Scale Blocks 2-157

Scale Blocks See also Analog Scaling on page 2-12 and page 2-22.

Scale blocks are used to scale a parameter value. [Scalex In

Value] is linked to the parameter that you wish to scale. [Scalex In Hi]

determines the high value for the input to the scale block. [Scalex Out Hi]

determines the corresponding high value for the output of the scale block.

[Scalex In Lo] determines the low value for the input to the scale block.

[Scalex Out Lo] determines the corresponding low value for the output of

the scale block. [Scalex Out Value] is the resulting output of the scale block.

There are (3) ways to use the output of the scale block:

1. A linkable destination parameter can be linked to [Scalex Out Value].

See Example Configuration #1

.

2. [Analog Outx Sel] can be set to:

– 20, “Scale Block1”

– 21, “Scale Block2”

– 22, “Scale Block3”

– 23, “Scale Block4”

Note that when the Analog Outputs are set to use the scale blocks, the

[Scale x Out Hi] and [Scale x Out Lo] parameters are not active. Instead,

[Analog Outx Hi] and [Analog Outx Lo] determine the scaling for the

output of the scale block. See Example Configuration #2

.

3. [PI Reference Sel] and [PI Feedback Sel] can also use the output of the

scale block by setting them to:

– 25, “Scale Block1 Out”

– 26, “Scale Block2 Out”

Note that when [PI Reference Sel] and [PI Feedback Sel] are set to use

the scale blocks, the [Scale x Out Hi] and [Scale x Out Lo] parameters

are not active. Instead, [PI Reference Hi] and [PI Reference Lo], or [PI

Feedback Hi] and [PI Feedback Lo], determine the scaling for the output

of the scale block. See Example Configuration #3

.

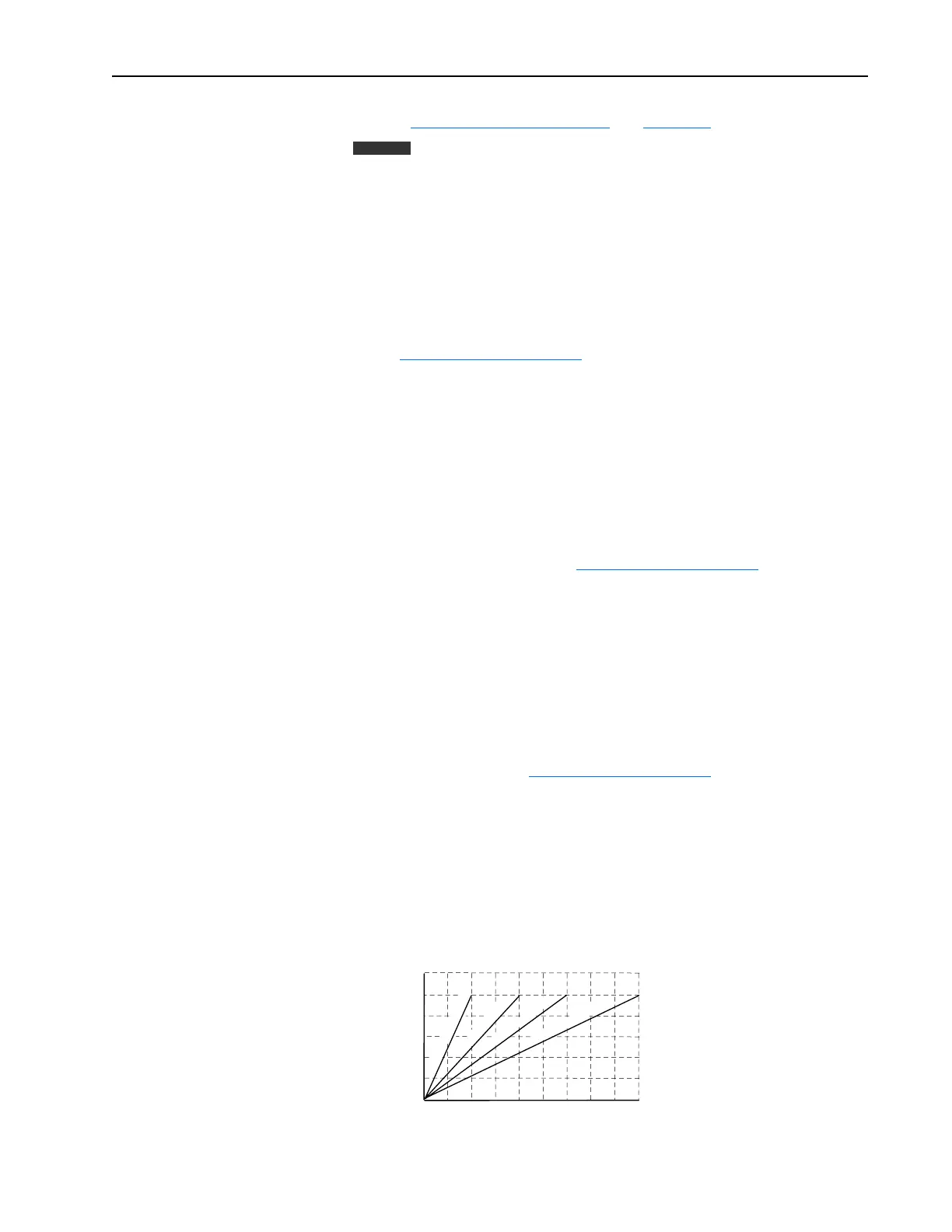

Example Configuration #1

Use the scale blocks to add a speed trim as a percentage of the speed

reference instead of as a percent of full speed. Analog In 2 will be used to

provide a 0-10V DC trim signal. For example, when the commanded speed

is 800 RPM, the maximum trim with 10V DC at Analog In 2 will be 80

RPM. If the commanded speed is 1800 RPM the maximum trim will be 180

RPM.

Vector

Cmd Spd = 400 RPM

Cmd Spd = 800 RPM

Cmd Spd = 1200 RPM

Cmd Spd = 1800 RPM

0

0

2

4

6

8

10

20 40 60 80 100 120 140 180

Preset Speed 1 (RPM)

Scale1 In Value =

Analog In2 Val (Volts)

Loading...

Loading...