2-122 Mounting

Mounting Refer to the Chapter 1 of the correct drive User Manual for mounting

instructions and limitations. As a general rule, drives should be mounted on

a metallic flat surface in the vertical orientation. If other orientations are

being considered, contact the factory for additional data.

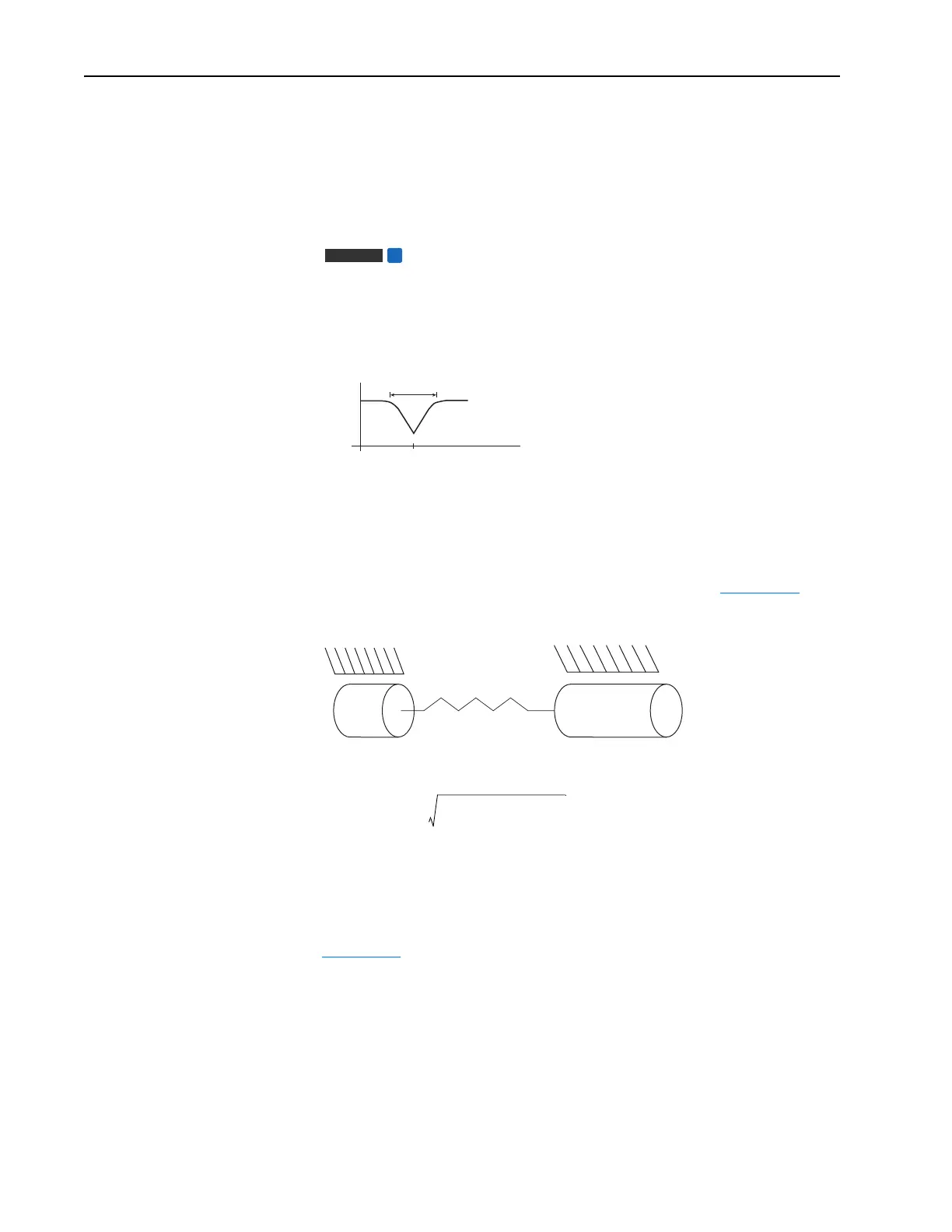

Notch Filter The 700 Vector has a notch filter in the torque reference loop

used to eliminate mechanical resonance created by a gear train. [Notch

Filter Freq] sets the center frequency for the 2 pole notch filter, and [Notch

Filter K] sets the gain.

Figure 2.23 Notch Filter Frequency

Due to the fact that most mechanical frequencies are described in Hertz,

[Notch Filter Freq] and [Notch Filter K] are in Hertz as well. The following

is an example of a notch filter.

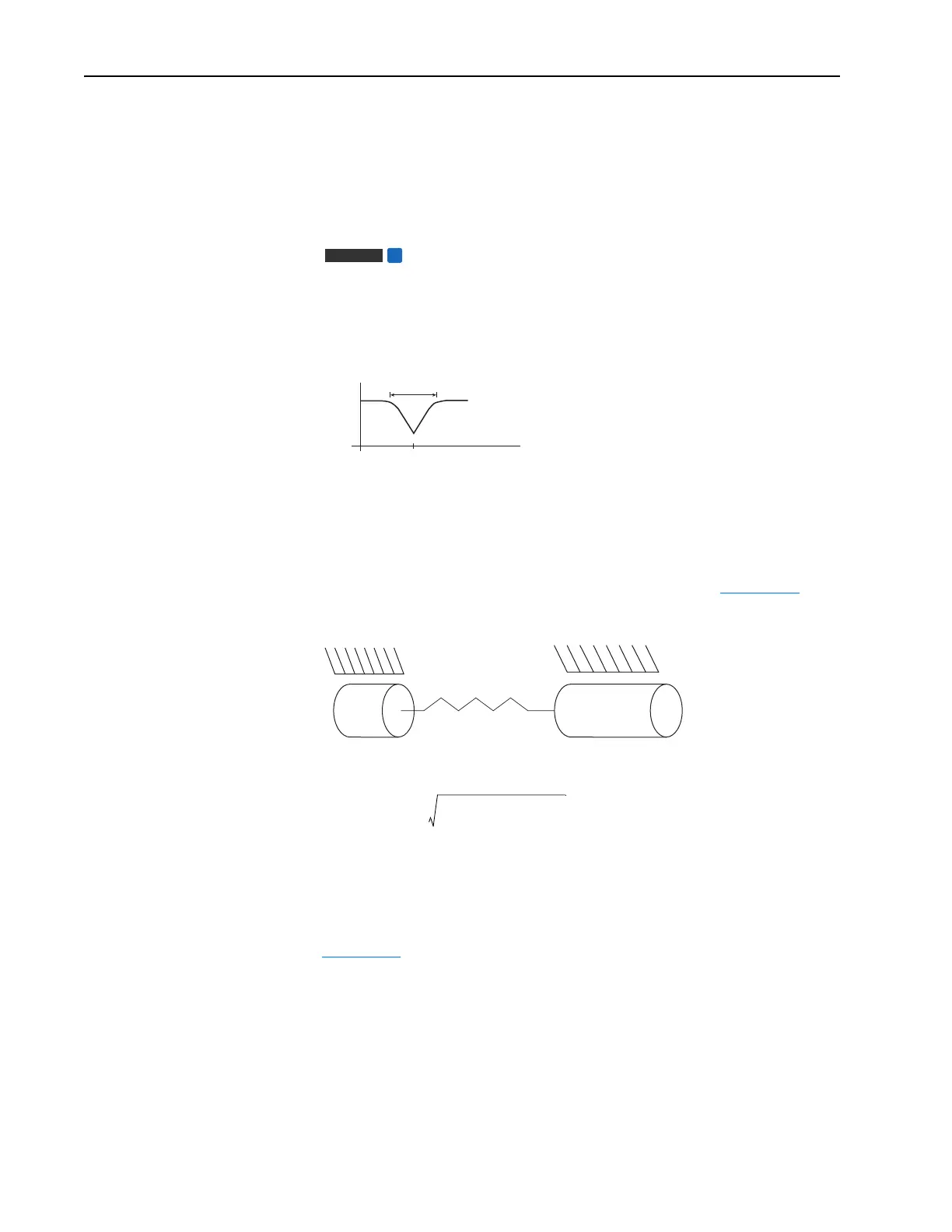

A mechanical gear train consists of two masses (the motor and the load) and

spring (mechanical coupling between the two loads). See Figure 2.24

.

Figure 2.24 Mechanical Gear Train

The resonant frequency is defined by the following equation:

Figure 2.25

shows a two mass system with a resonant frequency of 62

radians/second (9.87 Hz). One Hertz is equal to 2ðπ radians/second.

Vector

FV

Gain

0 db

Hz

Notch Filter Frequency

Notch Filter K

Kspring

BLBm

Jm Jload

Jm is the motor inertia (seconds)

Jload is the load inertia (seconds)

Kspring is the coupling spring constant (rad

2

/sec)

resonance Kspring

Jm Jload+()

Jm Jload×

---------------------------------

=

Loading...

Loading...