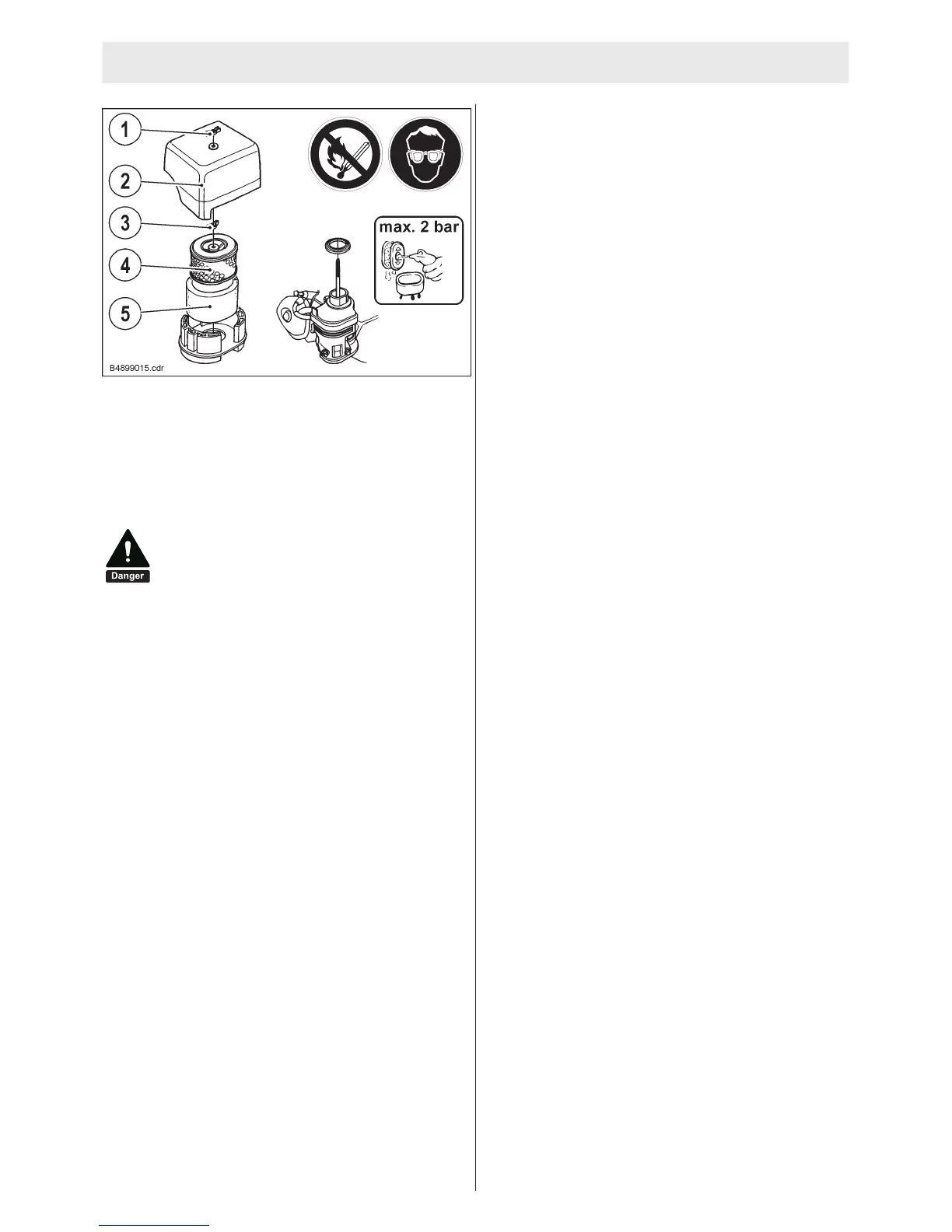

• Re move the wing nut (1) from the air cleaner cover (2), and re -

move the cover.

• Re move the wing nut from the air fil ter (3), and re move the fil -

ter.

• Re move the foamfilter (5) from the pa per fil ter (4).

• In spect both air fil ter el e ments, and re place themif they are

dam aged. Clean the air fil ter el e ments if they are to be re used:

• Pa per air fil ter el e ment:

- Blow dry com pressed air (max. 2 bar / 29.007 psi) through

the fil ter car tridge (4) from the in side out.

• Foam air fil ter el e ment:

- Clean in warm soapy wa ter, rinse, and al low to dry thor -

oughly. Or clean in non-flam ma ble sol vent and al low to dry.

- Dip the fil ter el e ment (5) in clean en gine oil, then squeeze

out all ex cess oil. The en gine will smoke when started if

toomuch oil is left in the foam.

• Wipe dirt from the in side of the air cleaner case and cover us -

ing a moist rag. Be care ful to pre vent dirt fromentering the air

duct that leads to the car bu re tor.

• Place the foam air fil ter el e ment (5) over the pa per el e ment

(4).

• Re in stall the as sem bled air fil ter. Be sure the gas ket is in

place be neath the air fil ter.

74020000-2 HbmG gnu thci dreV nna mmA 7102/90

6. Main ten an ce en gi ne

55

Risk of in jury.

When work ing with com pressed air, for eign bod -

ies can go into the eyes.

• Wear safety spec ta cles

• Never point the jet of com pressed air at a per son

or one self.

Loading...

Loading...