8

VM 623.0004 GB/07.00 – Ident–Nr. 550 298

If a height, lateral or angle offset is detected between

the two coupling halves, the drive motor should be re–

aligned such that the coupling halves are flush with

each other (level out with flat packing shims as neces–

sary).

The gap between the two coupling halves must be the

same all round the circumference of the coupling. The

specified gap is shown in the installation diagram.

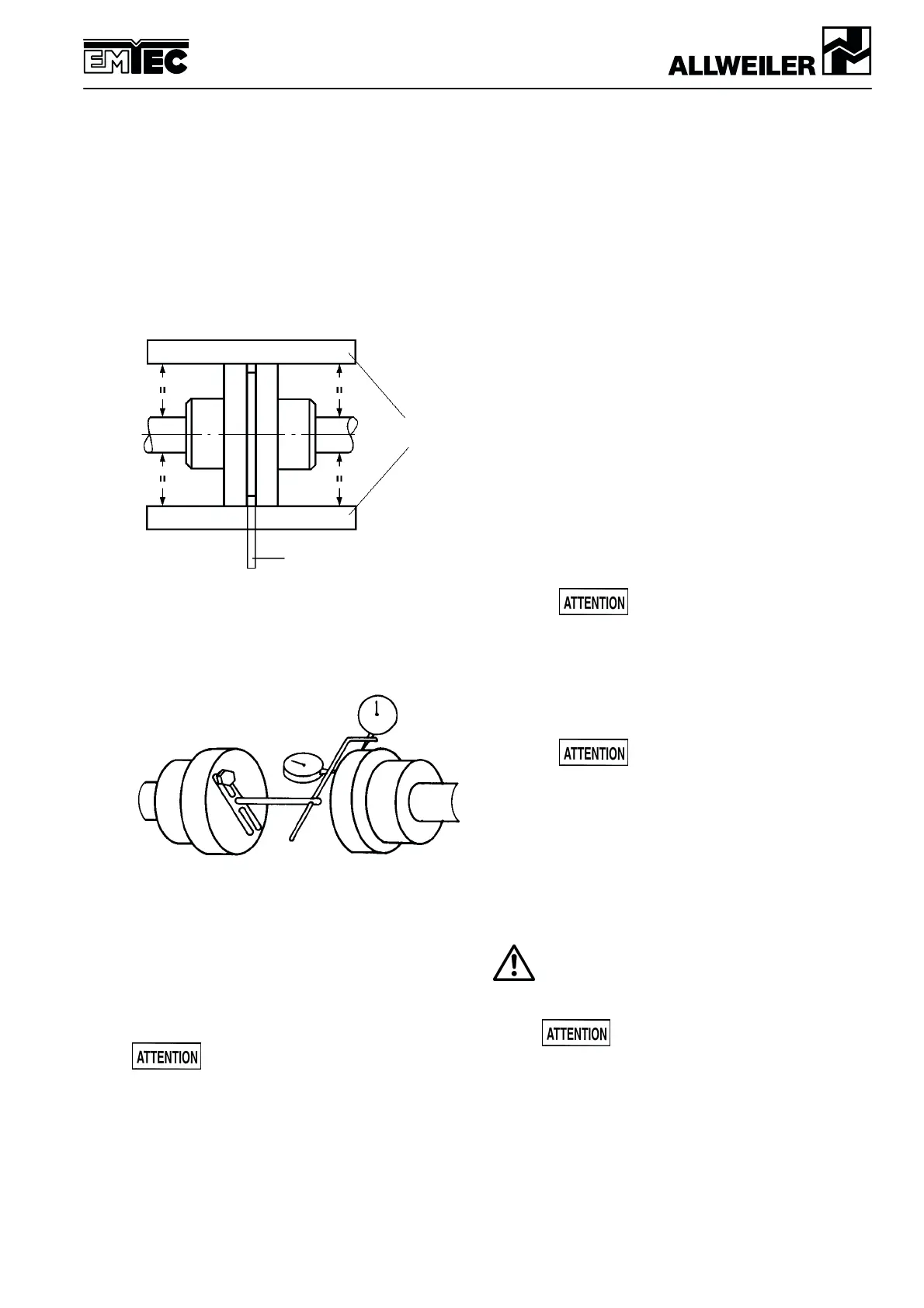

The spacing between the straight–edge laid over both

coupling halves and the respective shaft must be the

same all round the circumference.

Straight–edge

Feeler gauge

Figure 5.2: Alignment of the coupling with

straight–edge and fee–ler gauge

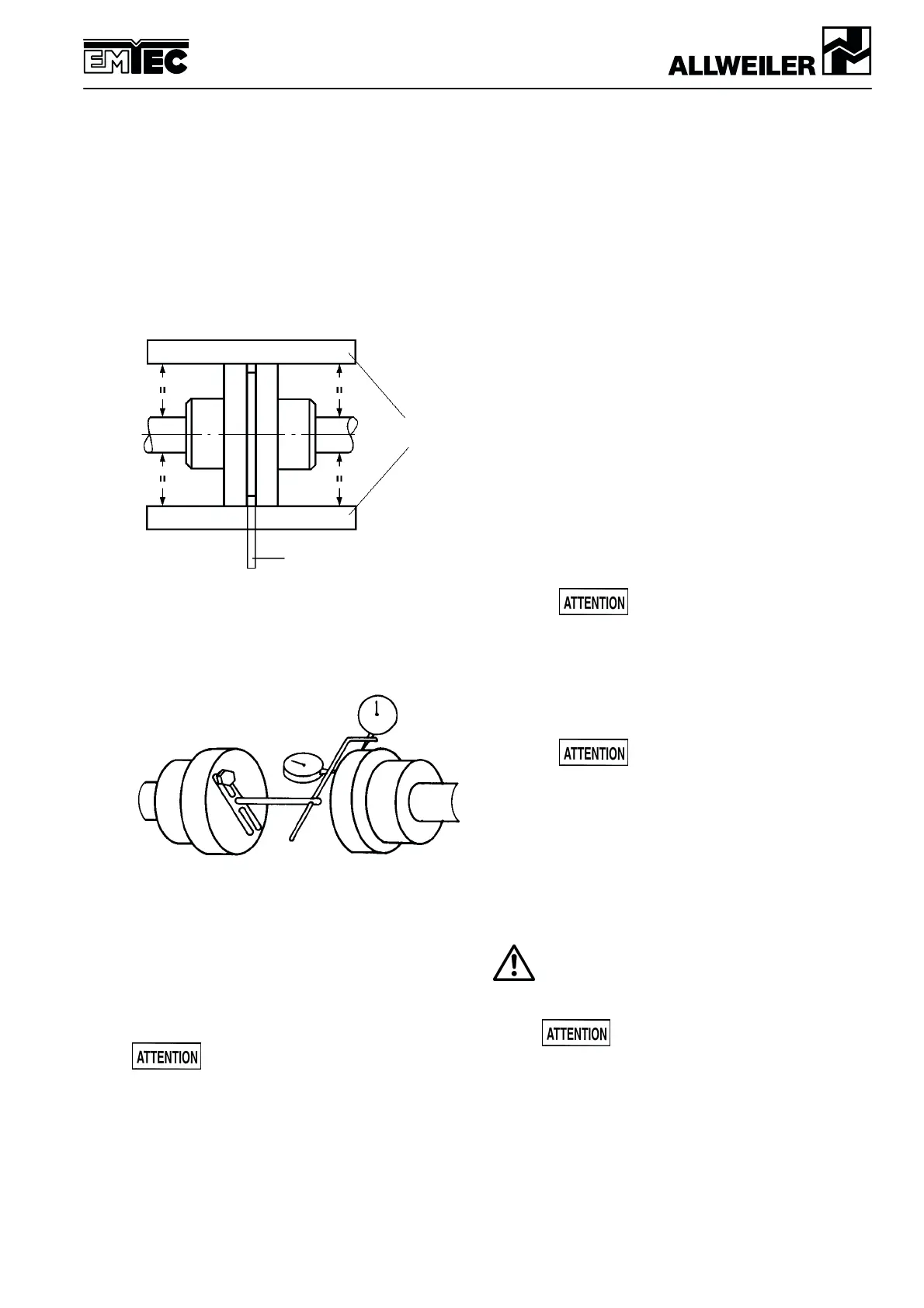

For couplings with a distance piece (removable coup-

lings) the alignment of the coupling can be checked

with dial gauges.

Figure 5.3: Alignment of the coupling with dial gauges

Note: The permissible axial and radial deviation,

measured on the front face of the coupling and the

coupling circumference respectively, may be max.

0.1 mm, but as far as possible should be kept below

0.05 mm.

Whe the fixing bolts have been aligned and tightened

the pump/drive motor unit must be able to be spun by

hand without pressure points.

Out–of–flush errors on the coupling may

lead to heavier wear of the coupling, the

anti–friction bearing and the shaft seal, and even cause

the shaft end to be torn off.

5.4.2 Coupling alignment in case of flanged aggregates

(if used)

In the case of pumps with flanged drive motor, the pump

and motor are precisely centered in the lantern. Align-

ment or re–alignment of the coupling is not requi–red.

Note: Improper handling, e.g. during transportation,

may impair the alignment between the pump and the

motor. In this case the pump and the motor must be re-

turned to the factory for checking.

5.4.3 Coupling alignment of special designed couplings

(if used)

Refer to the operating instructions of the coupling

manufacturer.

5.5 Assembly of pump and drive motor

If the aggregate is only assembled at the place of use,

the following worksteps take place:

1. Coat the pump and motor shaft ends with a fine film

of molybdenum disulfide (e.g. Molykote) and insert

keys.

2. Push on the coupling halves on the pump and motor

side with the aid of a pusher device.

Refer to Assembling Instruction VM 623.0004–1/...

If no puller is available, heating the coupling halves

to approx. 100°C (without rubber buffer) facilitates

pushing.

The possibility of shock and stress on

the pump and drive motor components

must be eliminated.

3. Tighten the grub screw on both coupling hubs.

4. When assembling the pump and motor, make sure

the specified gap between the coupling halves is

maintained.

The pump casing up from size 210 must

be supported additionally at the site

(see installation drawing).

5. In the case of horizontally mounted pump aggre-

gates fixed on a base plate or directly on the founda-

tion, the coupling must be aligned as described in

Section 5.4.

In the case of pump aggregates with flanged motor,

the coupling does not need to be re–aligned.

6. Mount the contact protection.

According to accident prevention regulations, the

pump must only be operated with a protection

against accidental contact.

5.6 Space required for maintenance and repair

The pump must be accessible from all

sides in order to be able to carry out

necessary visual inspections.

Adequate space must be provided for maintenance

and repair work, in particular for removal of the drive

motor or of the complete pump aggregate. It must also

be ensured that all pipelines can be attached and

removed without hindrance.

Loading...

Loading...