E

N

G

Toreducetheriskofinjury,onlyARBORTECH,

accessories should be used with this product.

Recommended accessories for use with your tool

are available at extra cost from your local dealer or

authorised service centre.

Repairs

If you need any assistance in locating any

accessory, or general tool query please contact

ARBORTECH. www.arbortech.com.au

Brushes

TheAS170isttedwithAuto-cutoffbrushes.When

the brushes are worn below minimum length they

stop tool operation reducing internal motor damage.

Contact your local dealer or authorised service

center for brush replacement.

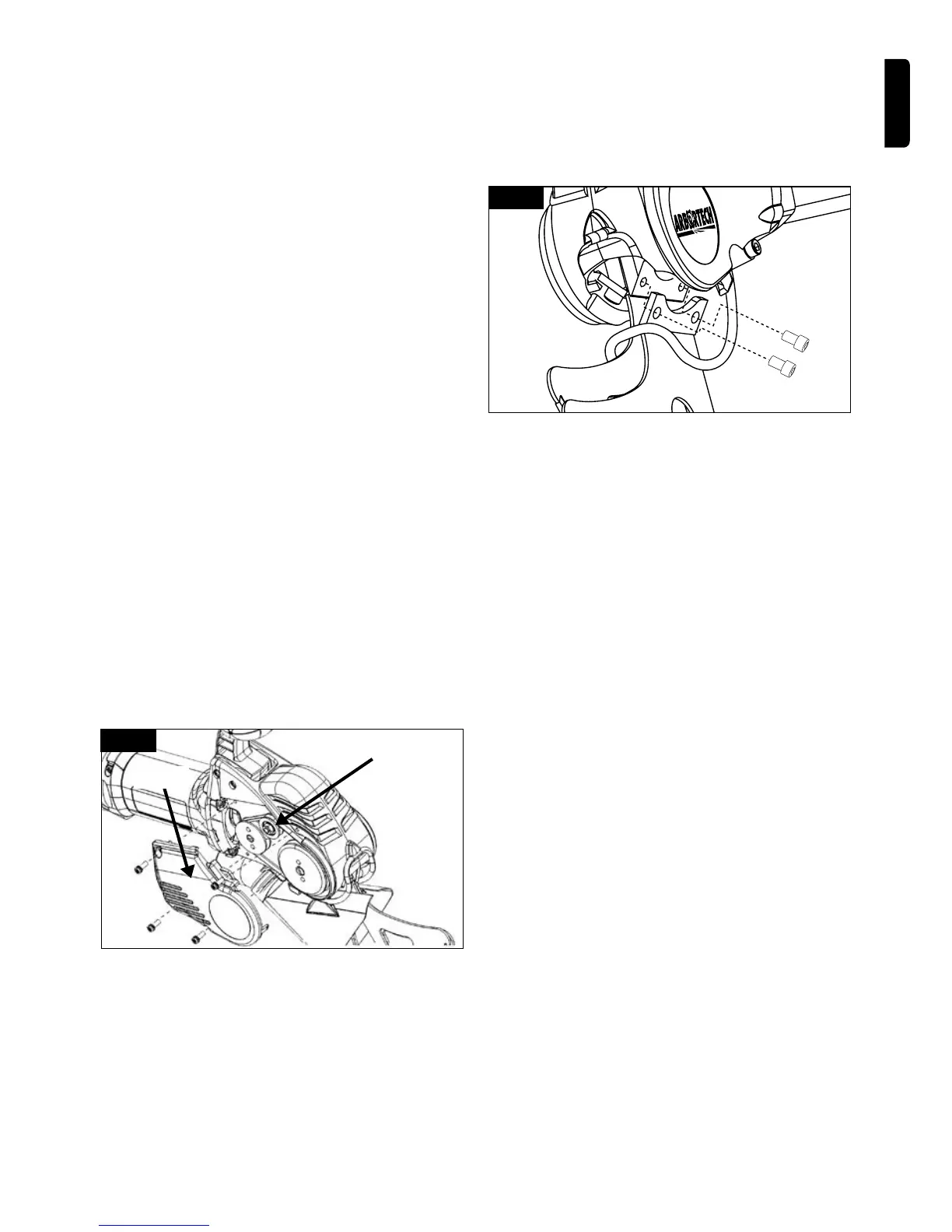

7.2 V Belt and Pulleys

CAUTION: The V-Belt should be re-tensioned after

therst5hoursofuse.

To access these items, remove the 4 screws holding

the plastic cover on the right side of the tool (see

g.14).Inspectthebeltforcorrecttensionandsigns

of damage. If tensioning is required, loosen the the

tension idler nut (one turn only). Slide the tension

idler outward to increase the tension to the value

noted in the General Specifications in Section

3 and re-tighten. If belt replacement is required,

loosen the tensioner idler, replace the belt and re-

tensiontheidlerasspecied.

Tension Idler

Cover

Fig.14

If excessive slipping has occurred, the pulleys

can become worn. A worn pulley is evidenced by

thegroovehavinglostitswelldened“V”shape,

resulting in a rounded or flattened groove. To

replace either pulley, contact your ARBORTECH

authorised service centre.

7.3 Blade Mount Bolts and Threads

The blade cap screws should be regularly checked

for correct torque (18Nm.)(13.2 ft lb).Whenever

blades are changed, the bolt and conrod threads

should be checked to ensure they are not worn or

lledwithdebris.UseonlygenuineARBORTECH

spares and do not lubricate bolts, threads or conrod

mating surfaces.

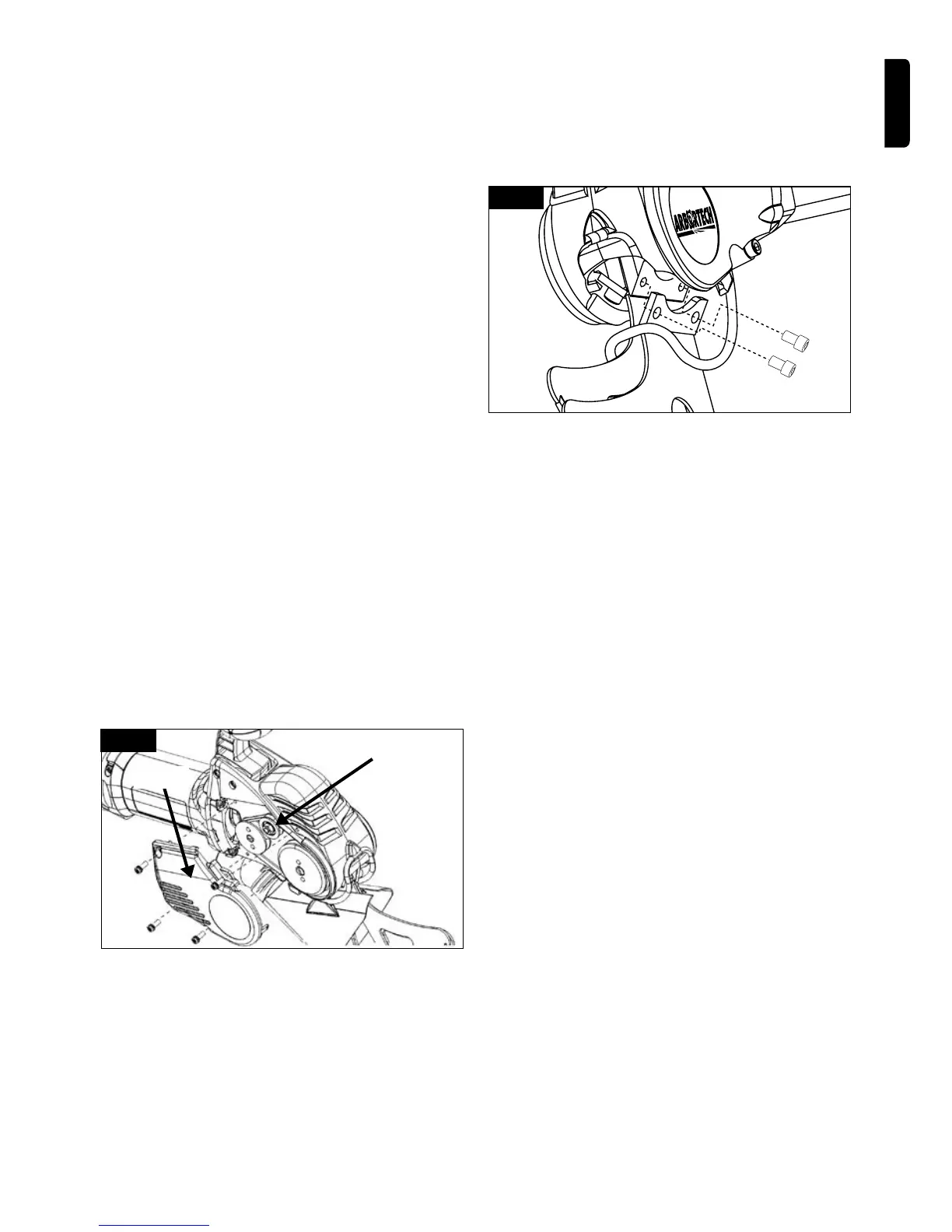

Fig.15

CAUTION: DO NOT operate the tool with loose

blades. If blades should come loose while

operating, the blade mounts and threads can

becomedamaged,requiringsignicantrepairsto

the tool.

7.4 Tooth Sharpness

With use, the blades will become dull and the

cutting performance will decrease. This can be

largely restored by re-sharpening the teeth. To

re-sharpen blade teeth, use the ARBORTECH

Sharpening disk (BLA.FG.SHARP001) Occasionally,

if very hard materials are cut, or the teeth impact a

hard surface at an odd angle, teeth may become

chipped or broken. The blades can still be used,

but cutting performance will be reduced.

If“blueing”ofthebladeperipheryoccurs,the

blades are running too hot. This occurs when the

blades become worn, too much force being used,

insufcient“sweeping”motionbytheoperator,or

material being too hard.

IMPORTANT To ensure optimal performance and

reduce load on motor, Blades should be kept sharp.

8. ACCESSORIES

8.1 Dust Extraction

TheAS170shouldbettedwithadustextraction

funnel,whichsignicantlyreducesairborneand

heavy dust when used correctly. It consists of a

ttingattachedtotheundersideofthealuminium

housingandanadjustableextractionfunnelwhich

isreplaceable.Thedustextractionttinghasa

standard 30mm (1 3/16”) bore.

eNGLISH 10

Loading...

Loading...