Veb- MN (Excell-MCDSe 400)#A(15-5-2007)(in).doc

15

CLEANING AND STERILIZATION

1. Clean the unit with a neutral soap solution, by taking care that no liquid goes inside, and then wipe it by a dry cloth. Clean the pedal

foot-switches in the same way, or with a cold disinfectant solution (i.e. “Amuchina”);

2. Attention: at the moment of the sale the accessories are not sterile.

The following accessories can be sterilized in autoclave (gloves cycle at 121°C for 20min / 134°C for 10min), or with cold solutions

(i.e. “Amuchina”):

- The electrodes-holder handles (MPE/E, MPE/CMS) and all the active electrodes;

- The cables and the forceps for bi-coagulation, the cables and the forceps (scissors, cannulae) for monopolar coagulation;

- The cables and the monopolar/bipolar electrodes for laparoscopy.

The reusable neutral electrodes with their cables can be sterilized only with cold solutions (i.e. “Amuchina”).

During the sterilisation, do not bend too much the connection cables, and wipe perfectly all the parts of the accessories before using them, in

order to eliminate all traces of humidity. The best thing to do is to centrifuge them.

ENVIRONMENTAL and ATMOSPHERIC CONDITIONS for USE, TRANSPORT and

STORAGE

The environmental use and preservation conditions are the following ones:

Temperature (°C): +10 ÷ +40 – Humidity: 30% ÷ 75% - Pressure (hPa): 700 ÷ 1060.

The unit must not be used at less than 30cm from the wall or other objects that can obstruct the ventilation areas, and it must be placed on a

trolley or a support (there are two screwed points under the basis for the fixing).

When the unit is not used, it must be kept in a dry place, not dusty. Be aware that no liquid is poured on it.

The environmental transport and storage conditions are the following ones:

Temperature (°C): -40 ÷ +70 - Humidity: 10% ÷ 95% - Pressure (hPa): 500 ÷ 1060.

For the shipment of the unit, we suggest to use the original packaging, or at least a new one that can guarantee the same reliability.

MAINTENANCE and DISPOSAL

The unit must be regularly checked (once per year) by qualified personnel, even better if by the Manufacturer himself. Check always the

perfect condition of the accessories, because otherwise their use can be dangerous.

Its disposal must be done according to the different National Rules, by bearing in mind that the accessories (notably the active and neutral

ones) get in contact with the patients tissues, and therefore require a special attention.

SELF-DIAGNOSIS and SELF TEST SYSTEM, CONTROL of the ERROR CODES

The unit is equipped with a self-diagnosis system, which automatically intervenes in case of functioning problems, included the delivery of

powers that are higher than the set ones. It stops the device and informs the operators through specific alarm signals (Error Codes), which

can be either acoustic (loud and intermittent sound) or also visual (see the Tables Codes for Wrong Use or Activation Circuit Fault – Codes

for System Fault).

When the device is turned on, this control system carries out a complete self-test cycle over the hardware and the software (all the Led and

displays light up, and the loudspeaker is activated). If everything works properly, this phase ends by a short acoustic signal.

If the system detects any problem, the faults are indicated as described above, and the operator must either try to eliminate all the possible

causes, or switch the equipment off and ask for a technical assistance.

When the device is running, this control system checks the functioning of the unit, included the output powers (2000 times per second), by

repeating the complete test on the functioning every 20 minutes (in an activation interval).

Even in this case, the problems are indicated as described above (“When the device is turned on”).

Control of the Error Codes

The unit stores the last 32 Error Codes that have been detected, in order to help the operators in finding a solution for the problems/faults.

The procedure to follow for this control is detailed into the Service Manual.

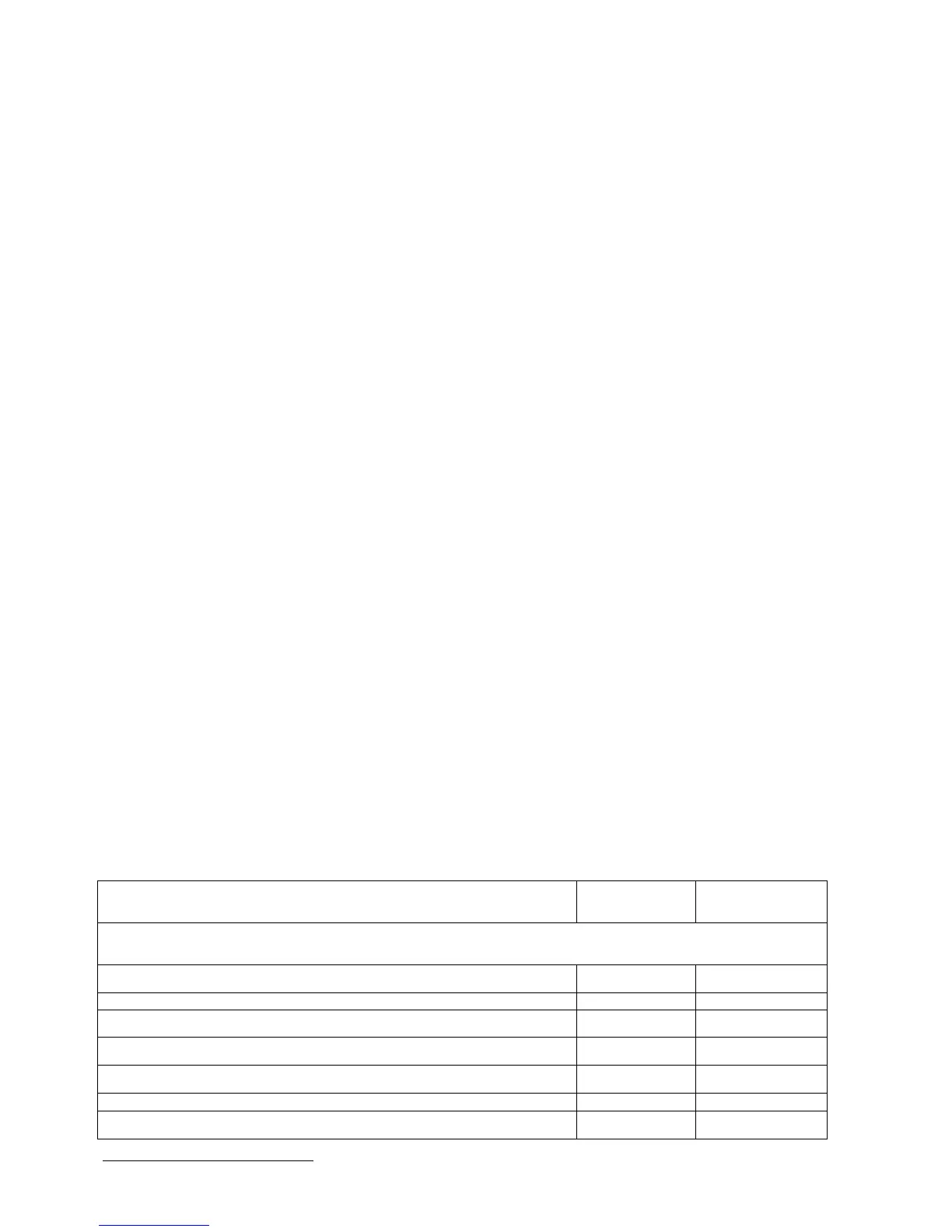

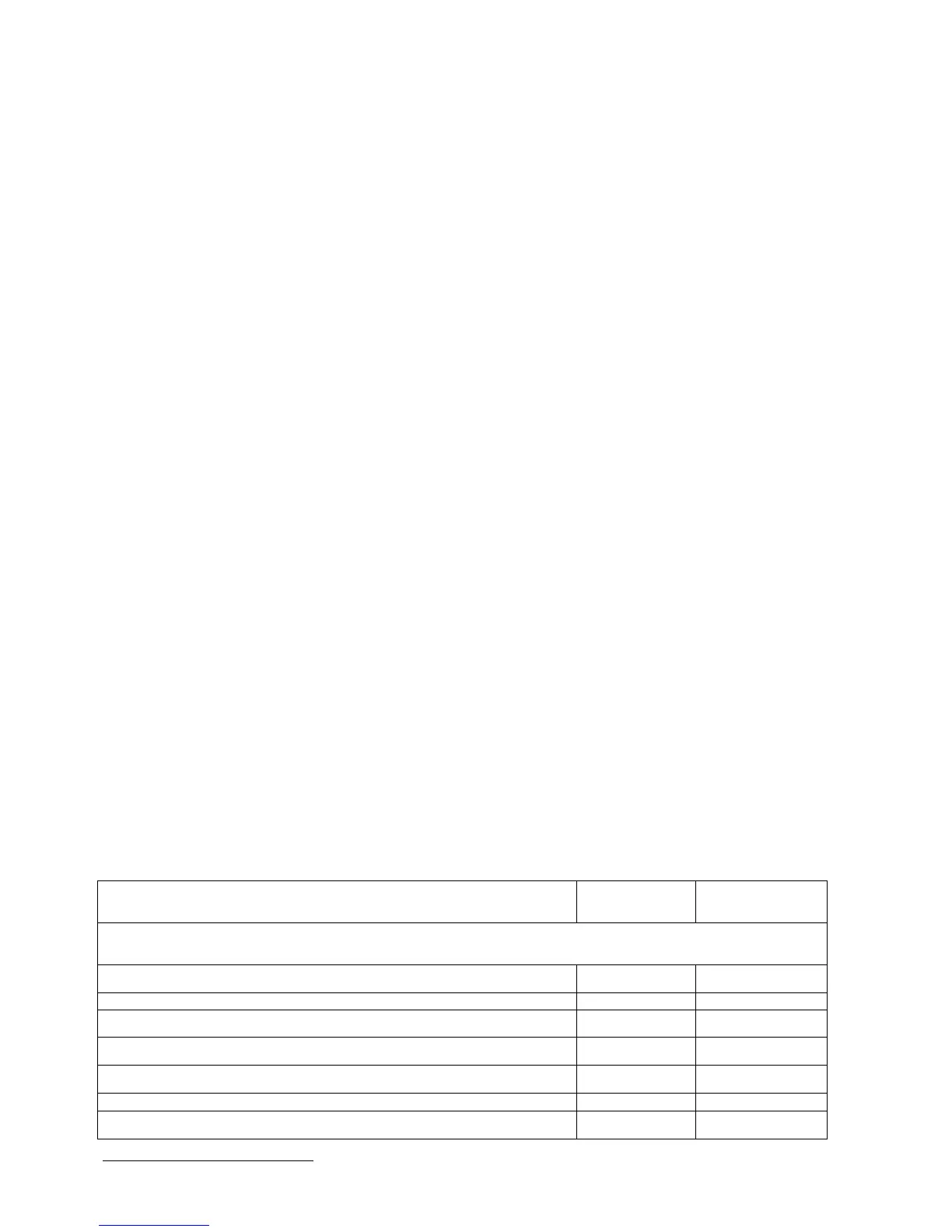

ERROR CODES TABLE

Error description Error code

Stored code in

E

2

PROM (select “

0d

”

in CAL mode)

1

Codes for Wrong Use or Activation Circuits Fault

For all the “U” problems, the operators can act by eliminating the cause of the intervention of the self-diagnosis system.

In all the other cases, ask for the technical assistance, after having checked the signal by switching off and on the unit

U) Problem into the neutral electrode (broken cable, non connected cable to the unit or

to the neutral electrode, neutral electrode “split” type not attached to the tissues

no nP

-

Failure into the neutral electrode control circuit (internal fault)

Err nPC 81

Failure into the control circuit of the contact between the neutral electrode/the patient

(internal fault)

Err 53 35

Failure of an activation hand-switch at the switching on;

U) Activation hand-switch pressed at the switching on

Err Hnd 82

Failure of a pedal foot-switch at the switching on;

U) Pedal foot-switch pressed at the switching on

Err PEd 83

U) Contemporary activation not allowed of the two activation devices

USr Act

-

Failure of a key on the control panel;

U) Key on the control panel pressed at the switching on

Err 14 0E

1

Inside the E

2

PROM hexadecimal value corresponding to one of error codes reported on “Error code” column in the above table are stored.

Loading...

Loading...