9

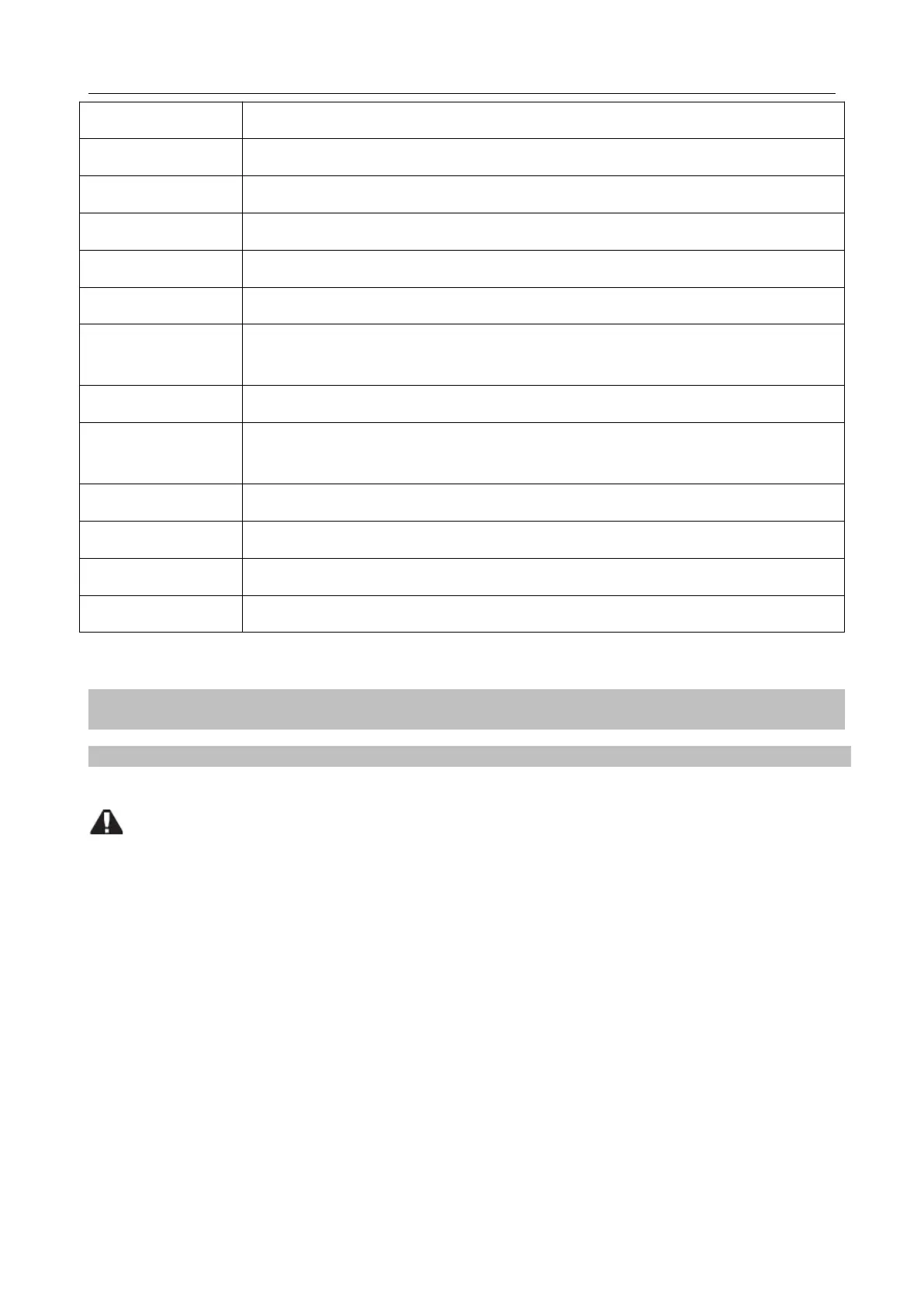

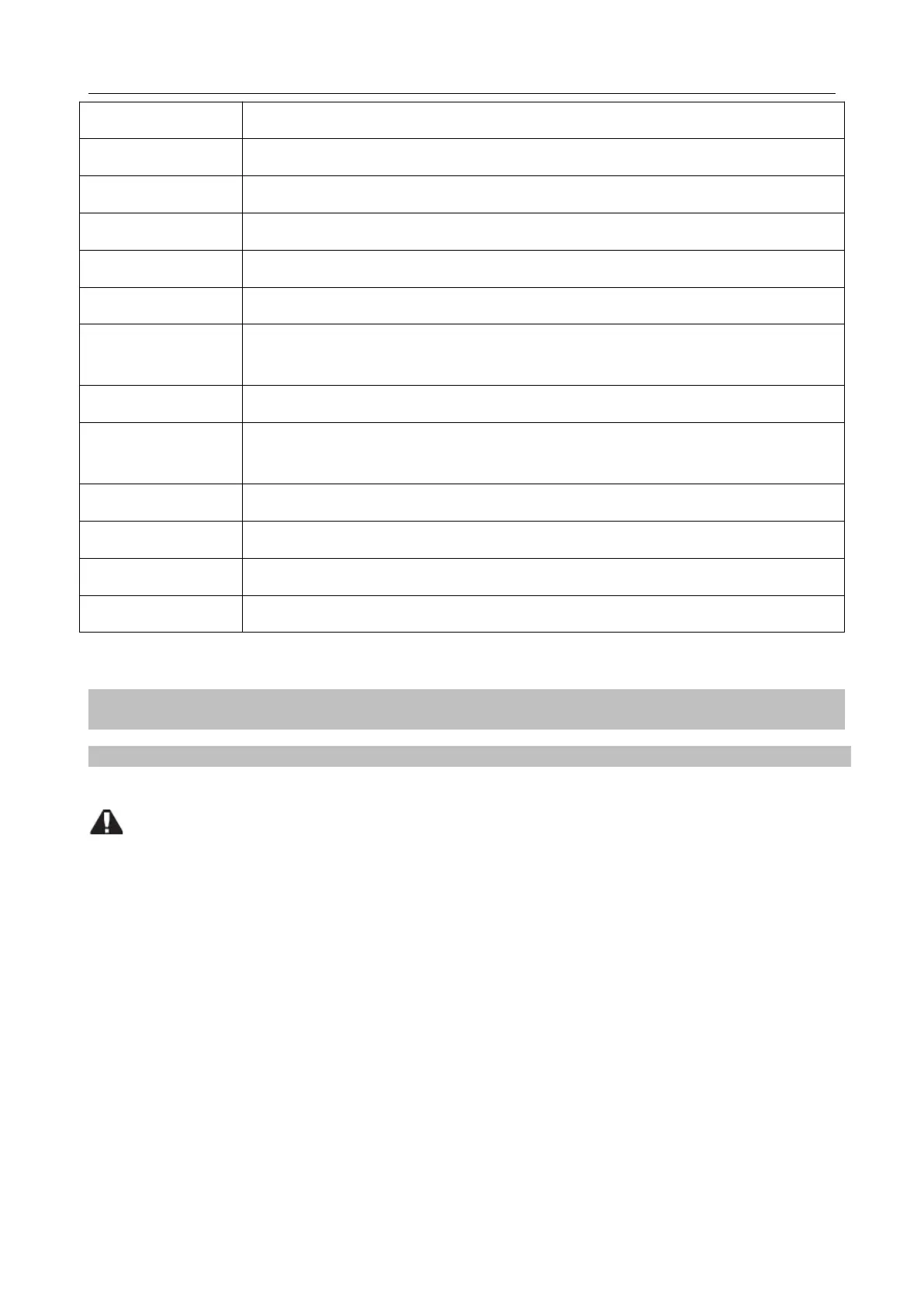

TIG 4T 4T Welding mode.

DownSlope This indicates the time taken from the peak current to the arc striking current.

PostGas This indicates the shielding gas post-flow time.

Current This indicates the value of output current.

A Unit of current.

s Unit of time.

Welding mode

button

For MMA/2T/4T welding mode conversion.

Preference button For Down slope/Post Gas/Current conversion.

Control mode

button

For Panel/Remote conversion.

Power wire For power supply input.

Power switch To control the ON/OFF of the input power of the machine.

Fan For heat dissipation through forced air cooling.

Gas nut Used to connect external gas.

4. INSTALLATION AND CONNECTION

4.1 Installation requirements

Environment requirements

Please pay attention to the following when choosing installation site:

Please avoid environment which contains too much dusts or metal powder.

Avoid installation in area which is with corrosive or explosive gases.

Ambient temperature should be within

-

10

℃~+

40

℃

;Please reinforce radiation or lessen

power machine operation when temperature is over 40

℃

.

Installation should be carried out in dry environment with humidity less than 90%.

Avoid welding in the open air with strong wind; please install windscreen if necessary, or else

welding performances may be affected.

Please consult and confirm in advance if there is any special installation requirement.

If the Welding power is paced on tilt plane, pay attention to avoid it topple over.

The Welding power is forbidden to use thaw pipe.

Digital Welder Expert, Know You More

https://www.arccaptain.com

Loading...

Loading...