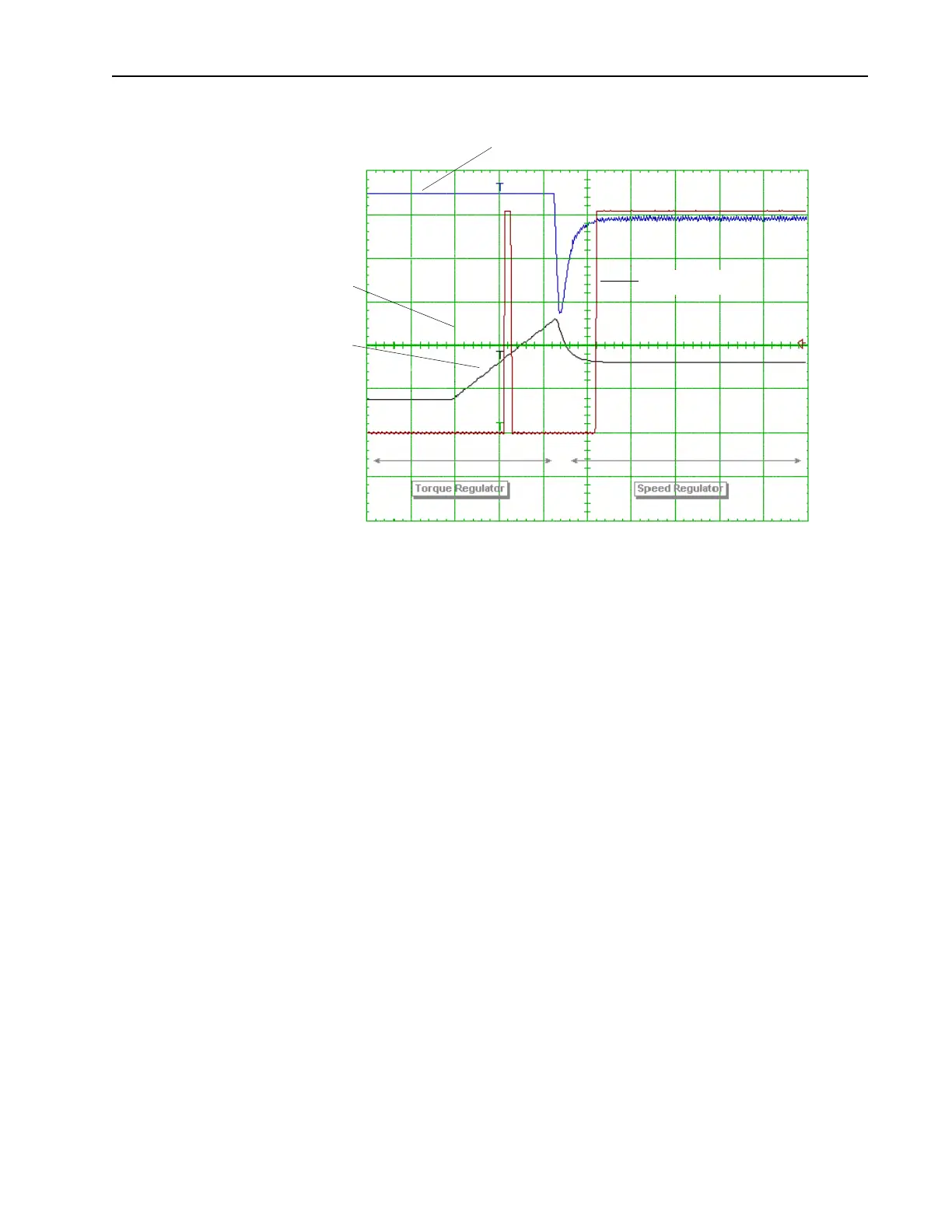

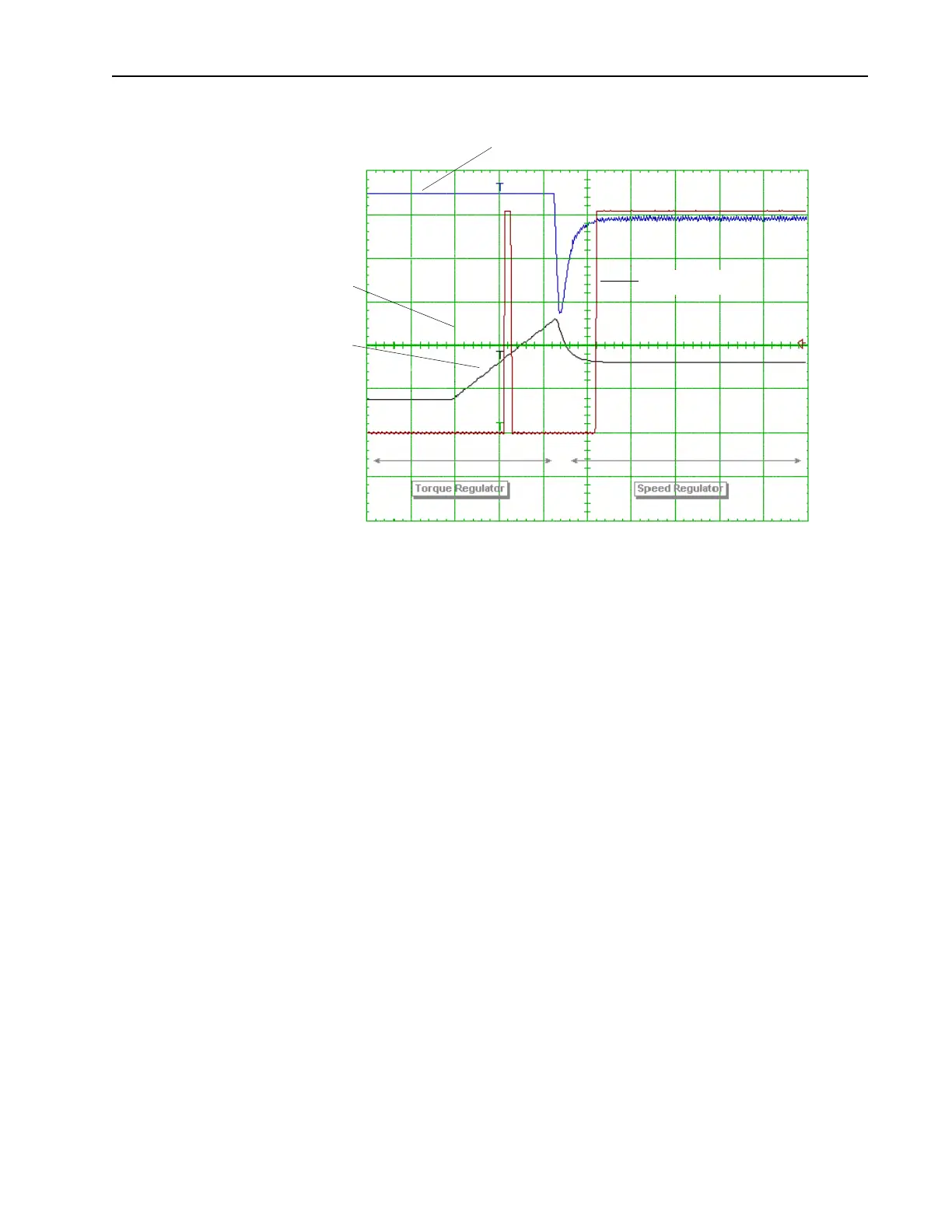

Speed/Torque Select 2-179

Figure 2.38

Sum Mode

Configuring the drive in this mode allows an external torque input to be

summed with the torque command generated by the speed regulator. The

drive requires both a speed reference and a torque reference to be linked.

This mode can be used for applications that have precise speed changes

with critical time constraints. If the torque requirement and timing is known

for a given speed change, then the external torque input can be used to

preload the integrator. The timing of the speed change and the application of

an external torque command change must be coordinated for this mode to

be useful. The sum mode will then work as a feed forward to the torque

regulator.

Zero Torque Mode

Operation in zero torque mode allows the motor to be fully fluxed and ready

to rotate when a speed command or torque command is given. For a cyclical

application where through put is a high priority this mode can be used. The

control logic can select zero torque during the “rest” portion of a machine

cycle instead of stopping the drive. When the cycle start occurs, instead of

issuing a start to the drive, a speed regulate mode can be selected. The drive

will then immediately accelerate the motor without the need for “flux up”

time.

Important: Zero Torque may excessively heat the motor if operated in this

mode for extended periods of time. No load or flux current is

still present when the drive is operating in zero torque mode. A

motor with an extended speed range or separate cooling

methods (blower) may be required.

Internal Torque Command

Load Step (Decrease)

Speed Feedback

308

RPM

At Speed Relay

Loading...

Loading...