CAUTION: Before pressurizing your rst stage, check that

your MP test gauge has an overpressure relief or bleed valve.

If it does not, you must attach a properly adjusted second

stage to the rst stage to provide a safety pressure relief if

the MP exceeds 145 psi (10 bar). Failure to relieve increasing

MP may result in damage to the test gauge or the MP hose.

WARNING: If the pressure gauge rapidly exceeds 145 psi

(10 bar), there is a HP leak. Quickly close the cylinder valve

and purge the second stage or reopen the bleed valve of the

test gauge and close the cylinder valve. Failure to do so may

cause a rupture to the MP hose and/or MP gauge, which in

turn can lead to personal injury. Refer to Table 1: Trouble-

shooting Guide on p. 14 for the causes of high or unstable MP.

WARNING: Be certain not to install a MP hose into the HP

port via an adapter. Doing so may cause the hose to rupture

when pressurized, and could result in serious personal injury.

NOTE: The following steps must be performed while the rst stage

is still pressurized.

WARNING: Compressed air can be highly explosive and

is dangerous if misused. Ensure cylinder valve is opened

slowly. Use eye and ear Personal Protective Equipment when

performing any tests using compressed air.

12

3

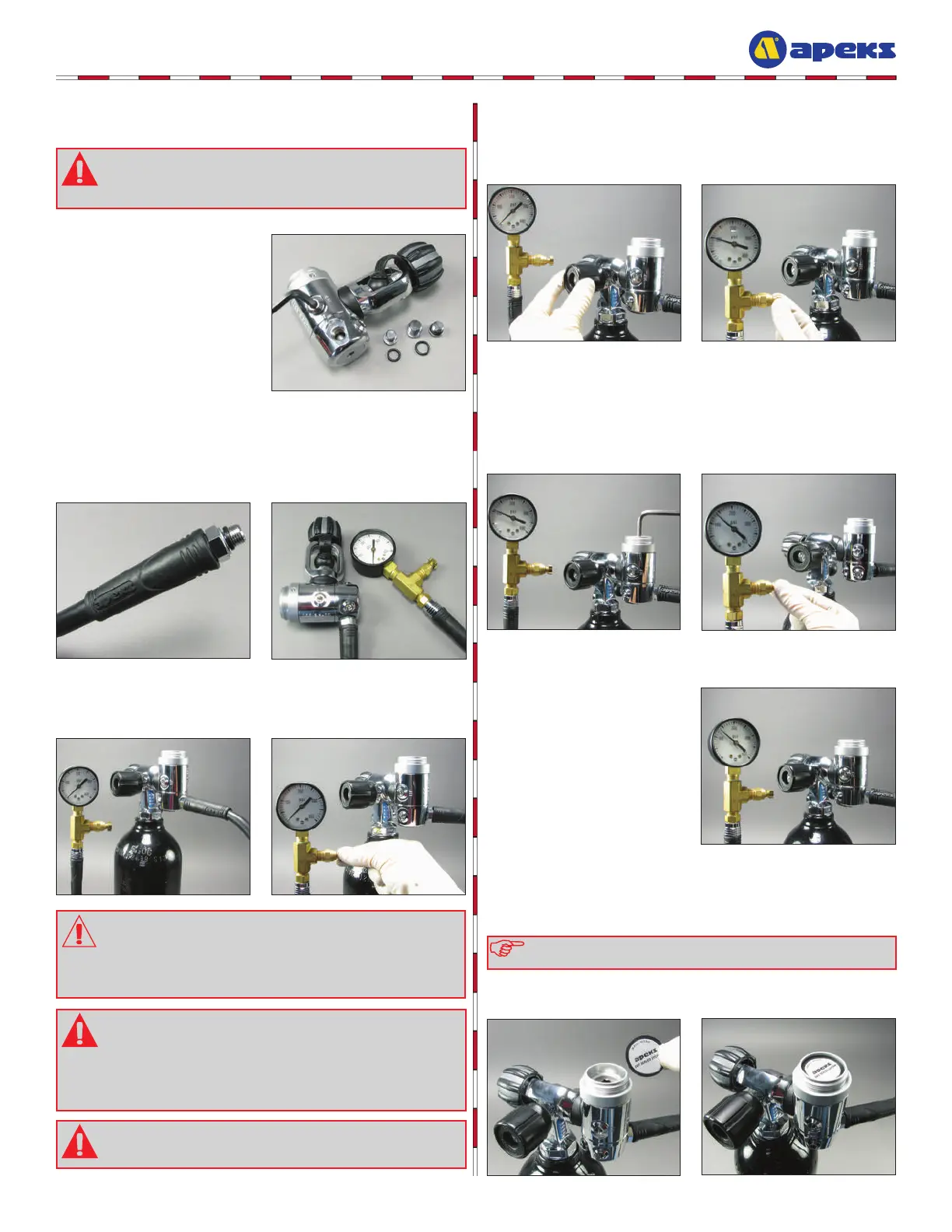

Attach the rst stage to a calibrated test bench or a cylinder lled

to 3000 psi (206 bar). Open the bleed valve on the MP gauge.

4

With the bleed valve open, slowly open the cylinder valve ¼

turn. While watching the gauge, slowly close the bleed valve. If

the MP exceeds 145 psi (10 bar) quickly open the bleed valve and

close the cylinder. If the MP is stable and does not continue to rise,

open the cylinder valve all the way.

5

Adjust the MP using a 6mm hex key. To increase the MP, turn

the adjustment screw in ⅛ turn increments clockwise. Using the

bleed valve on the gauge, cycle the rst stage several times after

each adjustment. To decrease the MP, turn the adjustment screw

counter-clockwise. Set the MP to 130-145 psi (9-10 bar).

6

Let the first stage stand

pressurized for several

minutes. Check that the MP

remains stable. If the MP rises

more than 5 psi (0.3 bar), it

indicates a leak. If the MP is

stable, close the valve, purge

the line, and pressurize once

again to perform the nal check

and assembly.

FIRST STAGE FINAL ASSEMBLY

1

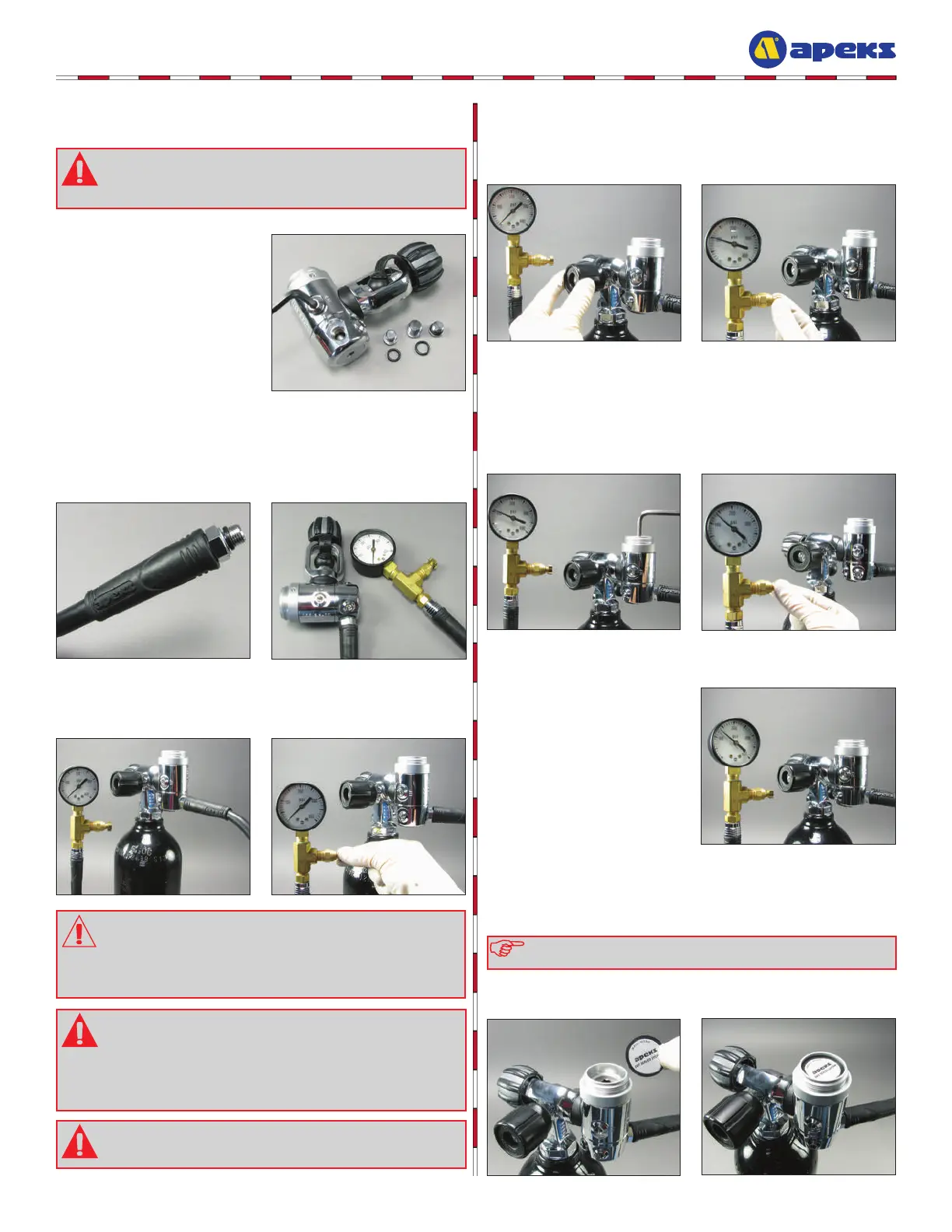

With the rst stage still pressurized, insert the hydrostatic transmitter

(23) into the dry chamber and through the adjustment screw (22).

2

Replace the o-ring on the male end of the MP hose. Thread the

hose clockwise by hand into one of the MP ports on the rst

stage. Install the MP test gauge (pn 111610) on the female end of

the hose.

ADJUSTING THE FIRST STAGE

1

Install o-rings (10,13,20) onto

all port plugs (9,18,19). Using

a 5mm hex key, install the port

plugs clockwise into the body and

tighten until snug. Leave 1 MP

port open.

Loading...

Loading...