508155-01 Issue 2108 Page 7 of 49

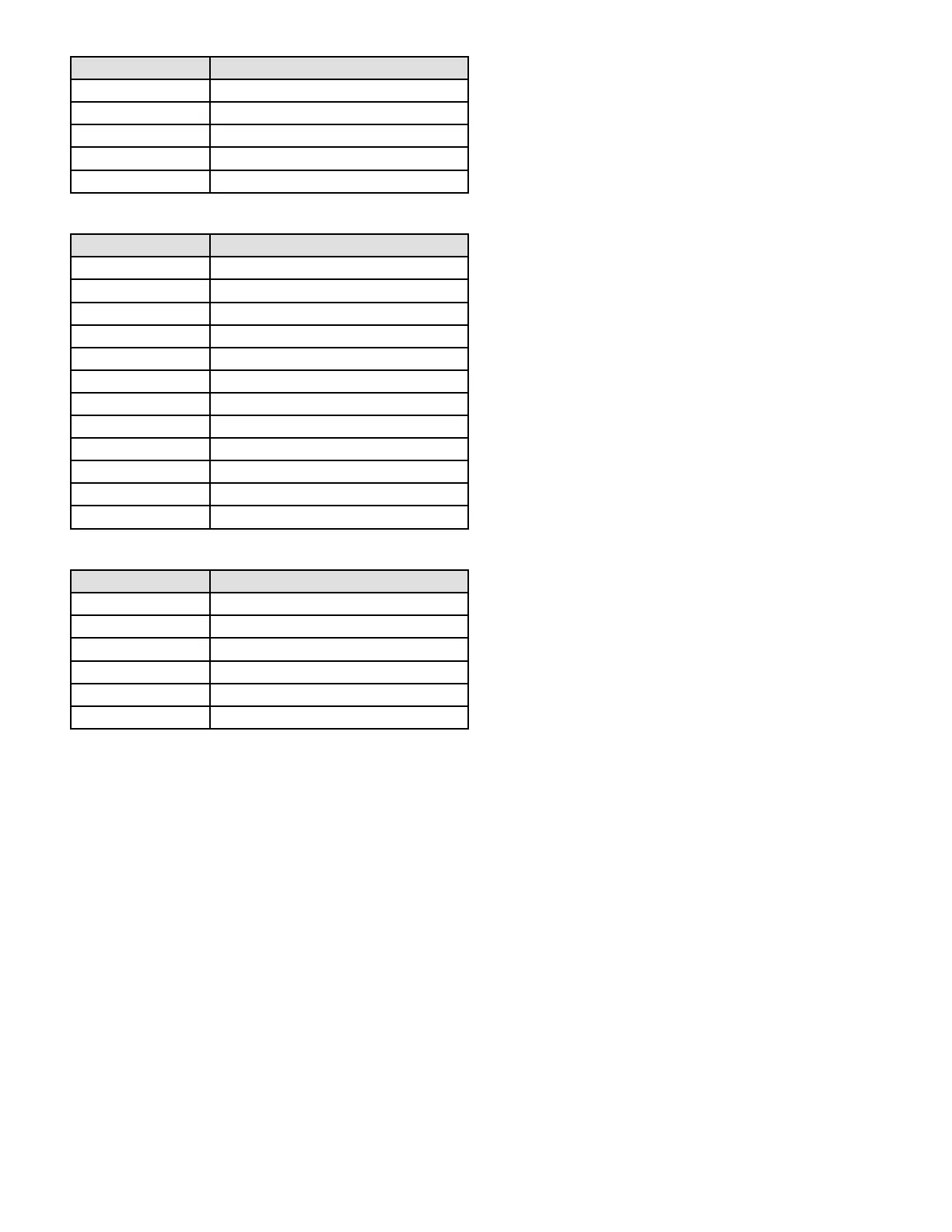

Pin # Function

1 Ignitor

2 Combustion Air Inducer High Speed

3 Combustion Air Inducer Low Speed

4 Combustion Air Inducer Neutral

5 Ignitor Neutral

Table 1. Control 5-Pin Terminal Designation

Pin # Function

1 Gas Valve Second Stage

2 Second Stage Prove Switch

3 Rollout Switch In

4 Ground

5 24V Hot

6 Primary Limit In

7 Gas Valve First Stage

8 Gas Valve Common

9 24V Neutral

10 Ground

11 Rollout Switch Out

12 First Stage Prove Switch

Table 2. Control 12-Pin Terminal Designation

Pin # Function

1 Data Input From Motor

2 Common

3 Not Used

4 Data Output To Motor

5 5 Volt Bias Supply

6 Not Used

Table 3. Control 6-Pin Terminal Designation

Electronic Ignition

At the beginning of the heat cycle the integrated control

monitors the rst stage and second stage combustion air

inducer prove switch. The control will not begin the heating

cycle if the rst stage prove switch is closed (by-passed).

Likewise the integrated control will not begin the second

stage heating cycle if the second stage prove switch is

closed, and will remain in rst stage heat. However, if the

second stage prove switch closes during the rst stage

heat pre-purge, the control will allow second stage heat.

Once the rst stage prove switch is determined to be open,

the combustion air inducer is energized on low (rst stage)

heat speed. When the dierential in the prove switch is

great enough, the prove switch closes and a 15-second

pre-purge begins.

NOTE: During abnormal conditions such as low supply

voltage or low outdoor temperatures and the low re

pressure switch does not close, the combustion air inducer

will switch to high re. After a 15 second pre-purge the

high re pressure switch will close and the unit will begin

operation on high re. After 10 to 20 seconds of high re

operation the unit will switch to low re

After the 15-second pre-purge period, the ignitor warms

up for 20 seconds after which the gas valve opens for a

4-second trial for ignition. The ignitor remains energized

during the trial until ame is sensed. If ignition is not proved

during the 4-second period, the control will try four more

times with an inter purge and warm-up time between trials

of 35 seconds. After a total of ve trials for ignition (including

the initial trial), the control goes into Watchguard-Flame

Failure mode. After a 60-minute reset period, the control

will begin the ignition sequence again.

Two Stage Operation / Thermostat Selection

DIP Switch

The control can be utilized in two modes: SINGLE-STAGE

thermostat or TWO-STAGE thermostat. The thermostat

selection is made using a DIP switch and must be positioned

for the particular application. DIP switch 1, labeled T”STAT

HEAT STAGE is factory-set in the OFF position for use

with a two-stage thermostat. Move the DIP switch to ON

for use with a single stage thermostat.

While in the single-stage thermostat mode, the burners will

always re on rst-stage heat. The combustion air inducer

will operate on low speed and indoor blower will operate on

low heat speed. The unit will switch to second stage heat

after a “recognition period”. DIP switch 2, labeled SECOND

STAGE DELAY, is factory set in the OFF position for a 7

minute recognition period. The switch can be moved to the

ON position for a 12 minute recognition period, after which

time the unit will switch to secondstage heat.

While in the two-stage thermostat mode, the burners will

re on rst-stage heat. The combustion air inducer will

operate on low speed and indoor blower will operate on low

heat speed. The unit will switch to second-stage heat on

call from the indoor thermostat. If there is a simultaneous

call for rst and second stage heat, the unit will re an

rst stage heat and switch to second stage heat after 30

seconds of operation. See Sequence of Operation ow

charts in the back of this manual for more detail.

Loading...

Loading...