4

VM 623.0004 GB/07.00 – Ident–Nr. 550 298

2.6 Safety instructions for maintenance, inspection

and installation

The operating company must ensure that all

maintenance, inspection and installation tasks are

performed by authorized and qualified specialist

personnel who have thoroughly studied the operating

instructions.

Work on the machine is only to be carried out when the

machine is at a standstill. The procedure for shutting

down the machine described in the operating

instructions must always be followed.

Pumps or aggregates handling fluids which are

detrimental to health must be decontaminated. All

safety and protective devices must immediately be

refitted and made operational on completion of the

work.

The instructions under Section 6.1, ”Preparation for

start–up”, must be observed before restarting.

2.7 Unauthorized conversion and production of

replacement parts

Conversion or modification of the machines is only

permissible after consultation with the manufacturer.

Original replacement parts and accessories approved

by the manufacturer are intrinsic to safe operation. If

other parts are used the manufacturer cannot be held

liable for the consequences.

2.8 Unacceptable modes of operation

The operational safety of the machine supplied is only

ensured when it is used in accordance with Section 1 of

the operating instructions. The limit values given on the

data sheet must not be exceeded under any

circumstances.

3 Transportation and Intermediate Stor-

age

3.1 Packaging

Attention must be paid to the figurative markings on the

packaging.

The suction and pressure side and all auxiliary connec-

tions must always be closed during transportation and

storage.

The coverings must only be removed im-

mediately before connecting the pipeline.

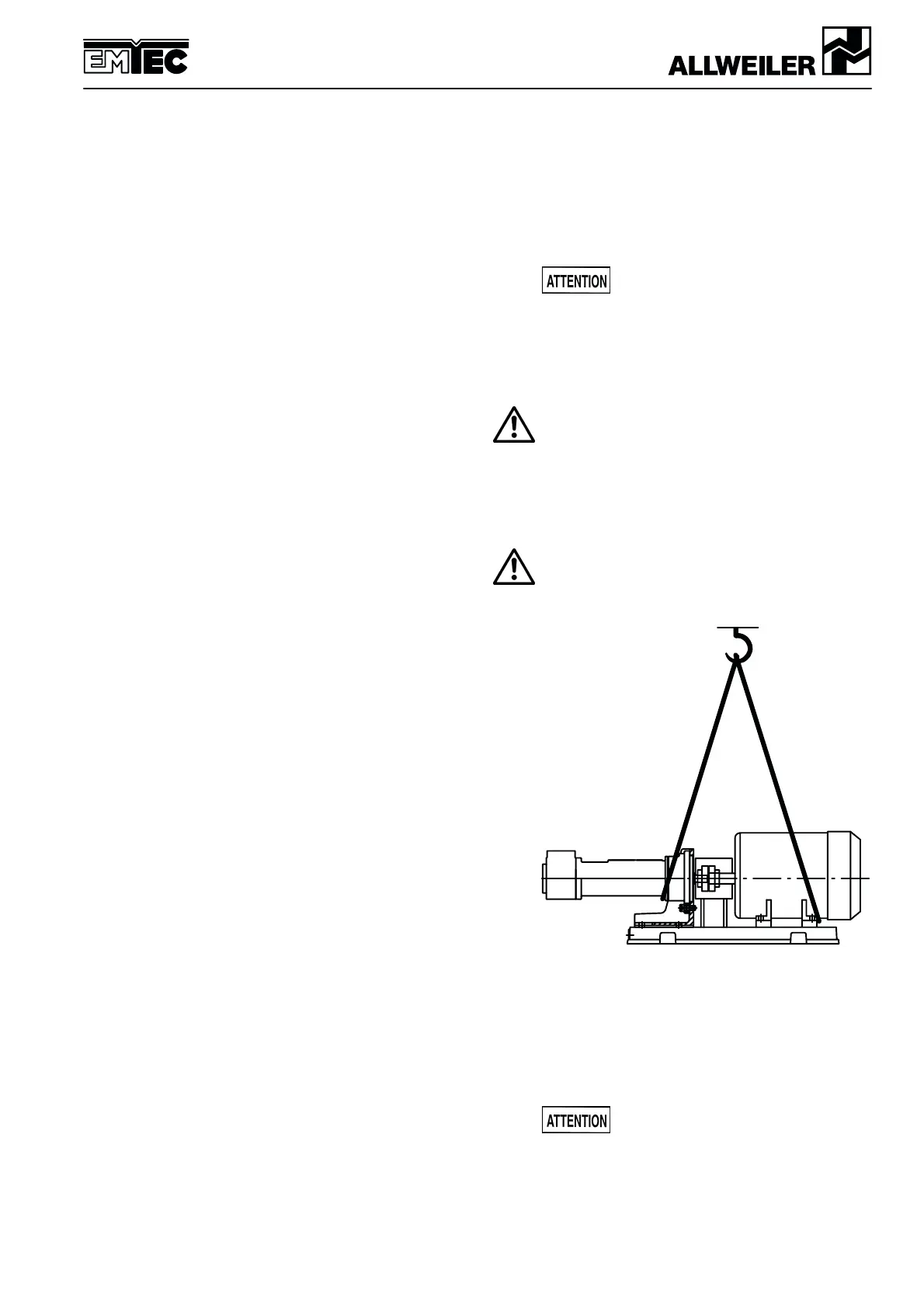

3.2 Transportation

The pump or pump aggregate is to be safely trans-

ported to the place of installation, if required by means

of lifting gear.

The regulations for lifting loads in accordance with

VBG 9a must be observed. Crane and sling equip-

ment must be adequately dimensioned. Sling

equipment must not be secured to the lifting eyes

of the motor, except as additional protection

against overturning in the event of nose–heavi-

ness.

Transportation to and at the installation site

Make sure that the unit is transported safely and in a

stable position. Overturning due to nose–heaviness

must be prevented.

Complete aggregates must be transported to the place

of installation as shown in the illustration.

Fig. 3.1: Transportation of a horizontally mounted pump

aggregate

In the case of vertically and horizontally mounted

flanged pump aggregates, it is advisable to attach the

cables to the wall/foot lantern or intermediate fitting

lantern (not shown).

Transport damage

Check the pump for damage on receipt.

Any damage detected must be notified im-

mediately.

Loading...

Loading...