E

N

G

eNGLISH 13

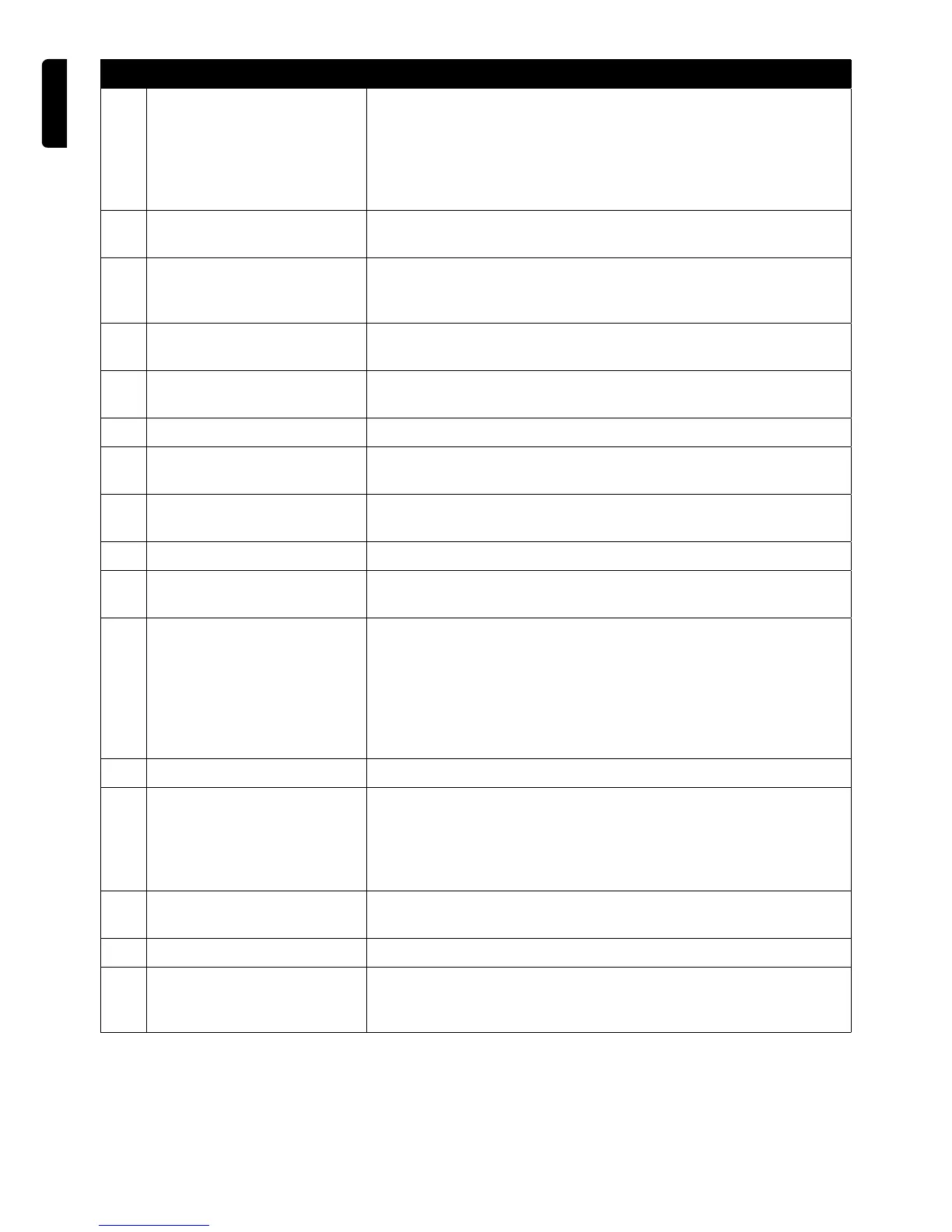

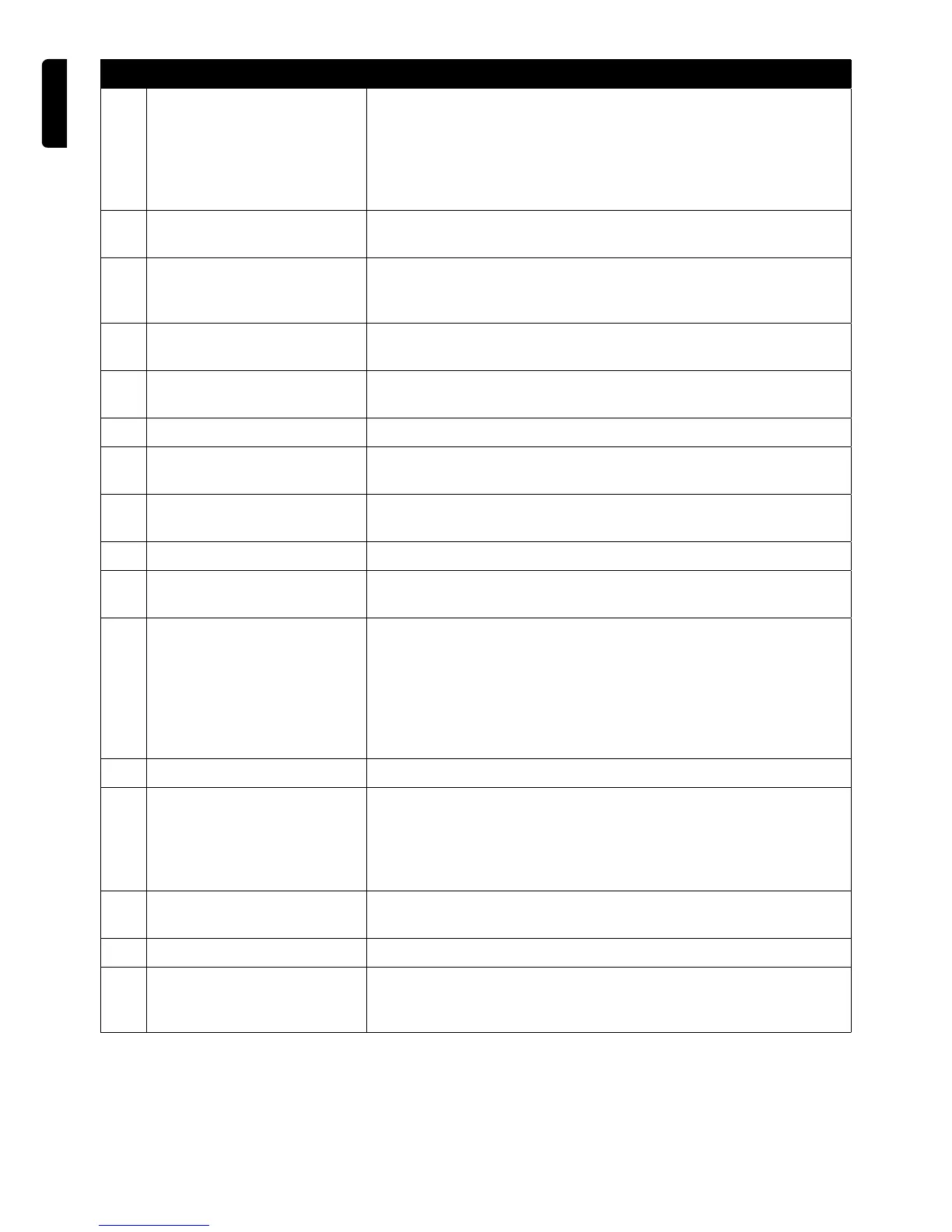

ITEM

SYMPTOM CHECK/REMEDY

2 Noisy operation or unusual

vibration

•Bladesloose-tightenblademountbolts

•Bladefailure-replacebladeset

•Leafspringfailure-contactauthorisedservicecentre

•Bearingfailure-contactauthorisedservicecentre.

•Gearboxfailure-contactauthorisedservicecentre.

•Handlerubbermountsdamagedorworn-replace.

3 Handle rubber mounts

damaged or worn

•replace

4 One or both conrods/blades

loose, even when mounting

bolts tightened

•Leafspringfailure-contactARBORTECHauthorisedservicecentre.

5 Tool running and blades not

moving

•Loosebeltorbrokenbelt-re-tensionorreplaceasnecessary.

•Wornbelt-replacebelt.

7 Blades continually comming

loose

•Checkthebladeboltholes.Ifboltholesareelongatedreplaceblades

8 Worn pulleys •contactARBORTECHauthorisedservicecentre.

9 Slow cutting performance •Teethworn,chippedorlost.Sharpenorreplaceblade.

•Beltslipping-seeSymptom4.

10 Blades rubbing against each

other with excessive force

•Attemptingtocutmaterialwhichistoohard.

11 Blades continually coming loose •Checkthebladeboltholes.Ifboltholesareelongatedreplaceblades.

12 Blades rubbing together with

excessive force.

•Removeblade/sandbendslightlytocorrect.

13 Blade teeth chipped or lost.

·

•Occursoccasionallyifhardmaterialisencountered,orifthe“backside”

of teeth are impacted.

•Carenottakeninsettingtooldownonteethonhardsurfacesorloosein

tool box.

•Wornbladeswillstarttobecomehotincertainareas,causingteethtode-

bond - replace blades.

•Materialtoohard.

14 Loose top handle. •Wornordamagedrubberbushes-replace.

15 Blades“blueing”. •Wornteeth-replaceblades.

•Excessiveforcebeingused.

•Insufcient“sawing”motionbytheoperator.

•Materialtoohard.

Blades rubbing together with excessive force (see section 8).

16 Blade mounting bolts not

tightening fully.

•Threadsonboltsstripped-replaceboltsnottightening.

17 Threads on tool stripped •ContactyourARBORTECHauthorizedservicecenter.

18 Tool will not run. •TheAS170isttedwithAutocutoffbrushes.

•Checkbrushesarenotdamagedorexcessivelyworn-replaceContact

your ARBORTECH authorised service centre.

Loading...

Loading...