E

N

G

before engaging the work piece.

6. Never start or operate the tool with fingers or

other objects through the holes in the blades.

7. Use care when handling blades during and

after use. The blades and some areas of the tool

become hot in use.

8. Always ensure that before cutting there are

no hazards such as electrical wiring, pipes or

insulation in the area to be cut.

9. Allow for resting periods to ease the effect

of the vibration of the tool. Use work gloves to

minimise vibration effect on the body.

10. Ensure the dust extraction equipment is

connected and properly used.

11. Keep handles dry, clean and free from oil and

grease.

12. If the guard or other parts appears to be

damaged, it should be carefully checked to

determine that it will operate properly and perform

its intended function.

13. The use of any accessory or attachment other

than those recommended in this instruction manual

maypresentariskofpersonalinjury.

14. Do not force the tool. It is designed to

operate with moderate effort. Overheating of the

drive system and motor can occur if the tool is

overloaded.

15. Always operate the tool holding it with both

hands.

SYMBOLS The following show the symbols used

in this manual

Class 2 Construction (Double

Insulation used throughout, no

provision for earthing.)

VAC volts alternating current

A amperes

Hz hertz

W watt

N

0

no load speed

rpm revolutions per minute

dB decibels

Nm newton meters

m meters

SYMBOLS The following show the symbols used

in this manual

m/s meters per second

mm millimeters

kg-m kilogram meters

ft-lb foot pounds

4. FUNCTIONAL DESCRIPTION

4.1 AS170 TOOL DESCRIPTION

The AS170 is designed to cut rigid materials

suchasmortar,clayredbricks,plasterboard,

breboard,weatherboardandwood.TheAS170

uses a variety of blades to suit the material being

cut. Blades may also be changed to suit the

required depth or length of cut.

The blades are driven via conrods and a camshaft,

which is belt-driven. The V-belt is designed to allow

someslipincaseofthebladesjamming.The belt

tension must be checked after the first 5 hours

of use. It is easily tightened by removing the plastic

coverandistensionedusingtheadjustableidler

pulley (see section 7.2).Blades are mounted to the

conrods using high tensile Allen™ head bolts.

A replaceable metal guard is provided to limit the

maximum cutting depth and prevent the blade

mounts from damaging the surface of the material

being cut. Shock and vibration to the operator are

reduced by a rubber-mounted top handle. The top

handle is also designed for comfort when used in

a variety of cutting orientations. The rubber bushes

on the top handle can be replaced if they become

worn or damaged.

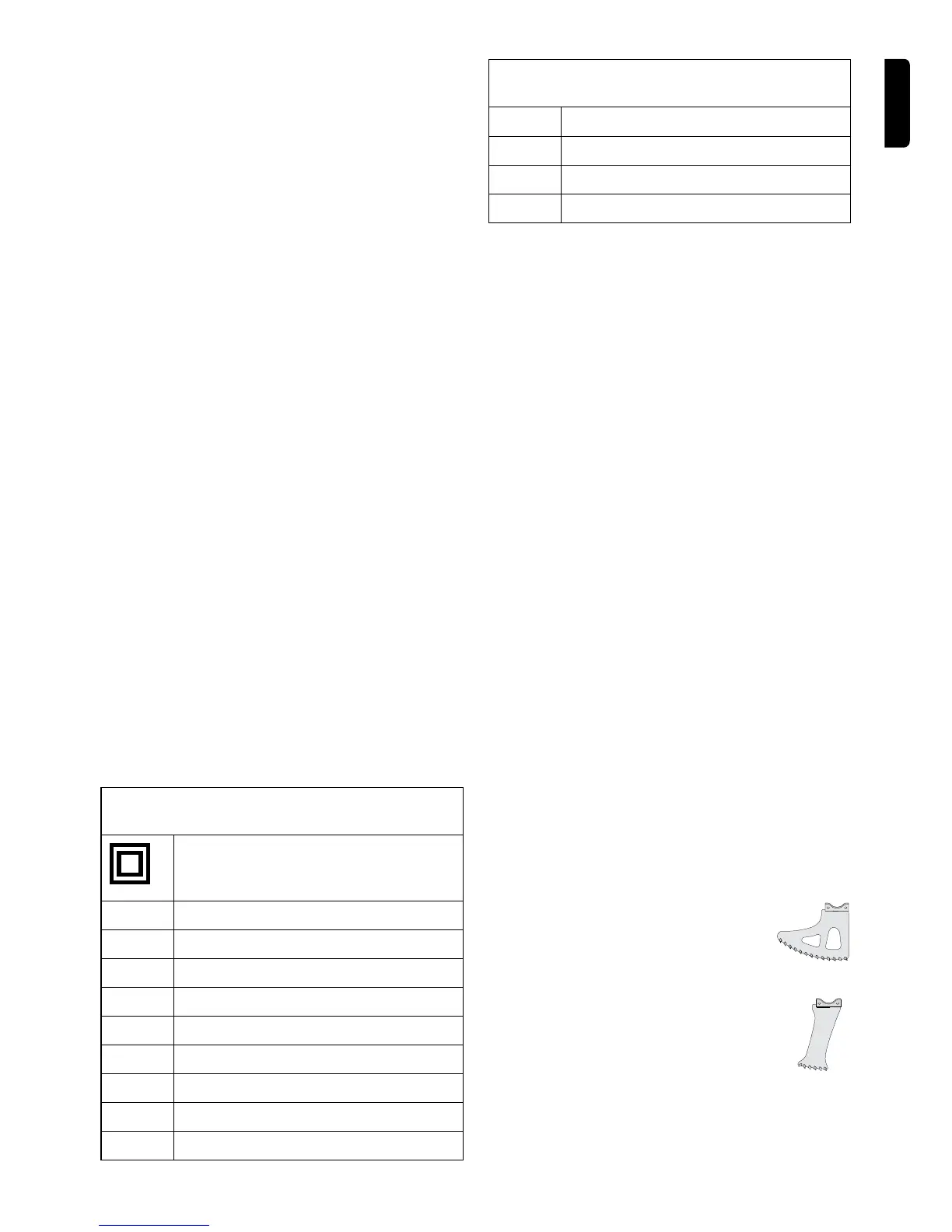

4.2 BLADE DESCRIPTION

The AS170 uses a variety of blades to cut different

materialsanddifferentproles.

General Purpose blades use Tungsten

Carbide teeth and are suited for working

generalmasonryand“intheground”cutting.

General Purpose blades are designed to cut

to a depth of 115mm (4 1/2”).

Plunge blades use Tungsten Carbide teeth

and have a maximum cutting depth of

120mm (

4

3/4

”). Mortar plunge blades can cut

slots of 75mm (3”) in length.

eNGLISH 4

Loading...

Loading...