Excell MCDSe series

Rel. 1

alsa apparecchi medicali srl 5

from the visualization of the calibration parameter to the visualization of the power setting (by remaining in

the calibration mode); in order to proceed to the next calibration, it is necessary to press the CAL button

again and go back to the mode of the monopolar section with the blinking displays. The following Table

shows the whole list of the selectable tests:

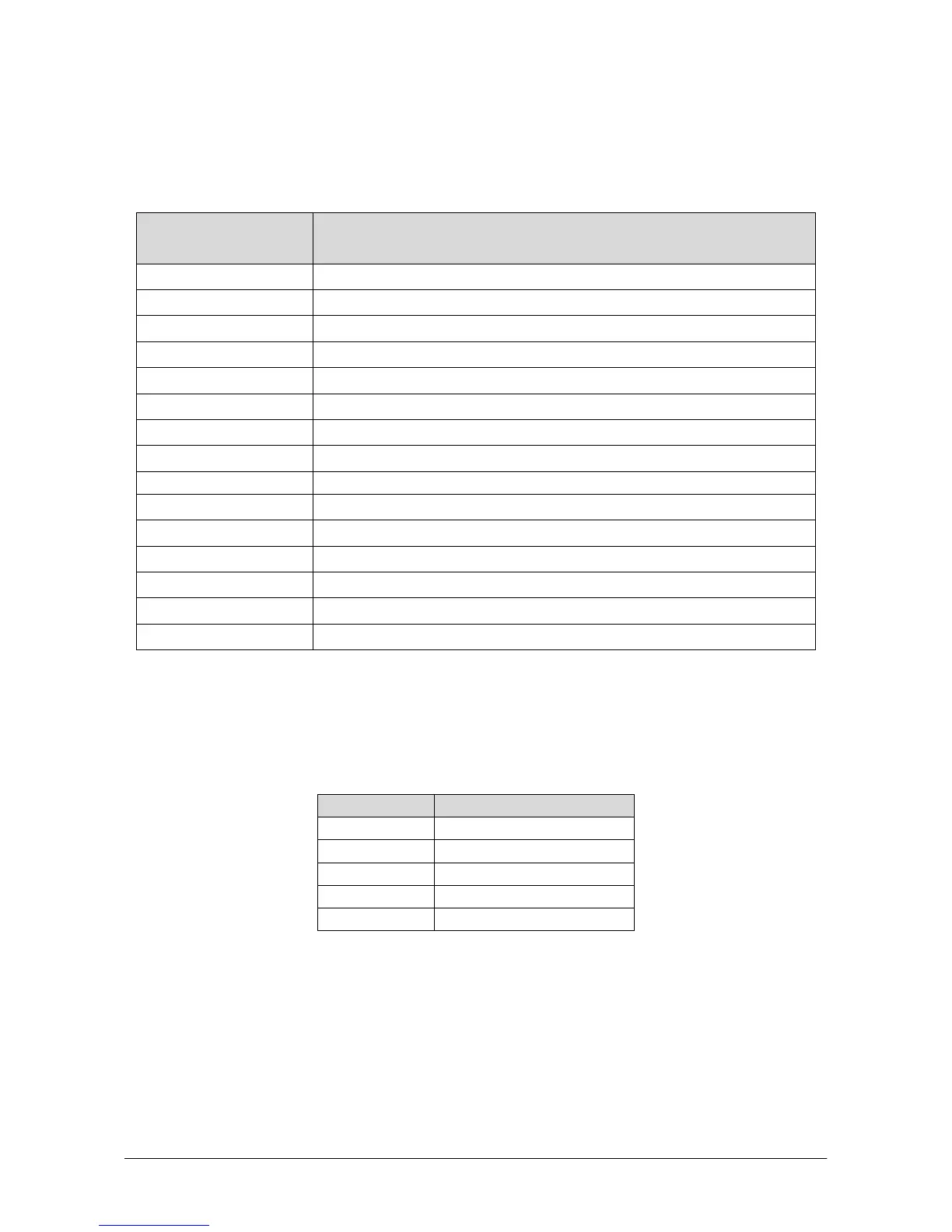

Monopolar Cut Display

Test n°

Description

00

Continuous supply of the power stage

01

Internal parameters of the R.F. section

02

Functioning of the R.F. section without feed-back

03

Peak voltage R.F. (Voutpk)

04

Drain current into the mosfets of the R.F. section

05

R.F. leakage current with control made by the software

06

R.F. leakage current without control

07

Start/Stop impedance adjustment for the automatic bipolar mode

08

Not Used

09

Reading of the data that come from the analogical inputs of the micro Slave

0b

Visualization of the current software release

0C

Loading of the default values

0d

Reading of the errors memorization

0E

Cancellation of the errors list into the E

PROM

CALIBRATION OF THE POWER SUPPLY SECTION – SETTING OF THE LOW VOLTAGES

Before proceeding with the calibration of the section that controls the supply of the power R.F. generator

stage, it is necessary to verify the continuous low voltages. To do that, connect the positive terminal of a

multimeter to the points indicated in the following Table:

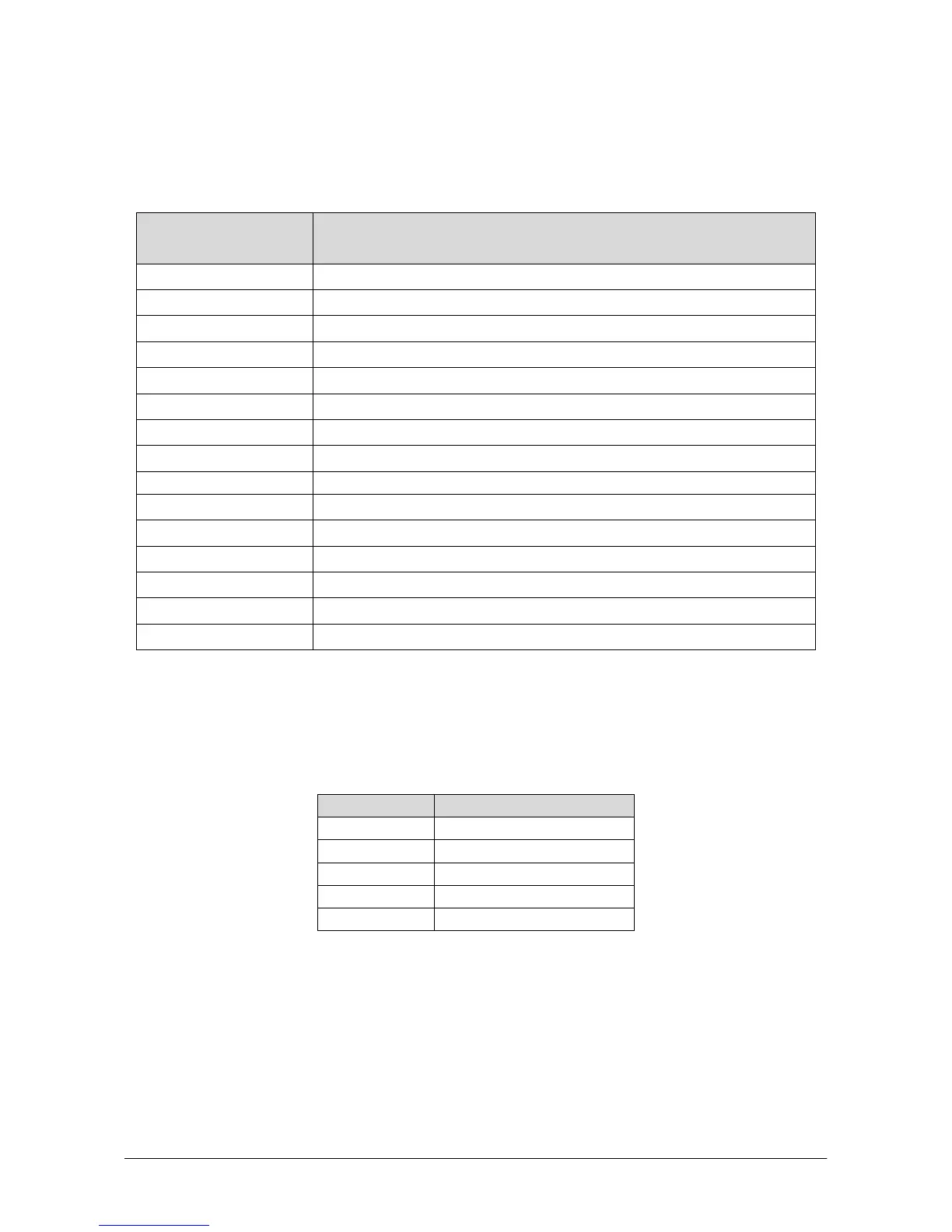

Test Point Voltage (VDC)

L6 +5.08

L7 -15V

L8 +15V

U6 (pin 3) +24V

U13 (pin 3) +5V

Set the R31 pot placed on the Power Supply board (Alsa code: 801471) in order to set exactly the +5V

continuous voltage for the microcontroller section.

CALIBRATION OF THE MASTER MICROCONTROLLER BOARD REFERENCE VOLTAGE

If present, remove the J11 jumper.

Connect a multimeter between the test point J10 and GND; set the R102 pot placed on the Master

Microcontroller board (Alsa code: 801469) in order to obtain a voltage of 5.00V (± 0.01V).

Once the calibration has been performed, close the J11 jumper.

Loading...

Loading...