Do you have a question about the AMP Research BedStep 75313-01A and is the answer not in the manual?

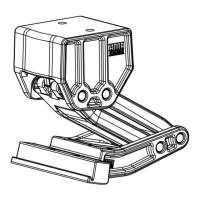

Assemble bracket components as shown without initial tightening.

Prepare the linkage by securing it firmly in a vice.

Apply specified torque values to bolts during assembly stages.

Remove one nut completely and loosen others for bracket positioning.

Set bracket assembly over key hole and slide flush to frame rail.

Snug mounting bolts, ensuring bracket is flush and square, but do not torque.

Confirm proper bumper alignment before proceeding with final torquing.

Torque main mounting bolts to specified values after alignment.

Insert and torque PT screws into corresponding holes on the step pad.

Foot-operated deployment and retraction of the BedStep.

Information on the maximum weight capacity for the BedStep.

Guidance on washing and cleaning the step pad and linkage arms.

Crucial safety reminder to keep BedStep stowed when the vehicle is in motion.

Covers defects in material and workmanship for three years.

Instructions on how to initiate a warranty claim and required documentation.

Specifies conditions and damages not covered by the warranty.

The AMP Research BedStep is a foot-operated, retractable step designed to assist users in accessing the cargo bed of their Ford Super Duty F250/F350/F450 trucks (model years 2017-2021). This device is engineered for convenience and ease of use, providing a sturdy platform that deploys and retracts with a simple foot motion. The BedStep is an American-designed, engineered, and manufactured product, built to enhance the functionality of pickup trucks.

The primary function of the AMP Research BedStep is to provide a deployable step for easier access to the truck's cargo bed. When not in use, the step retracts neatly under the bumper, maintaining the vehicle's aesthetic and ground clearance. This mechanism is particularly useful for individuals who frequently load or unload items from their truck bed, or for those who find it challenging to step up into the bed without assistance. The step is designed to be robust, offering a secure and stable platform for users.

The BedStep is characterized by its intuitive, foot-operated deployment and retraction. To deploy the step, the user simply presses down on the forward outside corner of the step pad with their foot. This action causes the step to swing out and down into a usable position. To retract the step, a gentle kick to the underside of the step pad is all that's required, causing it to fold back up and stow away. This hands-free operation is a significant convenience, especially when the user's hands are full.

The installation process for the BedStep involves several steps, ensuring a secure and proper fit. It begins with assembling the bracket components, specifically Bracket A and Bracket B, as shown in the provided diagrams. These brackets are then positioned and secured to the truck's frame. The manual emphasizes the importance of not fully tightening bolts until all components are in place and aligned, allowing for adjustments to ensure the bracket remains flush and square with the frame rail. Specific torque values are provided for different bolts to ensure structural integrity and safety. For instance, the bolts connecting the linkage to the main bracket are torqued to 16 ft-lbs / 22 Nm, while the bolts securing the main bracket to the vehicle's frame are torqued to 33 ft-lbs / 44 Nm. The installation also involves securing the linkage in a vice during certain steps to facilitate proper assembly.

The device is designed to integrate seamlessly with the truck's existing structure. During installation, it's crucial to verify bumper alignment before torquing the main attachment bolts to ensure that the step operates correctly and does not interfere with other vehicle components. The use of tools such as a 3/16" T-handle hex key, 13mm box wrench, 6" wobble extension, 3" extension, and various sockets (13mm, 15mm, 21mm deep well) is specified for the installation process. The manual also highlights the importance of using a wobble extension for certain bolts to aid in accessibility.

Once the main brackets are in place, the step pad itself is attached using PT screws. These screws are torqued to a lower value of 6 ft-lbs / 8 N.m, with a specific warning against overtightening, which could damage the step pad. The final steps of installation involve ensuring all nuts are tightened to their specified torque values and that the bracket assembly is flush and square.

The BedStep is designed for durability and safety. It is crucial to always use appropriate handholds when stepping up to or down from the truck's cargo bed, even with the assistance of the BedStep. This ensures maximum stability and reduces the risk of falls. The step is intended to be a supplementary aid for accessing the bed, not a replacement for safe climbing practices.

Maintaining the AMP Research BedStep is straightforward, focusing on keeping the step pad surface and linkage arms clean to ensure smooth operation and longevity. The recommended cleaning method involves using mild soap and water with a soft brush or sponge. This helps to dislodge any accumulated mud, dirt, or road grime that could potentially impede the step's mechanism or reduce traction on the step pad. After cleaning with soap, it is important to rinse the components with fresh water to remove any soap residue.

A key maintenance instruction is to avoid applying waxes, lubricants, or protectants like Armor All® to the step surface. Such products can make the step pad slippery, compromising safety and increasing the risk of falls, especially in wet conditions. The step pad is designed to provide a secure grip, and applying these substances would counteract that design feature.

For optimal performance and safety, the BedStep should always be stowed in the retracted position when driving. This prevents potential damage to the step from road debris or obstacles, and ensures it does not interfere with vehicle dynamics or other components while the truck is in motion. Stowing the step also protects its mechanical components from unnecessary exposure to the elements and wear and tear.

The product comes with a three-year limited warranty, covering defects in material and workmanship under normal use and proper maintenance. In case of a warranty claim, users are instructed to contact AMP Research customer service for instructions and to retain proof of purchase. This warranty underscores the manufacturer's confidence in the product's quality and durability, provided it is installed and maintained according to the guidelines. Professional installation is recommended to ensure proper setup and to maximize the benefits of the warranty.

| Product Type | BedStep |

|---|---|

| Part Number | 75313-01A |

| Weight Capacity | 300 lbs |

| Installation | Bolt-on |

| Finish | Black powder coat |

| Category | Automobile Accessories |

Loading...

Loading...