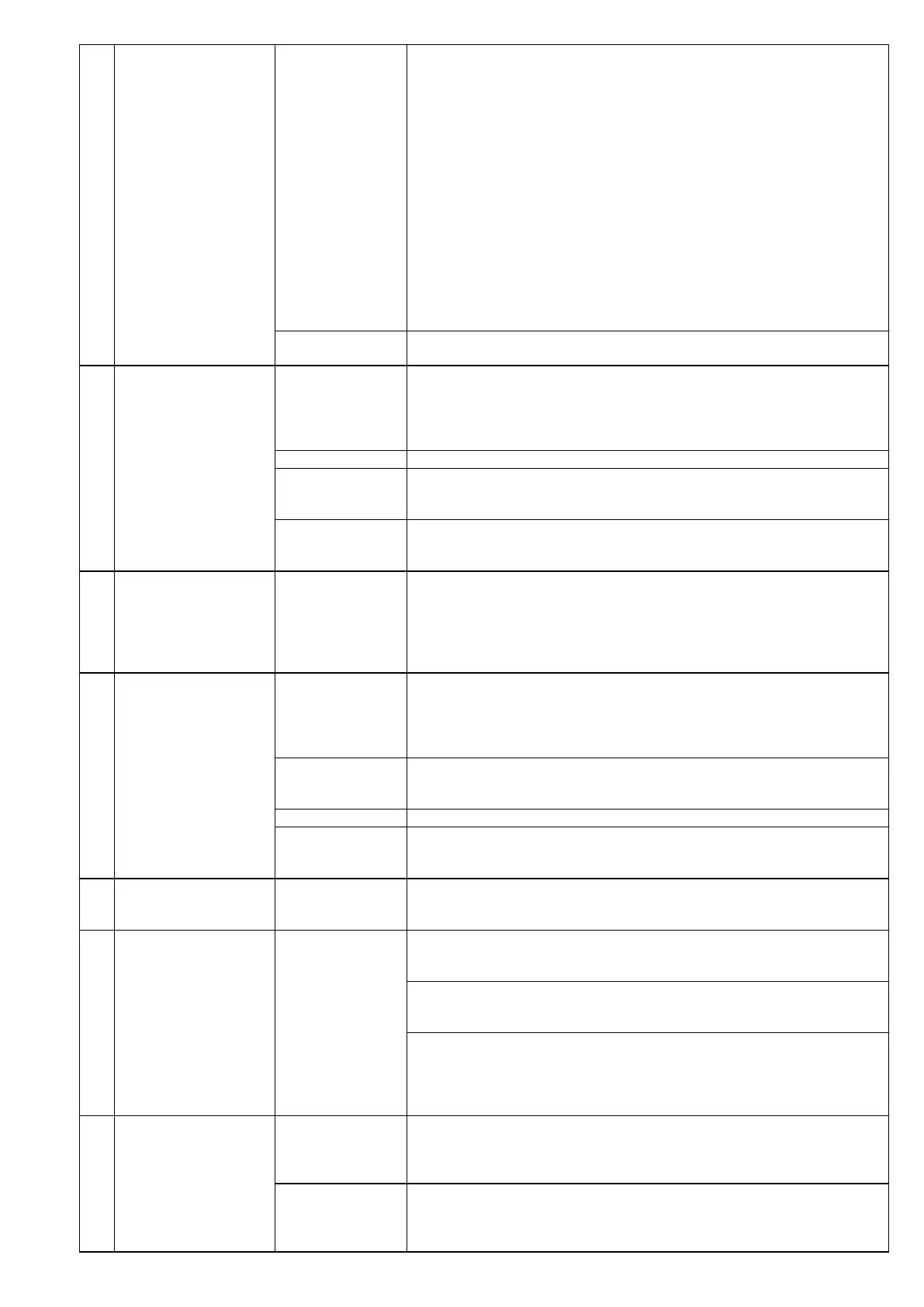

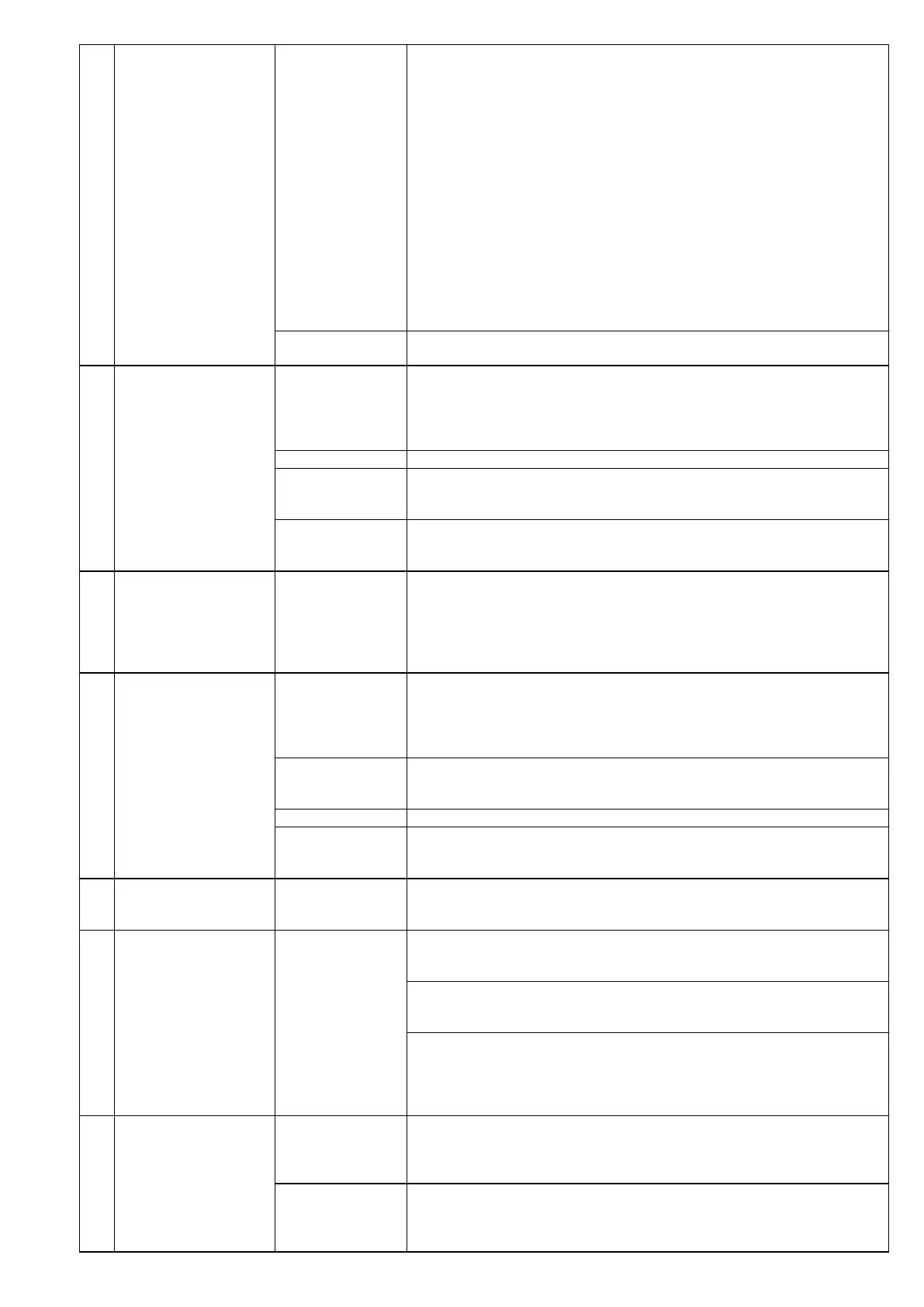

12

Sudden pressure

increase in the

installation while

water temperature

increase

Decreased

pressure in the

expansion vessel

or completely

empty. Remove

the cover or the

vessel valve cap

and release some

air through the

valve. If the

membrane is

destroyed, water

shall leak from

the valve, and if it

is only half-

empty, only air

will come out

If water is leaking from the valve, replace the expansion vessel.

If only air comes out from the valve, remove the installation vessel and

pump it. The pressure in the vessel must be equal to or greater than

height difference of the highest and lowest installation point. Example:

For height difference of 5m. the pressure is Pmin.0,5 bar.

Perform venting of the installation

The circulation pump

does not switch on or

blow a fuse

No power on the

electrical

connection.

Loose

connectors.

Check and tighten the screws at the connection spots. Check and if

necessary, replace the fuses, eliminate the malfunction of the motor or

installation connection

Before the start of each heating, examine the easy rotor turning. Hot water

deposition may lead to rotor blockage. Turn around the motor shaft with a

wrench until free turning of the rotor is enabled.

The pump is

blocked due to

sediment

Disassemble and clean the pump.

The thermometer or

manometer does not

show the amount of

temperature or water

pressure in the

installation

Thermometer or

manometer failure

Replace the thermometer or manometer

Noise (sounds) from

the eating system

Defective pump.

Great clearance

between the rotor

shaft and

bushings

Reduce pump speed. Replace the pump envelopes or the entire pump

The pump is

functioning at too

high speed

Release air from the heating system

Loose knobs or

some screw on

the solid fuel

The pressure at

the pump suction

part is to low

Increase system pressure or check the expansion vessel.

The solid fuel

overheats, loud noise

(cracking) is heard in

the boiler of the solid

fuel.

Electricity outage

has occurred, the

circulation pump

does not work

and the boiler of

the solid fuel

overheats. There

is a danger of

boiler rupture.

To avoid this occurrence, it is best to have backup battery power supply

of the circulation pump with an inverter.

Installation of a thermal exhaust valve (Fig. 7, pos. 13) is required as

additional security against solid fuel overheating.

If you do not have backup supply of the circulation pump or a thermal

exhaust valve installed, then you should open the bypass valve connected

in parallel with the circulation pump on the pipeline system and remove

embers from the solid fuel.

Cooling thermal fuse

is activated (thermo

valve) because

water temperature

increased over 95C

due to:

This is proper and do not touch anything. When the system is cold,

thermal valve will be closed.

After that, check the pressure in the installation and fill the system to the

required.

- open ashtray

door and no

regulated

combustion

Close the ashtray door and through the knob on the cover of the ashtray

door and thermostat, reduce the water temperature in the system.

Loading...

Loading...