13

The workpiece is not cut fully. This may be caused by:

1) The cutting current is too low.

2)

The cutting speed is too high.

3)

The electrode and nozzle of the torch are burned.

4) The workpiece is too thick.

Molten slag drops from the bottom of workpiece. This may be caused by:

1) The cutting speed is too low.

2)

The electrode and nozzle of the torch are burned.

3)

The cutting current is too high.

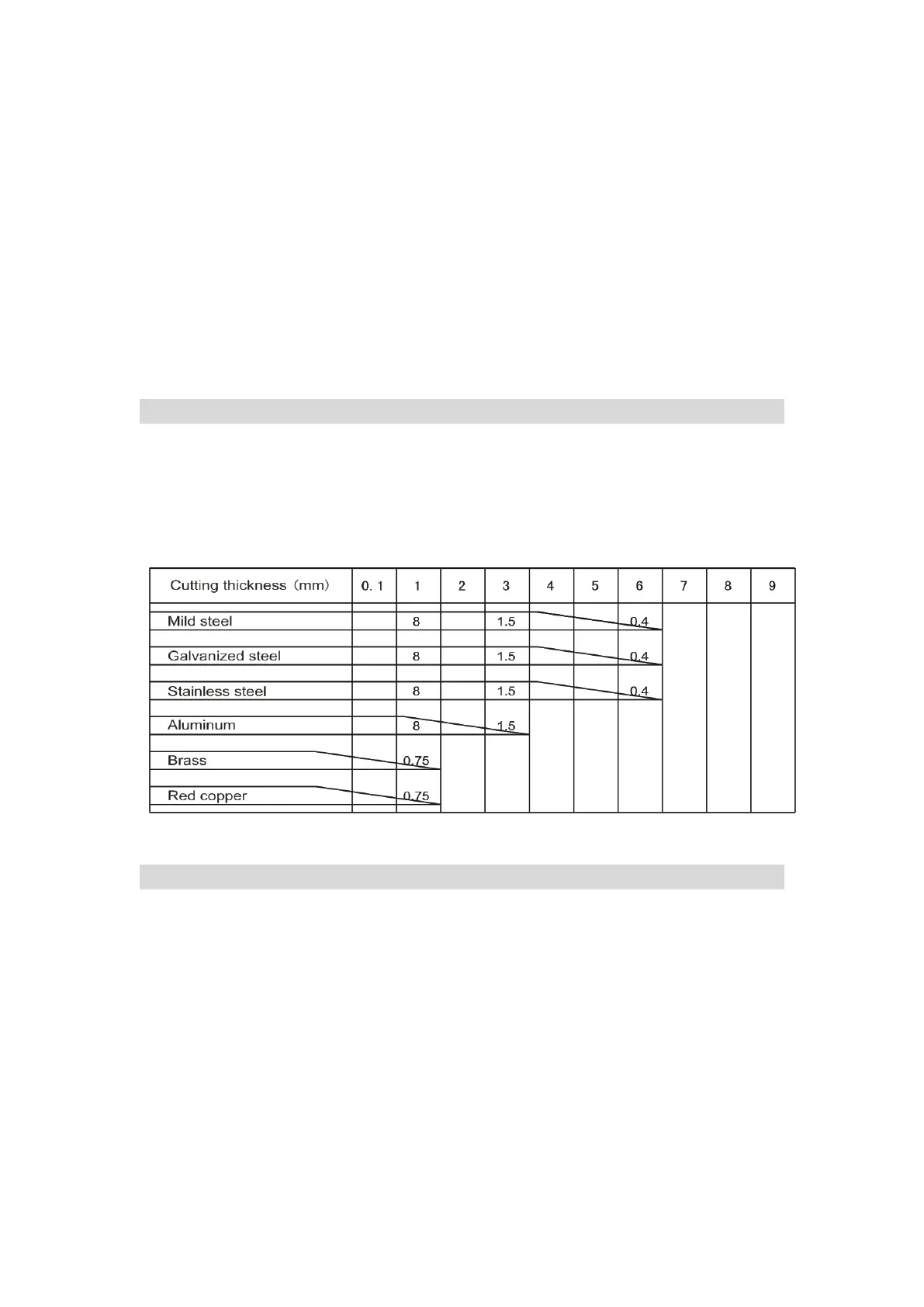

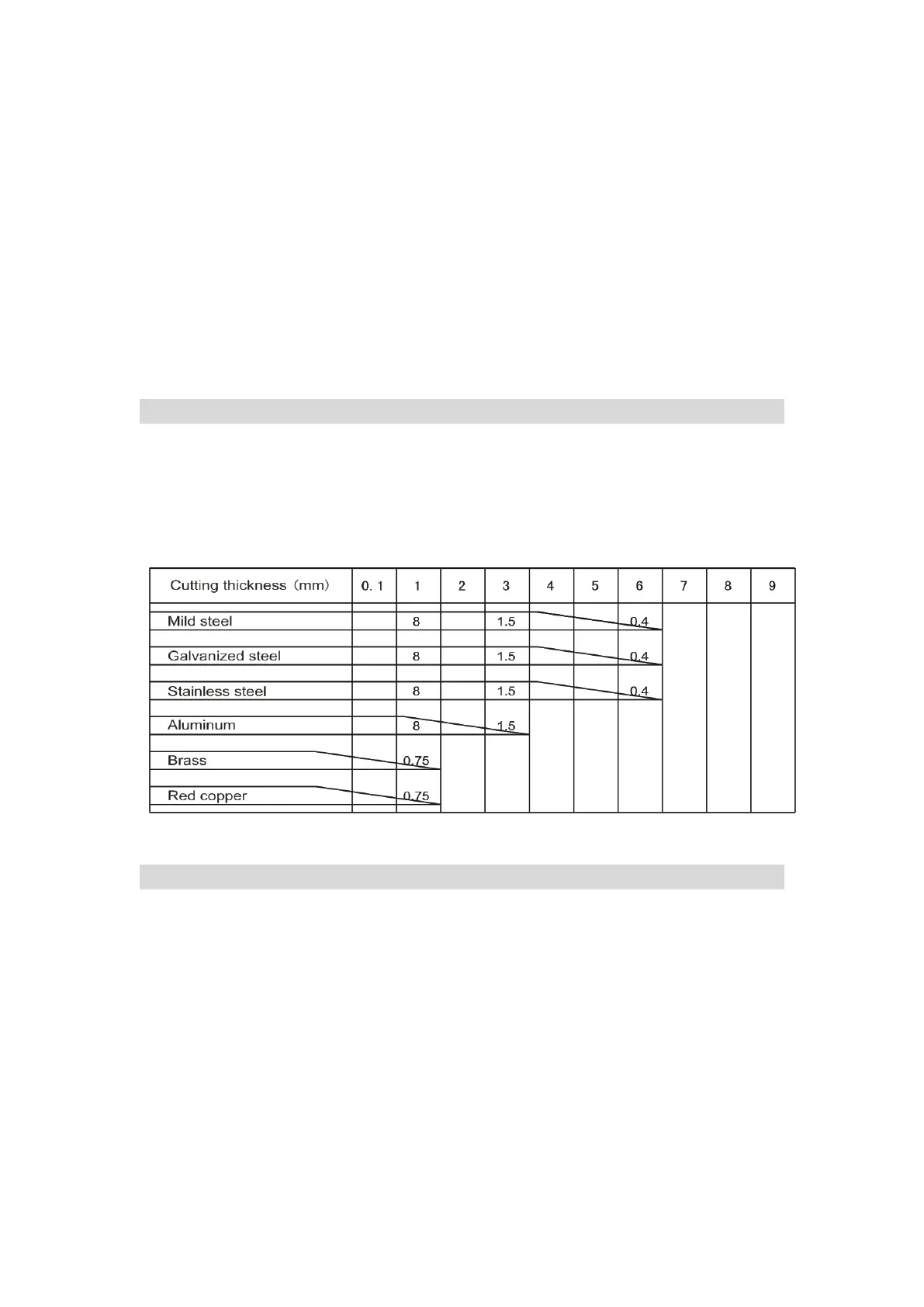

4.4 Cutting parameters table

Select proper current according to the cutting parameters table, workpiece material,

cutting thickness and cutting speed, etc. (The figure in the below table is an

approximation.)

Cutting speed (meter/min) when cutting current is 50A

4.5 Replacement of electrode and nozzle

When the phenomena below occur, the electrode and nozzle should be replaced.

Otherwise, there will be strong arc in the nozzle, which will break down the electrode and

the nozzle, or even burn the torch. Nozzles of different models are different, so ensure the

nozzle is of the same model when replacing it.

1) Electrode wear>1.5mm

2) Distortion of the nozzle

3) Cutting speed declining, arc with green flame

4) Difficult in arc ignition

5) Irregular cut

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...