14

15

FLIGHT First Stage Regulator Maintenance ManualFLIGHT First Stage Regulator Maintenance Manual

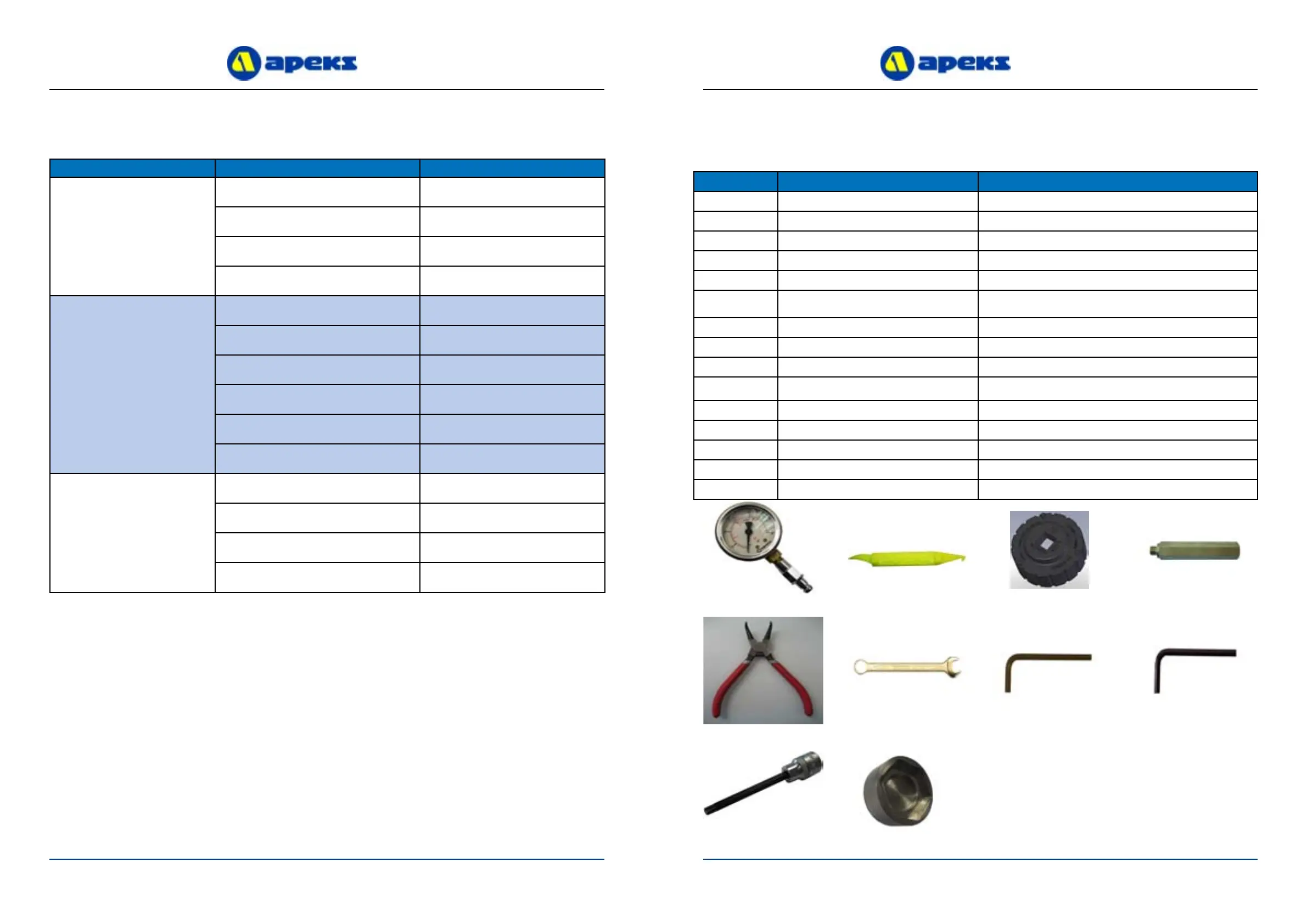

Table 1 - Troubleshooting Guide

SYMPTOM POSSIBLE CAUSE TREATMENT

High Pressure Creep

(also causes second stage leaks)

1. HP Valve (16) is worn or damaged.

1. Replace HP Valve.

2. ‘O’ ring inside HP Balance Chamber

(18) is damaged or worn.

5. Replace ‘O’ ring.

3. H.P balance chamber damaged 6. Replace balance chamber

4. HP Valve Seat in Valve Body (9) is worn

or damaged.

7. Replace Valve Body.

External air leakage

1. Blanking Plug ‘O’ rings (12,14) are

worn or damaged.

1. Replace ‘O’ Ring.

2. Diaphragm (6) worn or damaged.

2. Replace diaphragm.

3. Diaphragm seating surface

damaged.

3. Replace Valve Body (9).

4. Connector ‘O’ ring (20) worn or

damaged.

4. Replace ‘O’ Ring.

5. Diaphragm Clamp (4) loose.

5. Tighten Diaphragm Clamp to

specied torque.

6. ‘O’ rings on DIN Bolt (14,25) worn or

damaged.

6. Replace ‘O’ Rings.

Restricted air ow or high inhalation

resistance through entire system

1. Cylinder valve not completely open. 1. Open valve, check ll pressure.

2. Cylinder valve requires servicing 2. Switch to dierent cylinder.

3. DIN Filter (23) or Disc Filter (27) is

blocked.

3. Replace lter.

4. Very Low Medium Pressure.

4. Adjust Medium Pressure to

between 9 and 10 bar.

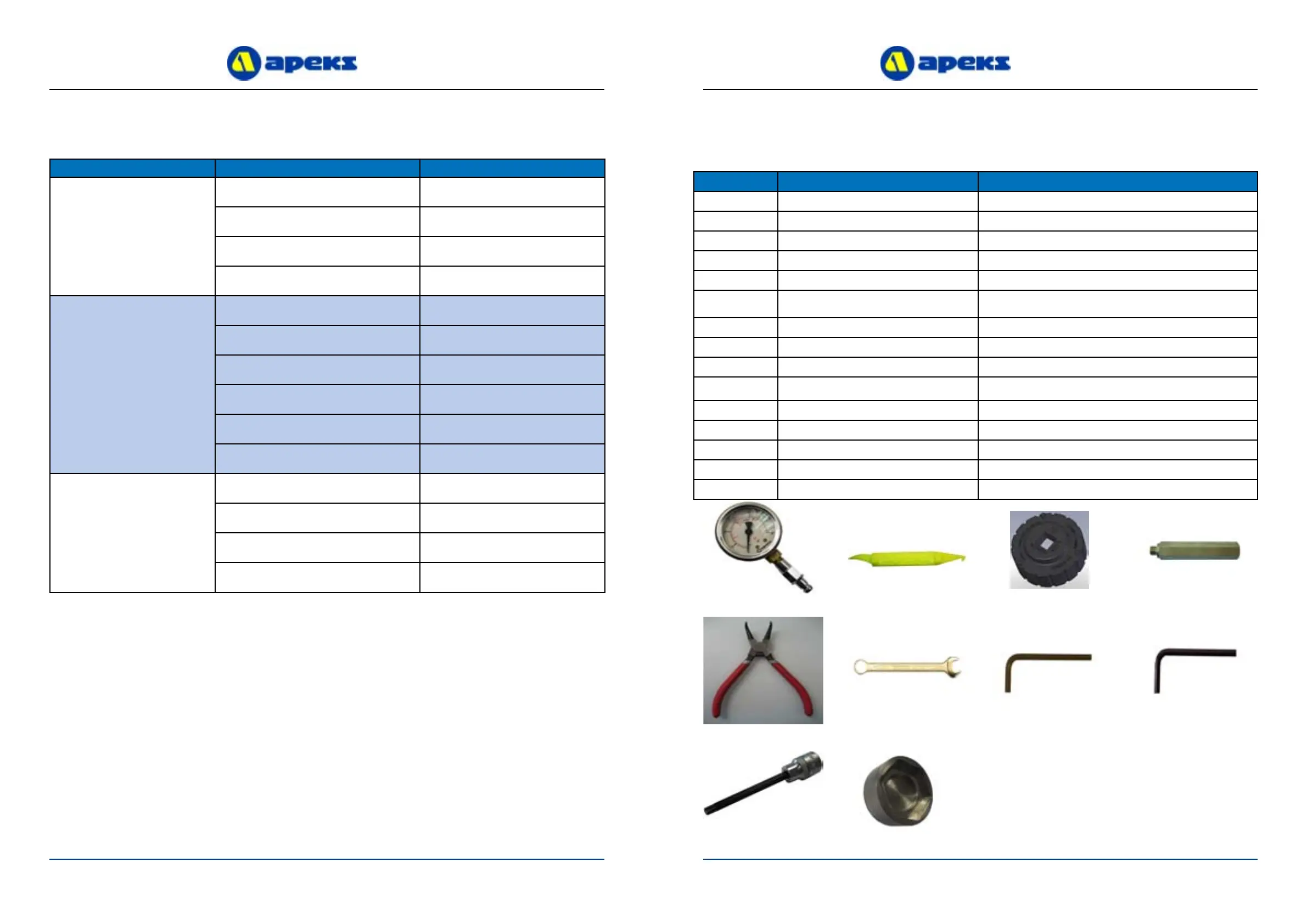

Table 2 - Recommended Tool List

PART NO. DESCRIPTION APPLICATION

AP0430 I.P. test gauge Intermediate pressure testing

AT79

‘O’ Ring removal pick ‘O’ Ring removal

AT71 Diaphragm Clamp Tool Removal of Composite Diaphragm Clamp

AT48 First Stage Work Handle Clamping Valve Body in Vice

AT24 Circlip Pliers Removal and installation of Circlip

n/a Torque wrench, Nm or lbf/ft

Installation of Composite Diaphragm Clamp, DIN

Connection and Yoke Connection

n/a 6mm Allen key bit for torque wrench Installation of DIN Bolt and Yoke Connector

AT34 11/16” spanner Hose Removal

AT37 5mm Allen key Blanking Plugs

AT38 6mm Allen key Removal of DIN Bolt

n/a 10mm Allen key Removal and Installation of Large Spring Adjuster

n/a 22mm Deep Socket Removal and installation of DIN Connector

AT74 Yoke Connector Socket Removal and installation of Yoke Connector

n/a 22mm Spanner Removal DIN Connector

n/a 232 or 300 bar Diving cylinder Testing of regulator

AP0430

AT34

AT24

AT79

Notes:

1. Photos not to scale.

2. Actual tools may dier

from photos.

AT48

AT37

AT38

AT71

6mm Allen Key Bit

AT74

Loading...

Loading...