OptiMeOptiMe

2021/01 Rev. 0.4

6 / 38

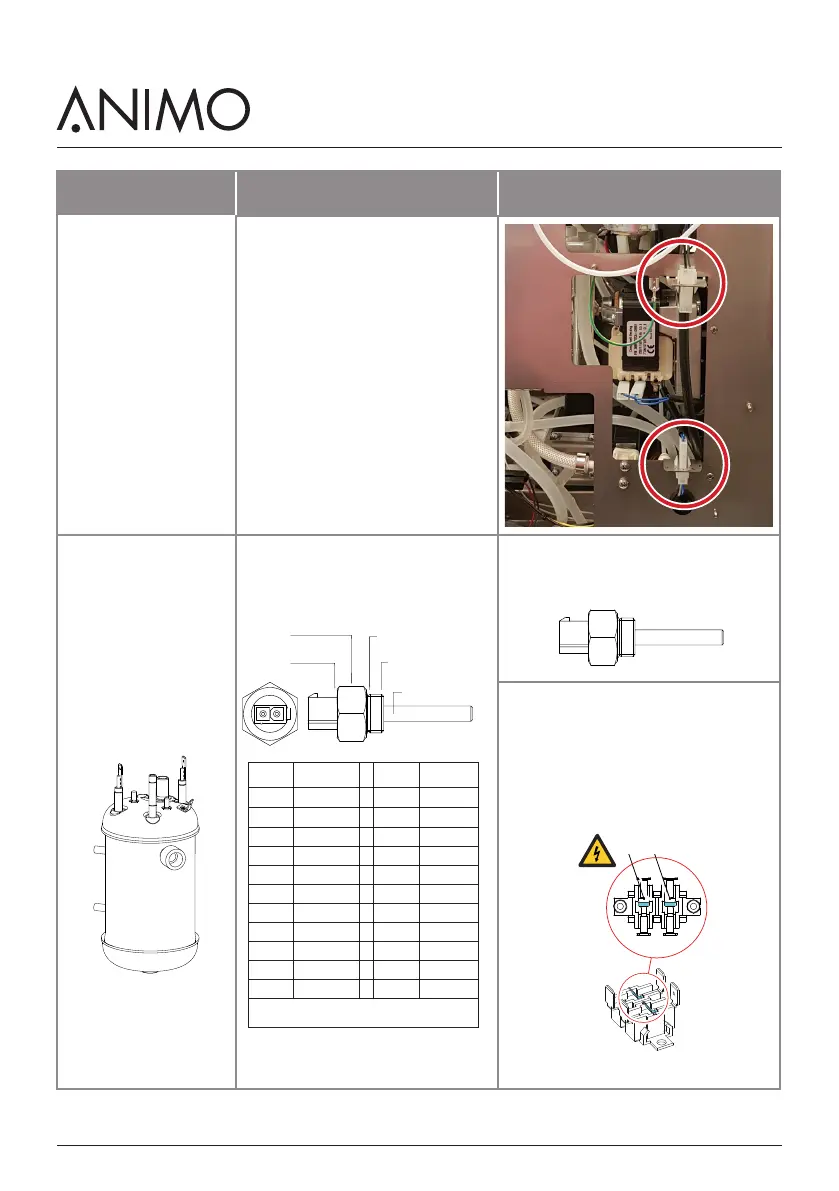

Display Possible cause Solution

E5

BREWER ERROR

The problem can be caused by bad

contact sockets from the 2 and 4

pole Molex connectors. Check if

all the socket (male/female) make

contact with each other.

The connectors are to be found

behind the left panel.

The 2 pole Molex is responsible for

the motor signal 230Vac.

The 4 pole Molex is responsible

for the position switch signals (low

voltage).

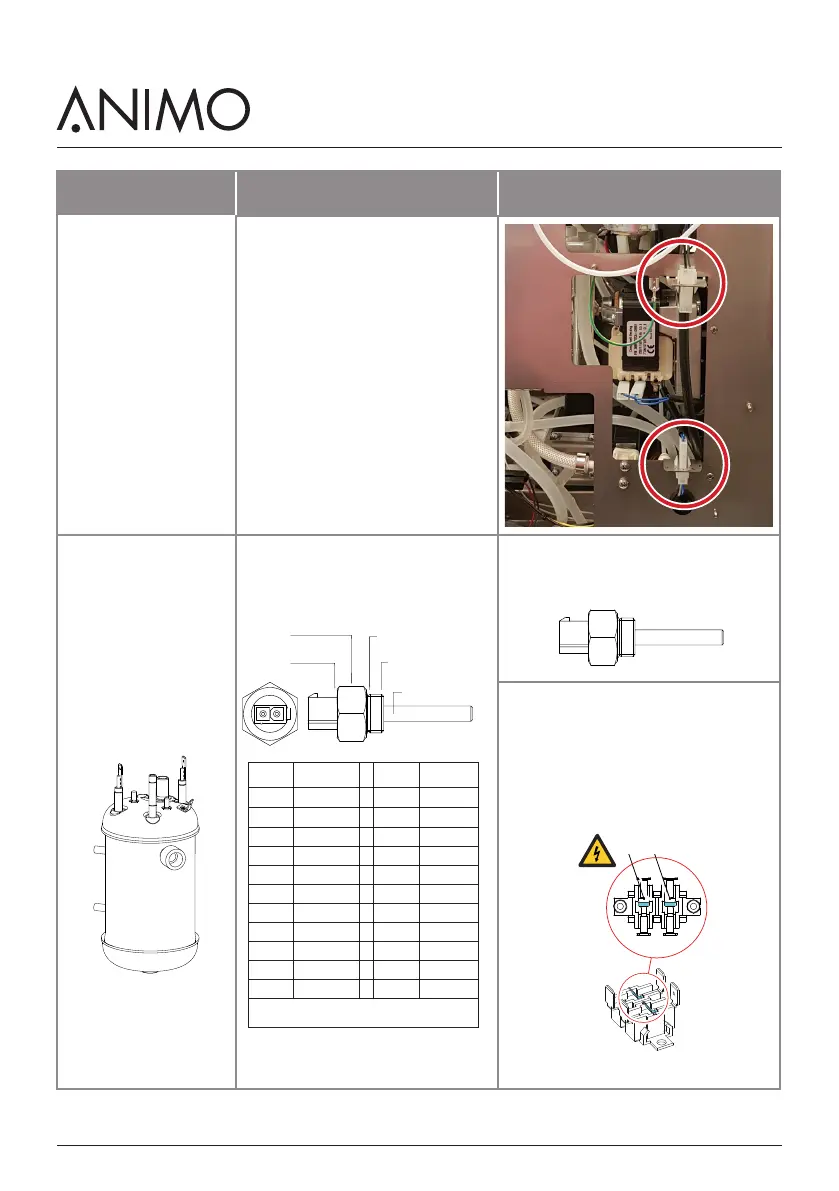

E6

TEMPERATURE HOT

WATER BOILER TO

HIGH

Temperature sensor measures a

temperature over 105 °C.

The control has disabled the heater

output.

AISI 316L / 1.4404

O-ring 10,82 x 1,78mm

M12 x 1

HEX17

ww-yy

T (°C) R (Ohm) T (°C) R (Ohm)

0 334.000 70 16.874

10 201.660 75 14.198

20 125.470 80 11.998

25 100.000 85 10.181

30 80.223 90 8.674

40 52.589 95 7.419

45 42.951 100 6.369

50 35.272 120 3.581

55 29.119 140 2.117

60 24.161 160 1.307

65 20.144

NTC resistance table

Check the temperature sensor operation

in the service menu 2.07 Hardware test

/ inputs / temperature.

AISI 316L / 1.4404

O-ring 10,82 x 1,78mm

M12 x 1

HEX17

ww-yy

Boiler overheated, let the boiler cool

down.

Check whether the boil-dry protection

was activated. Reset if necessary.

Attention; the metal reset levers are LIVE!

145°C +/- 7,5K

10A / 230Vac

Reset

Loading...

Loading...