25

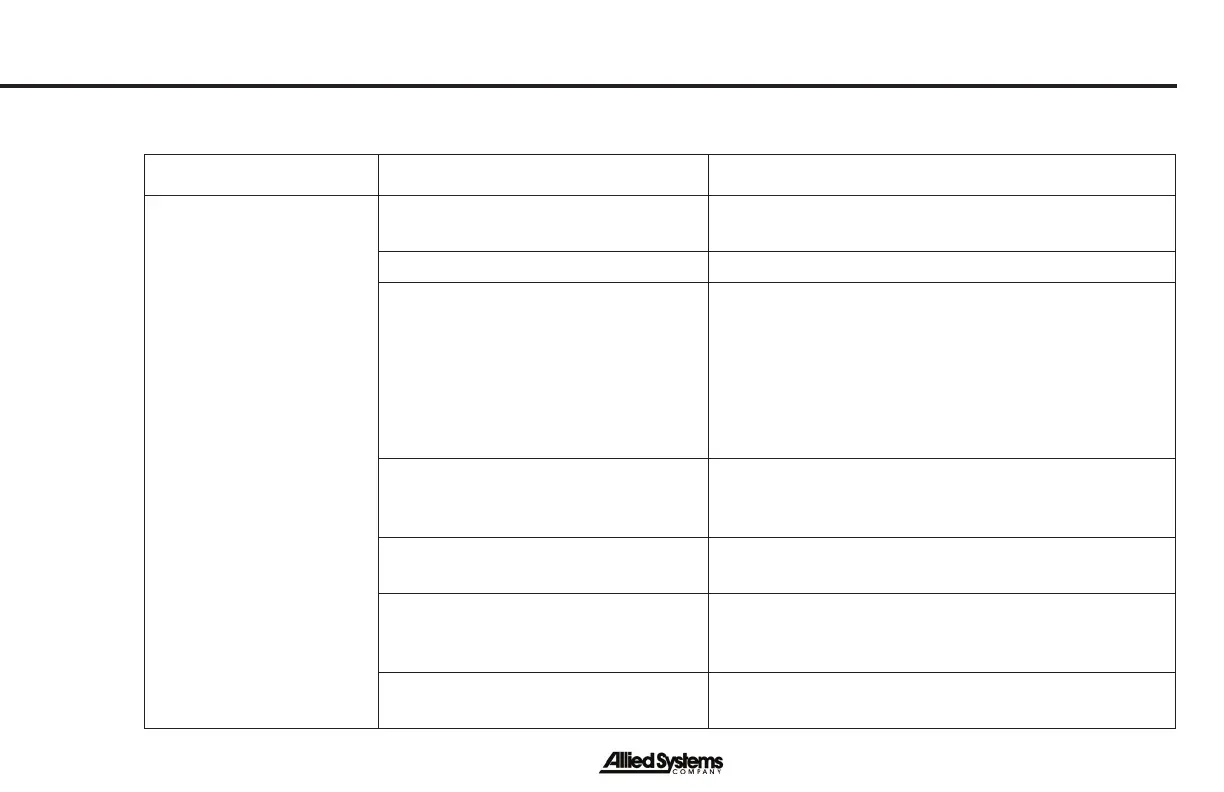

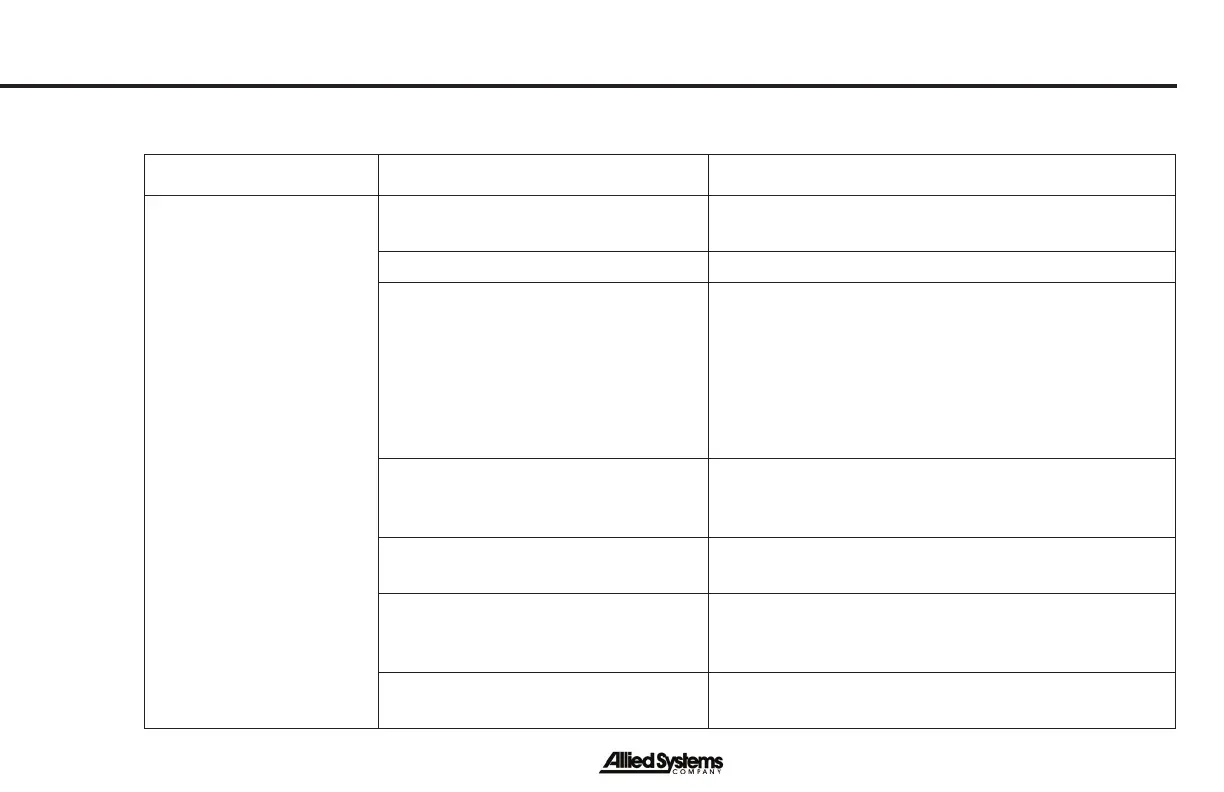

PROBLEM POSSIBLE CAUSE CORRECTION

Low forward or reverse

clutch pressure

Leak in hydraulic system, or loose

hydraulic connections.

Visually inspect winch for leaks, and ensure

hydraulic connections are secure.

Leaky clutch circuit. Perform clutch bleed-down test on clutch circuit.

Broken or worn seal rings on the

bevel gear shaft.

Replace seal rings.

NOTE: A broken seal ring is the most common

cause of a pressure differential between the two

clutches. Check preload on clutch/brake shaft

and adjust it if necessary to prevent additional

breakage of seal rings; refer to Section 4 in

Service Manual.

Damaged bevel gear shaft seal

ring grooves.

Check grooves for taper, scoring and rust. Replace

or rebuild shaft if surfaces between the inner side

of groove and seal ring are not fl at.

Damaged bevel gear shaft bearing

retainers.

Check retainer for grooves. Replace retainer if

defective, or re-sleeve.

Damaged clutch piston, piston

retainer or O-rings.

Check piston and piston retainer cavity for

damage. Always replace both O-rings when clutch

is repaired. Refer to Section 4 in Service Manual.

Reverse pressure hose damaged

by bevel gear.

Remove cover and inspect.

Figure 9 - Troubleshooting Analysis Chart

Operation

(Continued on next page)

Loading...

Loading...