8

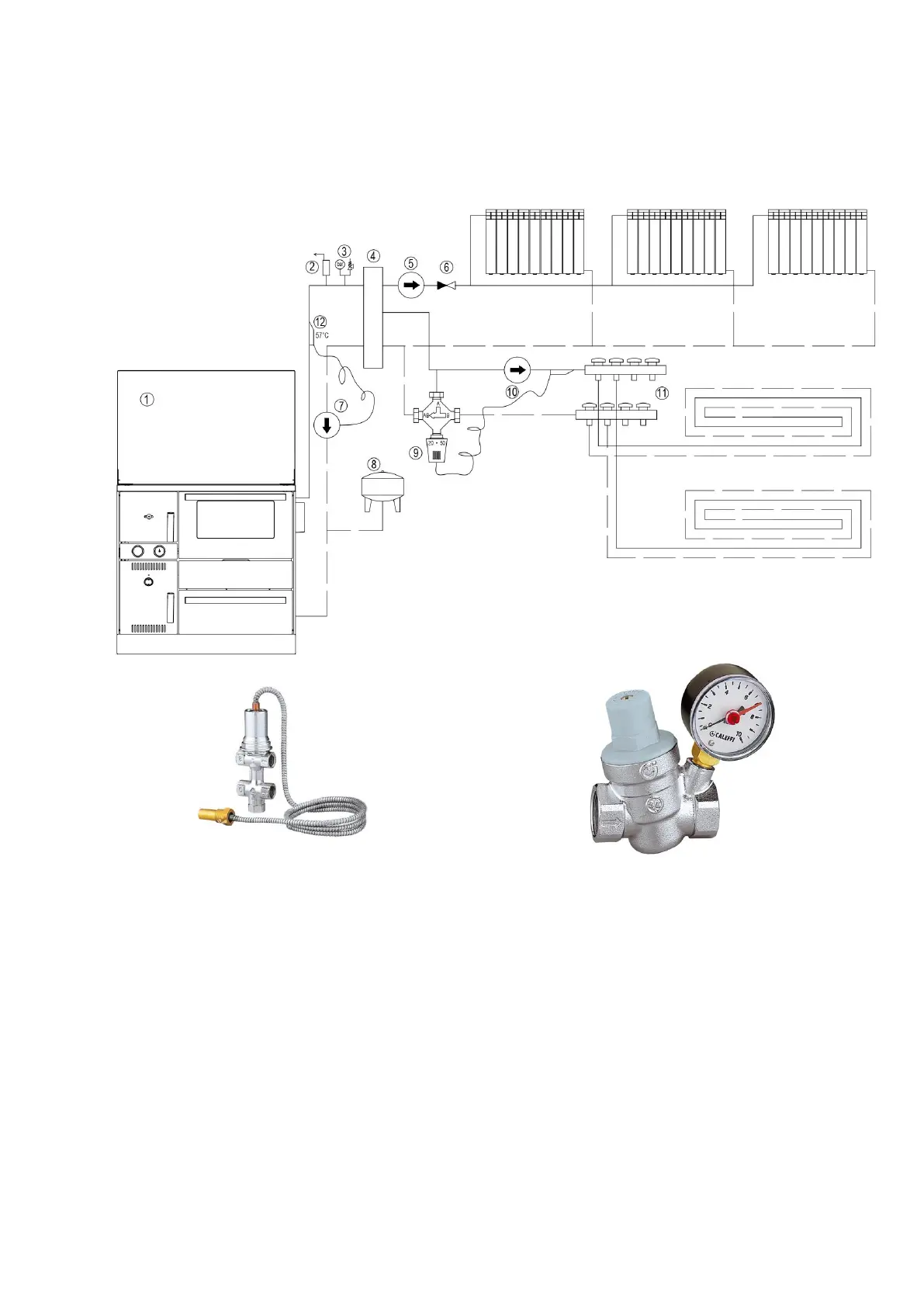

Scheme of the hydraulic installation of a solid fuel (radiator and floor heating)

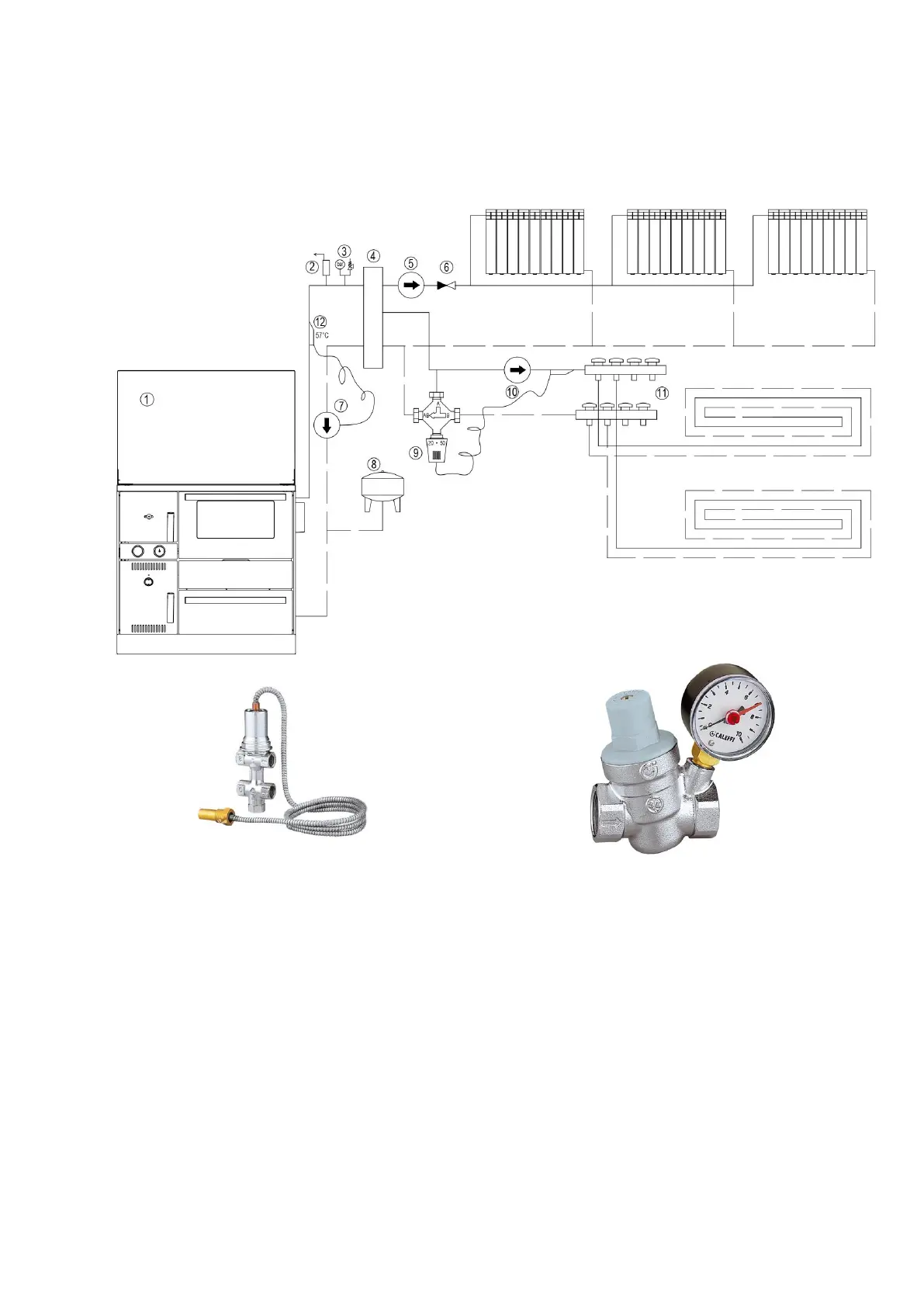

Figure 7a Figure 7b

- It is desirable to insert a pump R1" for more speed whose flow capacity is always appropriate for the current need of the

system. Directly in front and behind the pump, install shut-off valves so that displacement of the pump could be performed for

repairs, changes etc., without releasing water.

- Mount a tap for the filling and draining the system at the lowest system point.

- Before commissioning the system should be filled with water as follows:

a) If the system is open, fill the system through the tap for filling and draining until water starts to leak from the overflow

pipe of the expansion vessel,

b) If the system is closed, the system pressure (working pressure) should be 11,5 bar.

In both cases, fill the system slowly so that air can come out through the air releasing valves. If the valves do not open

themselves, they should be manually open until water starts to leak, than close them.

- The water from the heating system should not be drained in summer neither since it protects the internal side of the system

from spreading oxidation (corrosion).

- If you don’t use the boiler for a longer period in winter, and there is not antifreeze asset in the system, it is best to drain the

water from the system. At the same time open the valves on the radiators, the combined valves and the other shut-off

elements in the system.

- Fire must not be kindled if the water in the boiler is frozen, neither if there is not enough water in the boiler.

9. COMMISSIONING AND STOKING

Before stoking, the entire system for floor (central) heating should be filled with water, well vented and the solid fuel should

be properly connected to the flue as explained in the previous paragraphs.

Legend:

1. Solid fuel

2. Auto Air Vent

3. Safety valve 3 bar

4. Hydraulic crossover

5. Circulation pump

6. Non-return valve

7. Circulation pump

8. Closed expansion vessel

9. Three-way mixing valve with fitting thermostat

10. Circulation pump

11. Underfloor heating separator

12. Contact thermostat

Note: - It is mandatory to install a thermal discharge valve with thermal

protection, the so-called. thermal fuse in accordance with the

recommendations from the technical instructions.

- If only underfloor heating is connected to the stove, be sure to install

a storage tank (BUFFER)

- Install the safety valve directly on the boiler, at the connection

provided, which is described in the instructions.

Loading...

Loading...