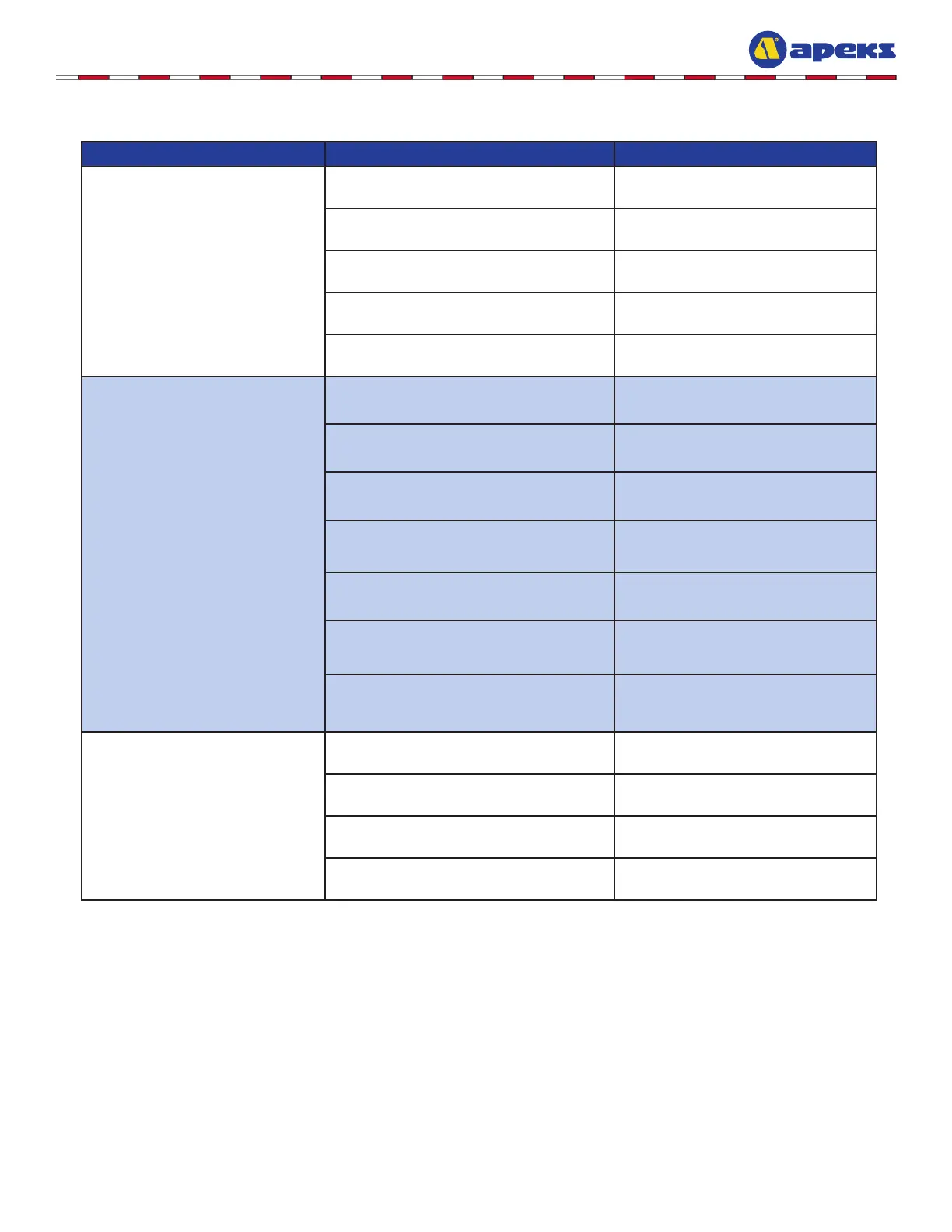

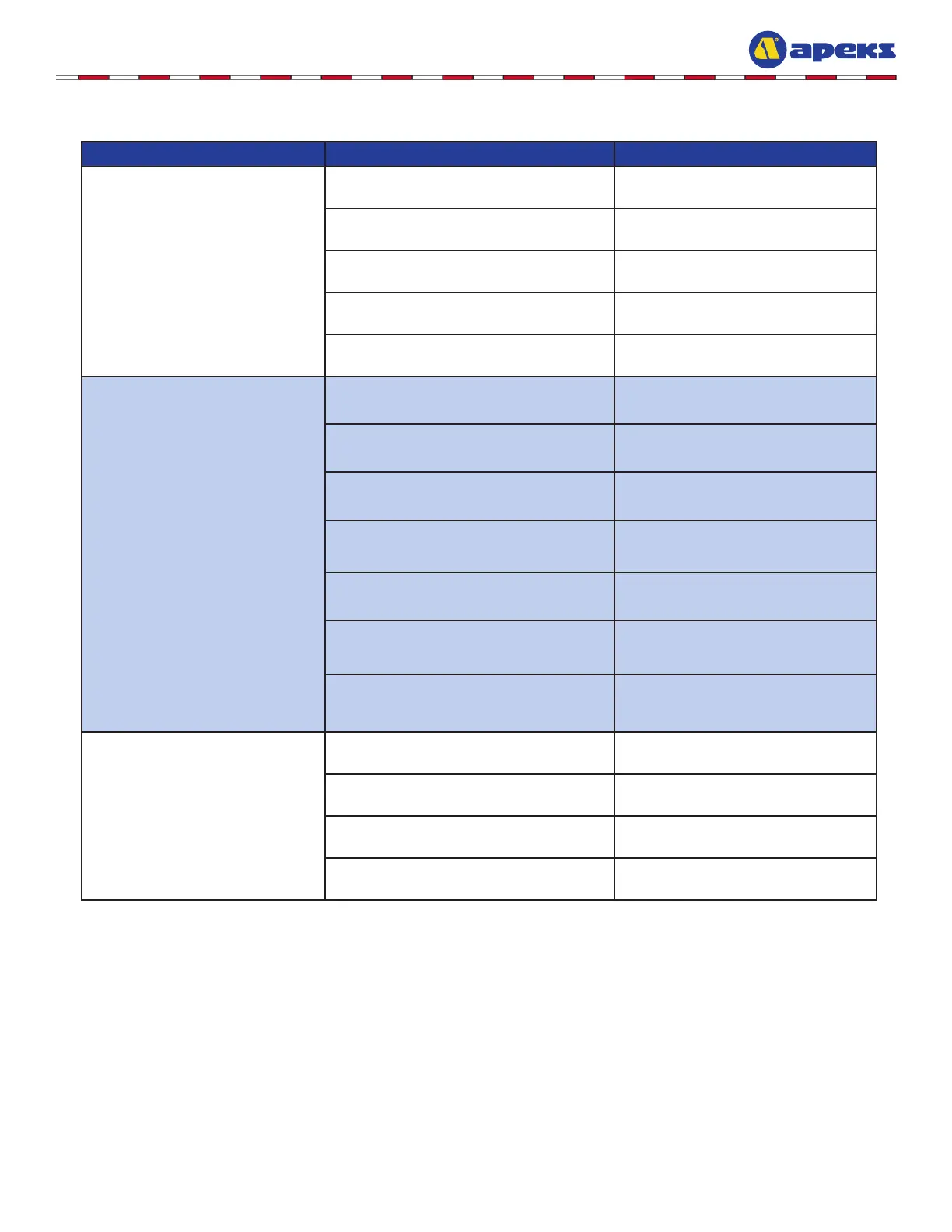

SYMPTOM POSSIBLE CAUSE TREATMENT

High Pressure Creep

(also causes second-stage leaks)

1. HP valve (11) worn or damaged. 1. Replace HP valve.

2. HP valve seat worn or damaged. 2. Replace body (5).

3. Turret bolt (15) internal wall dam-

aged.

3. Replace turret bolt.

4. HP o-ring (13) damaged. 4. Replace o-ring.

5. HP o-ring (17) damaged. 5. Replace o-ring.

External Air Leakage

or

Hydrostatic Diaphragm dis-

tended or burst

1. Blanking plug o-rings worn,

damaged or missing. (10,13,20).

1. Replace o-rings.

2. Diaphragm (3) worn or damaged. 2. Replace diaphragm.

3. Hydrostatic diaphragm worn or dam-

aged.

3. Replace hydrostatic diaphragm (25).

4. Diaphragm seating surface dam-

aged.

4. Replace body (5).

5. Diaphragm clamp (21) loose. 1. Tighten diaphragm clamp.

6. Connector o-ring (10) worn or dam-

aged.

2. Replace o-ring.

7. Turret bolt o-ring (16) worn or dam-

aged.

3. Replace o-ring.

Restricted Air Flow

or

High Inhalation Resistance

Through Entire System

1. Cylinder valve not completely open.

1. Open valve and check ll pres-

sure.

2. Cylinder valve needs service. 2. Switch to a different cylinder.

3. Filter (36) is clogged. 3. Replace lter.

4. Very low medium pressure.

4. Adjust MP to between 130-145

psi (9-10 bar).

TABLE 1: FIRST STAGE TROUBLESHOOTING GUIDE

14

Loading...

Loading...