508433-01Issue 2345Page 56 of 70

Maintenance

ELECTRICAL SHOCK, FIRE,

OR EXPLOSION HAZARD.

Failure to follow safety warnings exactly could result in

dangerous operation, serious injury, death or property

damage.

Improper servicing could result in dangerous operation,

serious injury, death, or property damage.

Before servicing, disconnect all electrical power to

furnace.

When servicing controls, label all wires prior to

disconnecting. Take care to reconnect wires correctly.

Verify proper operation after servicing.

WARNING

At the beginning of each heating season, system should

be checked as follows by a qualied service technician:

Blower

Check the blower wheel for debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

The blower access panel must be securely in place

when the blower and burners are operating. Gas fumes,

which could contain carbon monoxide, can be drawn

into living space resulting in personal injury or death.

WARNING

Filters

All air lters are installed external to the unit. Filters should

be inspected monthly. Clean or replace the lters when

necessary to ensure proper furnace operation. Table 21

lists recommended lter sizes.

If a high-eciency lter is being installed as part of this

system to ensure better indoor air quality, the lter must

be properly sized. High-eciency lters have a higher

static pressure drop than standard-eciency glass/foam

lters. If the pressure drop is too great, system capacity

and performance may be reduced. The pressure drop

may also cause the limit to trip more frequently during

the winter and the indoor coil to freeze in the summer,

resulting in an increase in the number of service calls.

Before using any lter with this system, check the

specications provided by the lter manufacturer

IMPORTANT

Cabinet Width

Filter Size

Side Return Bottom Return

17-1/2”

16 x 25 x 1 (1)

16 x 25 x 1 (1)

21” 20 x 25 x 1 (1)

24-1/2” 16 x 25 x 1 (2) 24 x 25 x 1 (1)

Table 21.

Exhaust and Air Intake Pipes

Check the exhaust and air intake pipes and all connections

for tightness and to make sure there is no blockage.

NOTE: After any heavy snow, ice or frozen fog event the

furnace vent pipes may become restricted. Always check

the vent system and remove any snow or ice that may be

obstructing the plastic intake or exhaust pipes.

Electrical

Fire Hazard. Use of aluminum wire with this product

may result in a re, causing property damage, severe

injury or death. Use copper wire only with this product.

WARNING

Failure to use properly sized wiring and circuit breaker

may result in property damage. Size wiring and circuit

breaker(s) per Product Specications and unit rating

plate.

CAUTION

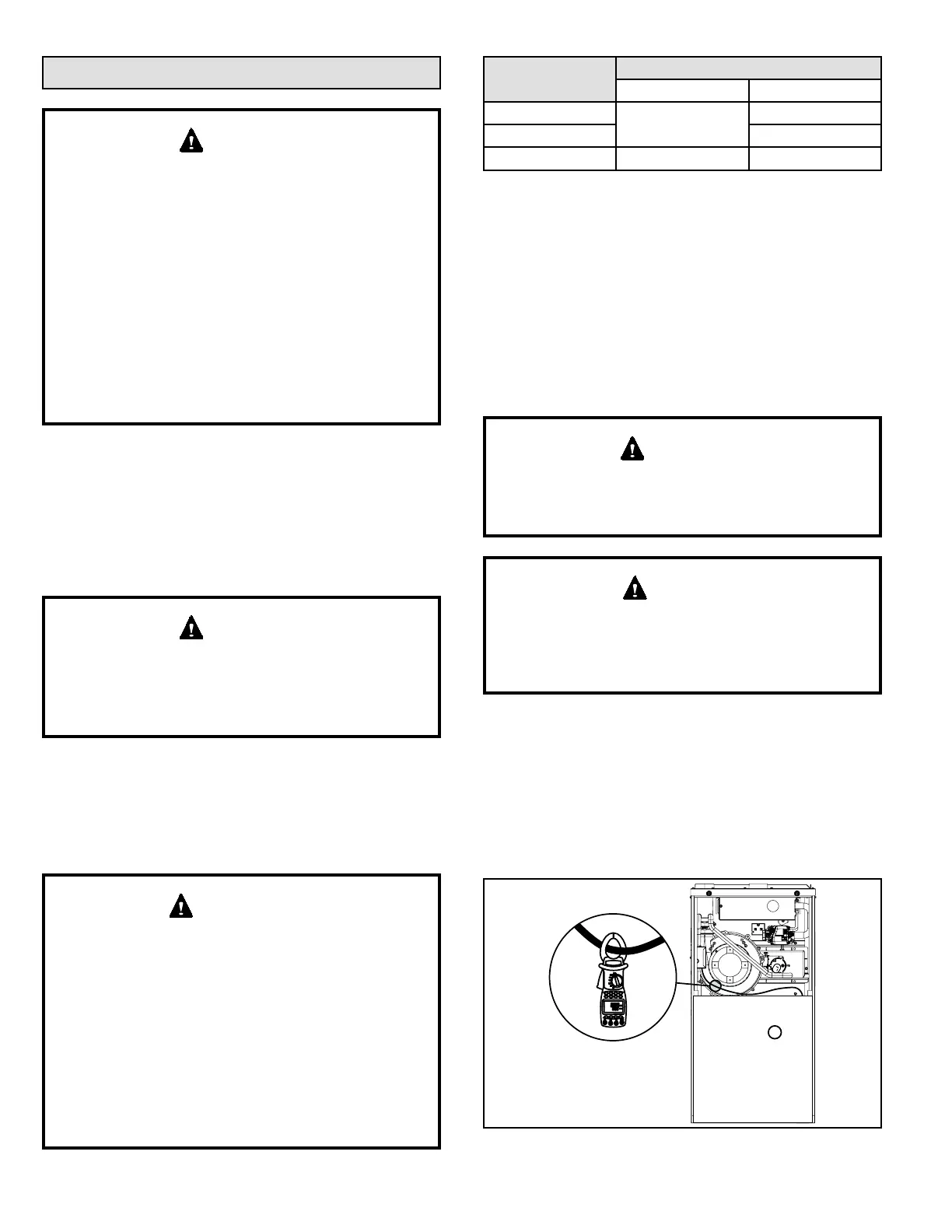

1. Check all wiring for loose connections.

2. Check for the correct voltage at the furnace (furnace

operating). Correct voltage is 120VAC + 10%

3. Check amp-draw using a true RMS meter on the

blower motor with blower access panel in place. See

Figure 56.

Unit Nameplate_____________ Actual____________

Figure 56. Check Motor Amp Draw

kVAr

kWh

COMM

V3

V1

V2

P

OFF

MR

EX

1

W

3

2

True RMS Meter

Loading...

Loading...