2.2 - Diaphragm Pump Operation and

Maintenance (9910 D30)

Proper Maintenance and Operation for Reducer, 9910 D30

Pump and Control Valve

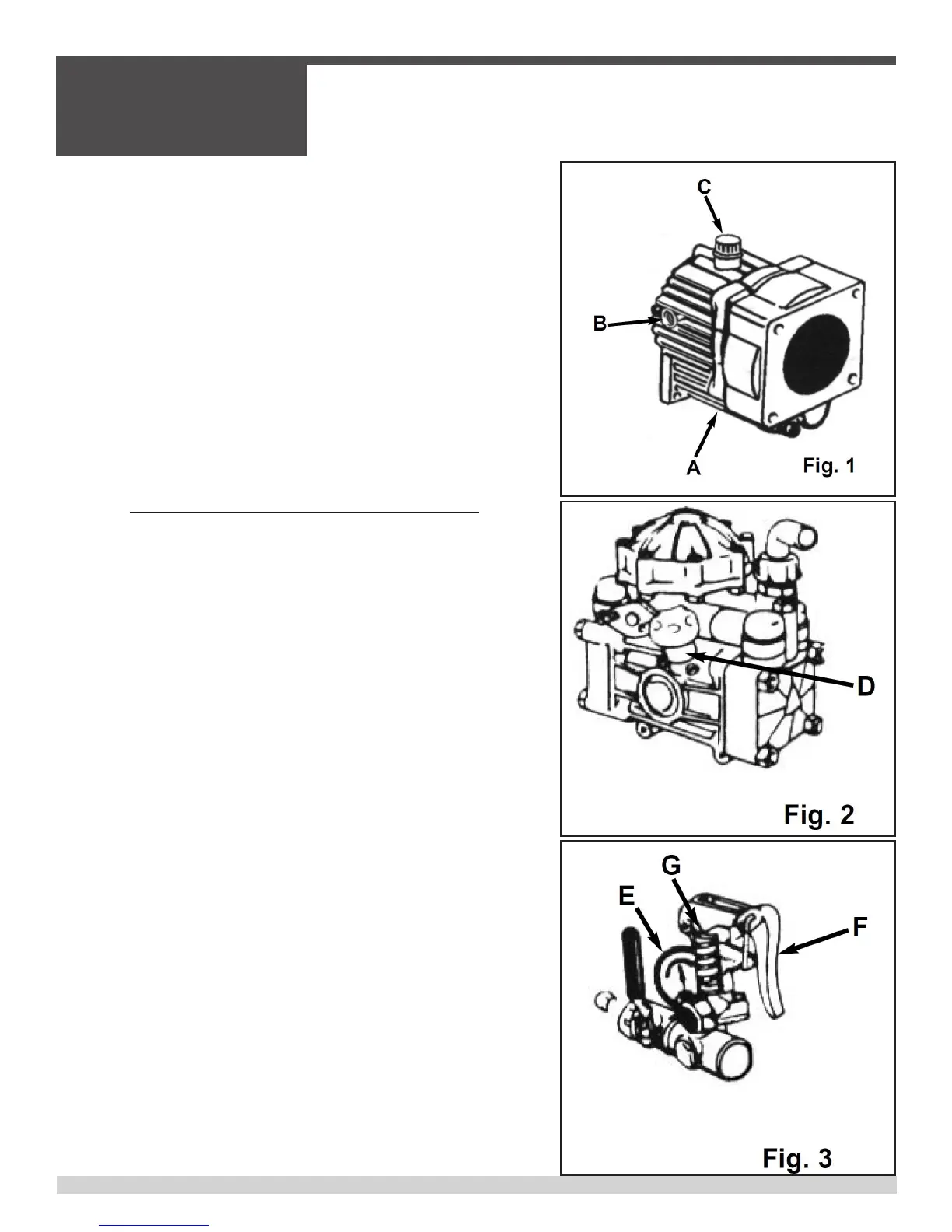

1. When changing oil in the Reducer, remove the drain plug

(A) located on the bottom of the Reducer. (refer to Fig. 1)

After the oil has completely drained, replace drain plug(A)

and tighten. To ll, remove side level plug (B) and vent

plug (C). (refer to Fig. 1) Fill until the gear lube is no higher

than the mark on the dipstick. After proper oil level has

been obtained replace plugs.

USE 90W GEAR LUBE TO FILL GEAR CASE

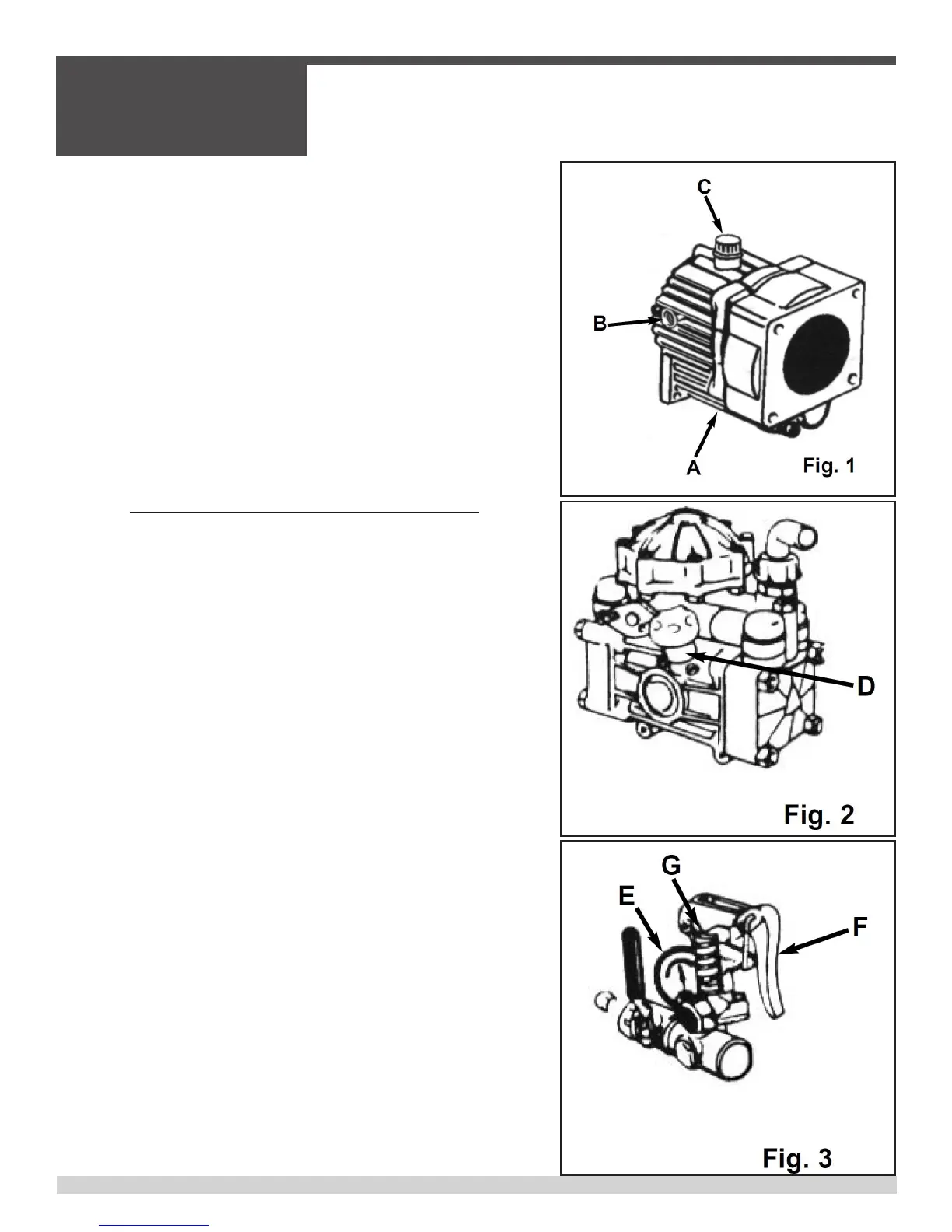

2. Check oil level in pump daily. Be sure oil is halfway up

to the clear oil sight tube (D). If it is not, ll to the correct

level using a high-grade, non-detergent, SAE 30 weight

oil. This will help prolong the pump life. (refer to Fig. 2)

3. Check the charge pressure (E) on the pulsation dampener

before starting the pump. The pressure is checked with a

standard automotive air gauge. The pressure should be at

approximately 20% of the maximum operating pressure.

(refer to Fig. 3)

4. On the pump you can adjust the pressure by clamping the

relief valve adjustment lever (F) down. With the bale hook

in the number one position the pressure is about 100 psi;

number two is about 250 psi; number three is about 450

psi; number four is about 550 psi. These pressures can

be adjusted by using the ne adjustment knob (G) located

on top of the relief valve spring. The ne adjustment knob

can be rotated when the relief valve lever is in the up

position. (refer to Fig. 3)

SECTION 2

OPERATIONS

038479 Page 30

Loading...

Loading...