall not exceed 10 seconds.

These pneumatic functions include:

1. Upper va

lve seat lift (takes place during cleaning of upper valve body)

2. Lower va

lve seat push (takes place during cleaning of lower valve body)

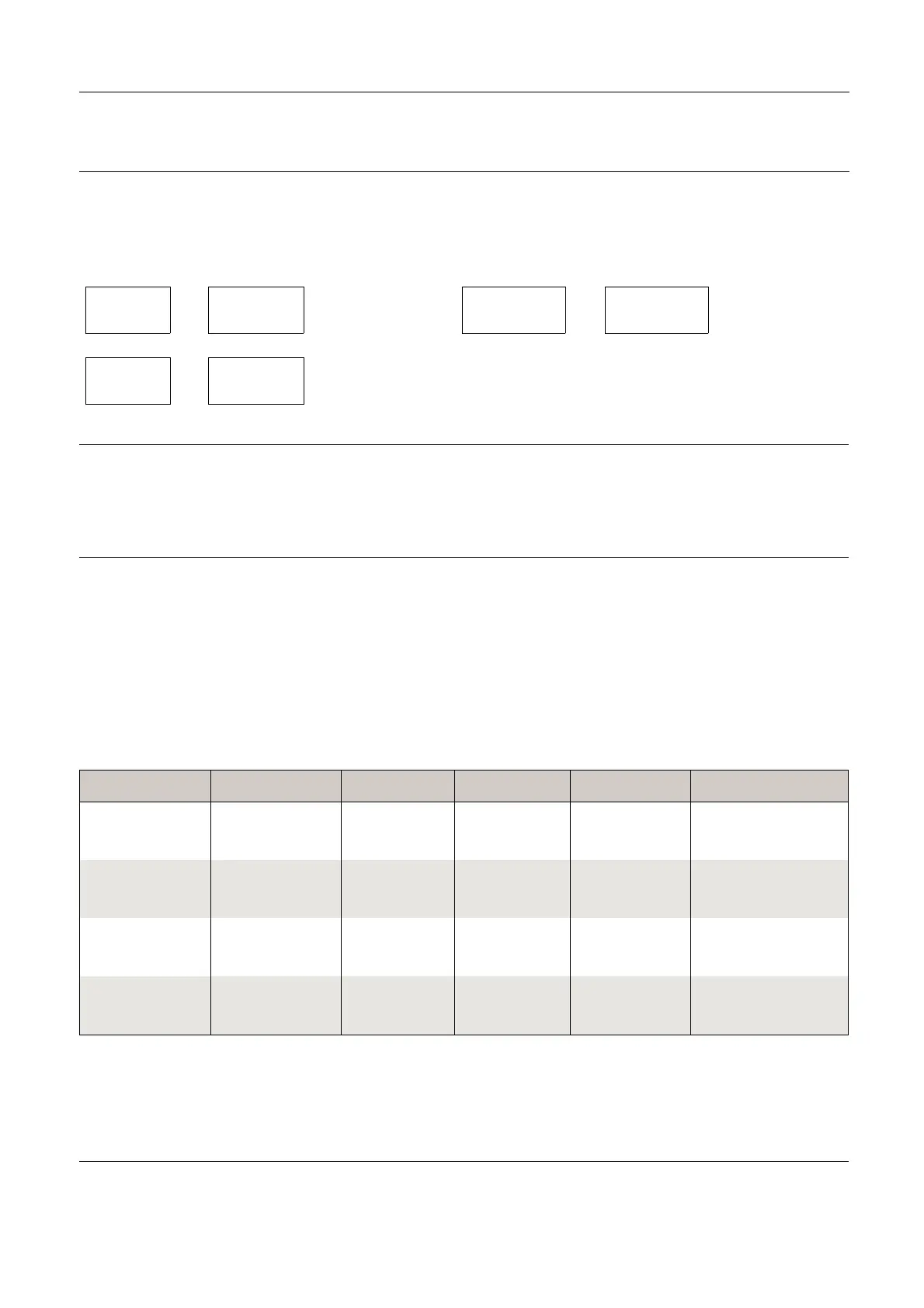

The following chart presents an overview of these functions together with the recommended time durations at 21psi (1.5 bar) CIP

pressu

re. It is recommended to do seat lift/push in the middle of each step in the CIP sequence.

CIP event @ length

Valve function

Valve

solenoid no.

Solenoid

mode

Actual

opening

time

Number of lifts/push

in each CIP step

Upper s

eat lift

3Energi

zed

*0.5 se

c

3

Lower seat lift 2 Energized *0.5 sec 3

Spira

lClean vent

--

*0.5 s

ec

3

Warm pre-rinse @

3minutes

OD cleaning

--

*5 sec 2

Uppe

r seat lift

3Ener

gized

*0.5

sec

3

Lower seat lift 2 Energized *0.5 sec 3

Spir

alClean vent

--

*0.5

sec

3

Hot alkaline wash

@ 10 minutes

OD cleaning

--

*5 sec 2

Upp

er seat lift

3Ene

rgized

*0.

5sec

3

Lower seat lift 2 Energized *0.5 sec 3

Sp

iralClean vent

--

*0.

5sec

3

Cold post wash @

3minutes

OD cleaning

--

*5 sec 2

Up

per seat lift

3En

ergized

*0

.5 sec

3

Lower seat lift 2 Energized *0.5 sec 3

S

piralClean vent

--

*

0.5 sec

3

Cold acidified rinse

@3minutes

OD cleaning

--

*5 sec 2

*Time stated is the actual opening time for the valve. Programmed duration is depended on the access to compressed air and response

time from PLC.

Variations caused by compressed air are typically:

- Long compressed air supply hoses.

- Small ID on air supply hoses.

- Limited availability of compressed air.

20

Loading...

Loading...