Maintenance

Maintenance p lan

P51--0001EN/02

3/6

01--2011

© ALSTOM 2010. All rights reserved. Information contained in this document is indicative only. No representation or warranty is given or should be

relied on that it is complete or correct or will apply to any particular project. This will depend on the technical and commercial circumstances. It is

provided without liability and is subject to change without notice. Reproduction, use or disclosure to third parties, without express written authority, is

strictly prohibited.

GRID

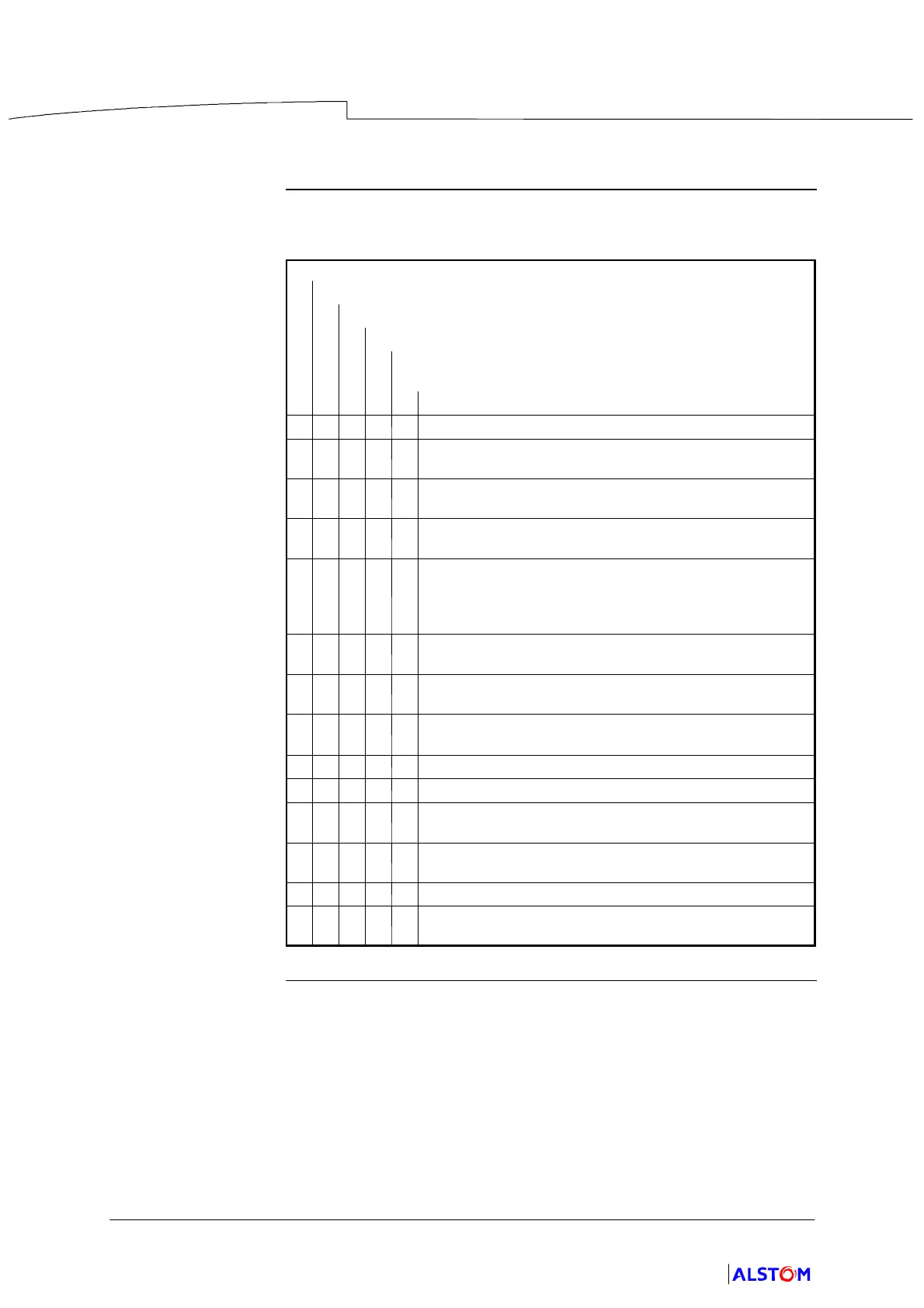

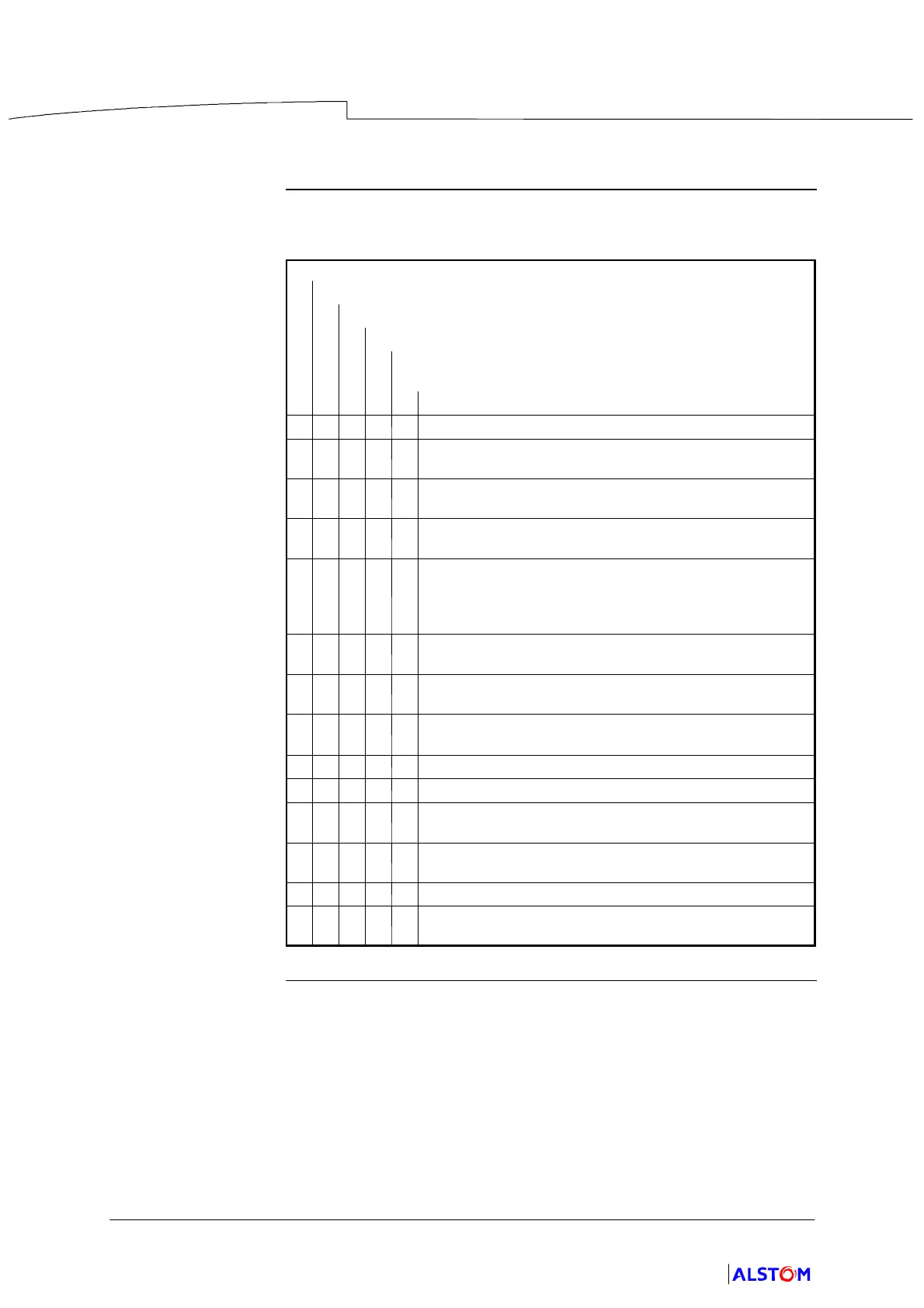

Maintenance operations

Guide to

The following table is a guide to the operations to be carried out at each

maintenance step :

MAINTENANCE VISIT (1 or 2 times per year)

INSPECTION (every 5 years)

REVISION (SERVICE LIFE : 20 years)

REVISION (MECANICAL ACTUATORS : 3 000 cycles)

REVISION (ELECTRICAL WEAR : see ’Limit of electrical

wear”)

J J J J J

Read the actuator counters.

J J J

General inspection : visual aspect (corrosion, paint,

trace of heat).

J J J J J

Check the permanent heating functions. Check the

condition of the air vents

J J J

If the circuit breaker is equipped with a SF

6

densimeter

with a dial, check that the needle is in the green zone.

J

We recommend at least 2 CO cycles CO per year for

circuit breakers that are infrequently used, to check

proper functioning of the circuit breaker and the

associated command--control circuits.

J J

Check the SF

6

contact densimeter thresholds. Then

adjust the pressure to nominal pressure.

J J J

Check the tightening of the fasteners for components

not under pressure (frame, plate, cabinet).

∗ J J J

Check the tightening of the low voltage terminals (∗ 6

months after commissioning).

J J J

Check the relays are functioning.

J

Change the door, side panels and ceiling seals.

J J J J

Measure the pole and auxiliary contact duration of

opertion.

J J J J

Carry out operations at recommended cycles and

nominal voltage.

J J

Replace (or recondition) the breaking chambers.

J

Check to see that the opening damper piston of the

control is not leaking oil.

Loading...

Loading...